www.balluff.com 9english

4

Product description (continued)

4.2 Function

To determine the position of a plant component, a magnet

is connected to the component. Together they are moved

along a waveguide located inside the BTL.

An internally generated INIT pulse interacts with the

magnetic field of the magnet to generate a torsional wave

in the waveguide which propagates at ultrasonic velocity.

The component of the torsional wave which arrives at the

end of the waveguide is absorbed in the damping zone to

prevent reflection. The component of the torsional wave

which arrives at the beginning of the waveguide is

converted by a coil into an electrical signal. The position of

the magnet and thus at the same time that of the plant

component is determined from the running time of the

shaft.

The measurement value is output as a 32-bit value with

sign relative to the zero point.

Number of magnets

Operation is possible with one or two magnets, whereby

the number can be set to one magnet or used flexibly.

4.3 Display elements

Signal Meaning

Red flashing,

1Hz

This signal occurs if a measurement

error occurs. The measurement value

is unknown due to an error or outside

of the measuring range.

Red, static General error.

Green,

alternating with

LED off in a ratio

of 10:1, 1s

period

IO-Link communication is active.

The device is ready.

Green, static The device is ready.

Tab. 4-1: LED display

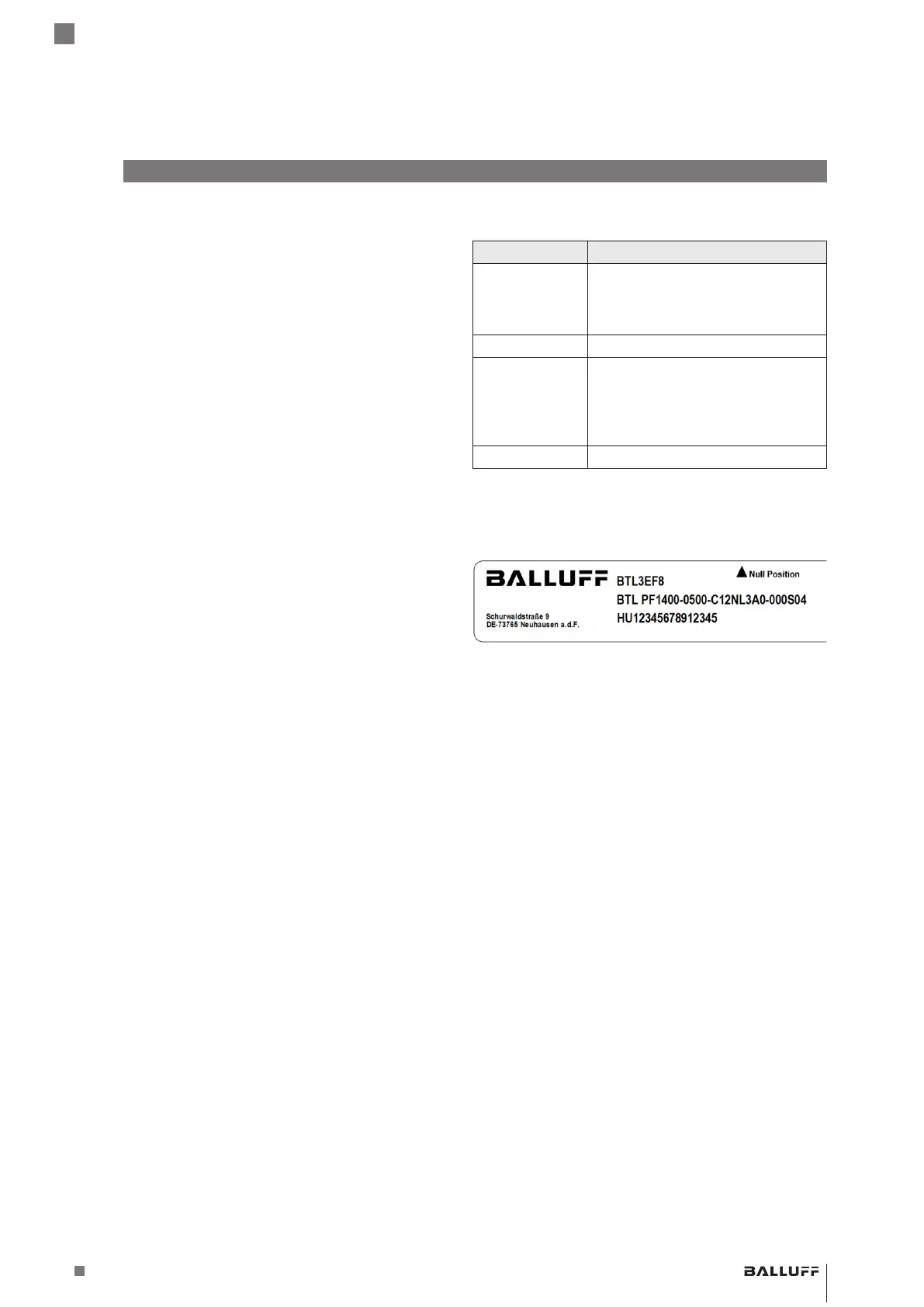

4.4 Part label

1)

2)

3)

1)

Order code

2)

Type

3)

Serial number

Fig. 4-2: Part label (section, example)

BTL PF _ 400- _ _ _ _ -C12NL _ _ -0-000S04

Magnetostrictive Linear Position Sensor – Profile Style

Loading...

Loading...