Chapter 3: Configuration and Parameters

Page 3–51Stellar

®

SR55 Series Soft Starter User Manual – 1st Ed, Rev F – 09/18/2019

parameTer deTails – “i/o” menu of parameTers (ConTinued)

P12.2 – Analog Input: Scaling Level Type:

Description:

Read/Write

Allows the selected function to be scaled. The selected function will change in proportion with

the input.

• The function will be at its “Scaling Level” when the input is at its maximum.

Range: Modbus Decimal Value: Default:

0 – 16384 linear scale ( 1 = 0.006104 % )

0% – 100% = (0 – 16384)

x% / 0.006104% = Modbus dec. value

EX: Modbus value of 5250 = 32.05%

16384

Modbus Address: Modbus Format:

9728 ( 2600 hex ) 16-bit unsigned

Touchscreen Menu Path:

Home → I/O → Analog Inputs → Scaling Level

i/o “analog ouTpuT” parameTers

P13.0 – Analog Output Type Hold. Reg. Type:

Description:

Read/Write

Defines the function of the Analog Output (AO).

Range: Modbus Decimal Value: Default (decimal):

• 0–10V : The output voltage varies from 0 to 10V.

• 4–20mA : The output varies from 4 to 20mA.

• 0

• 1

• 0–10V (0)

Modbus Address: Modbus Format:

8960 ( 2300 hex ) 16-bit unsigned

Touchscreen Menu Path:

Home → I/O → Analog Outputs → Analog Output Type

P13.1 – Analog Output: Select Function Hold. Reg. Type:

Description:

Read/Write

Allows the Analog Output to be mapped to different functions. The output will change in

proportion with the selected function.

• By default the output will be at a maximum when the selected function equals its max value.

Range: Modbus Decimal Value: Default (decimal):

• Off

• Current Measured

• Overload

• Overload SCR

• P-Total

• 0

• 514

• 522

• 161

• 542

• Off (0)

Modbus Address: Modbus Format:

9024 ( 2340 hex ) 16-bit unsigned

Touchscreen Menu Path:

Home → I/O → Analog Outputs → Select Function (Analog Output)

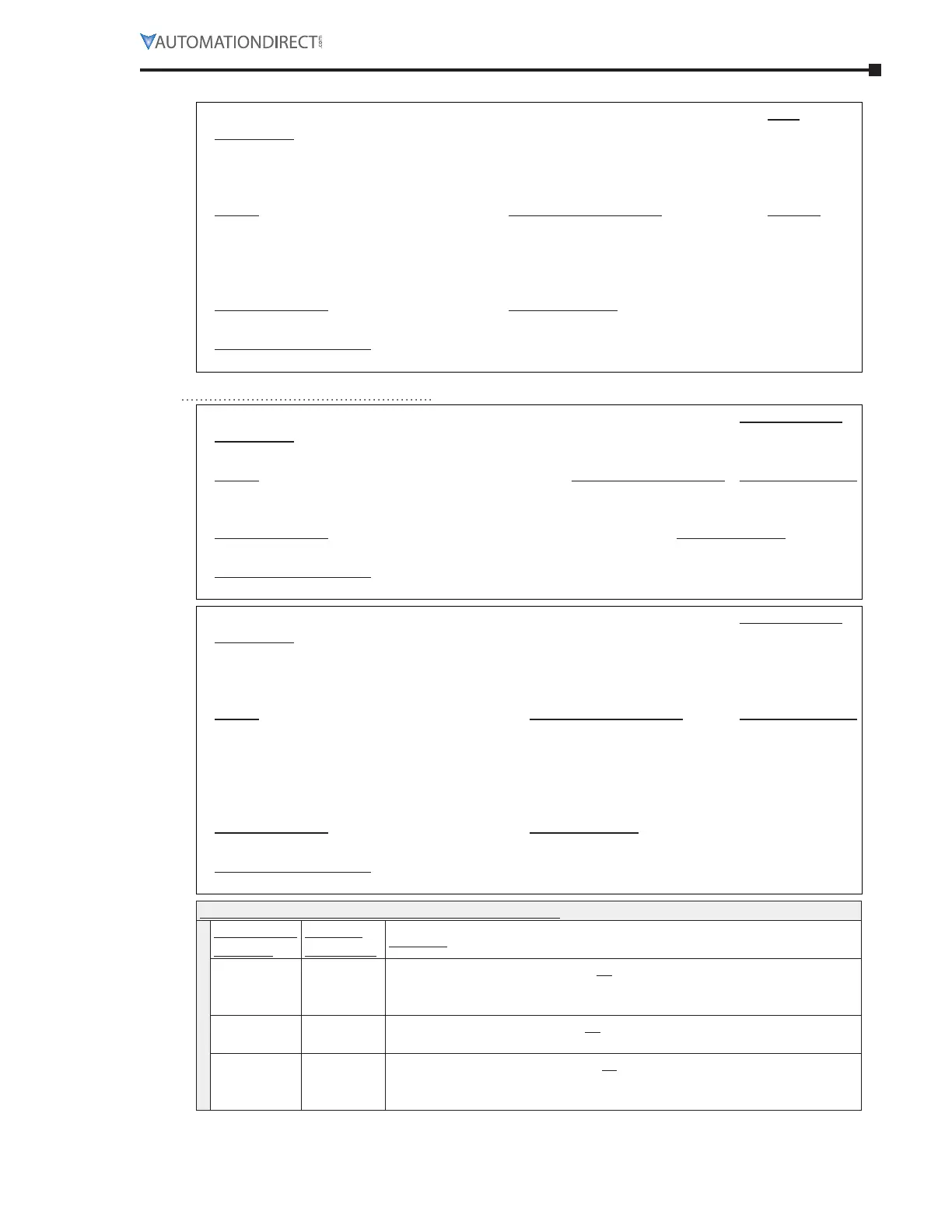

Examples of P13.1 Analog Output Fuction Selections

AO Function

Settings:

Modbus

Dec. Value:

Example:

Current

Measured

514

AO shows P15.5 Current I

rms

. Ex: This value can be fed out to a panel

ammeter for panel designs, or can be used as feedback to a PLC

system for monitoring or management system such as SCADA, etc.

Overload 522

AO shows P15.20 Overload. Ex: This value can be fed back to a PLC

system for monitoring or management system such as SCADA, etc.

P-Total 542

AO shows P15.8 True Power P. Ex: This value can be fed out to a panel

power meter for panel designs, or can be used as feedback to a PLC

system for monitoring or management system such as SCADA, etc.

Loading...

Loading...