10 english

5.1 Installation

NOTICE

Improper installation

Improper installation can compromise the function of the

BTL and result in damage.

► Ensure that no strong electrical or magnetic fields are

present in the direct vicinity of the BTL.

► Be sure to maintain the specified distances and

separations.

For dimensions, see Fig. 4-1 on page8.

Any orientation is permitted. Mount the BTL on a level

surface of the machine using the provided mounting

clamps and cylinder-head screws.

In order to avoid resonant frequencies caused by

vibrations, we recommend positioning the

mounting clamps at irregular intervals.

The magnetostrictive linear position sensor is electrically

isolated from the machine with the supplied insulating

bushes (see Fig. 4-1 on page8).

1. Guide the BTL into the mounting clamps.

2. Attach the BTL to the base using mounting screws

(tighten screws in the clamps with max.2Nm).

3. Install the magnet (accessory).

The magnetostrictive linear position sensor in

profile housing is suitable both for floating, i.e.

non-contacting magnets (see Fig. 5-1 to Fig. 5-8)

and for captive magnets (see Fig. 5-1 and

Fig. 5-2).

5

Installation and connection

5.2 Captive magnets

Note when installing the magnet:

– Avoid lateral forces.

– Connect the magnet to the machine member with a

joint rod (see Accessories on page18).

– When using multiple magnets a minimum separation of

65 mm must be maintained between them

(seeFig. 5-3).

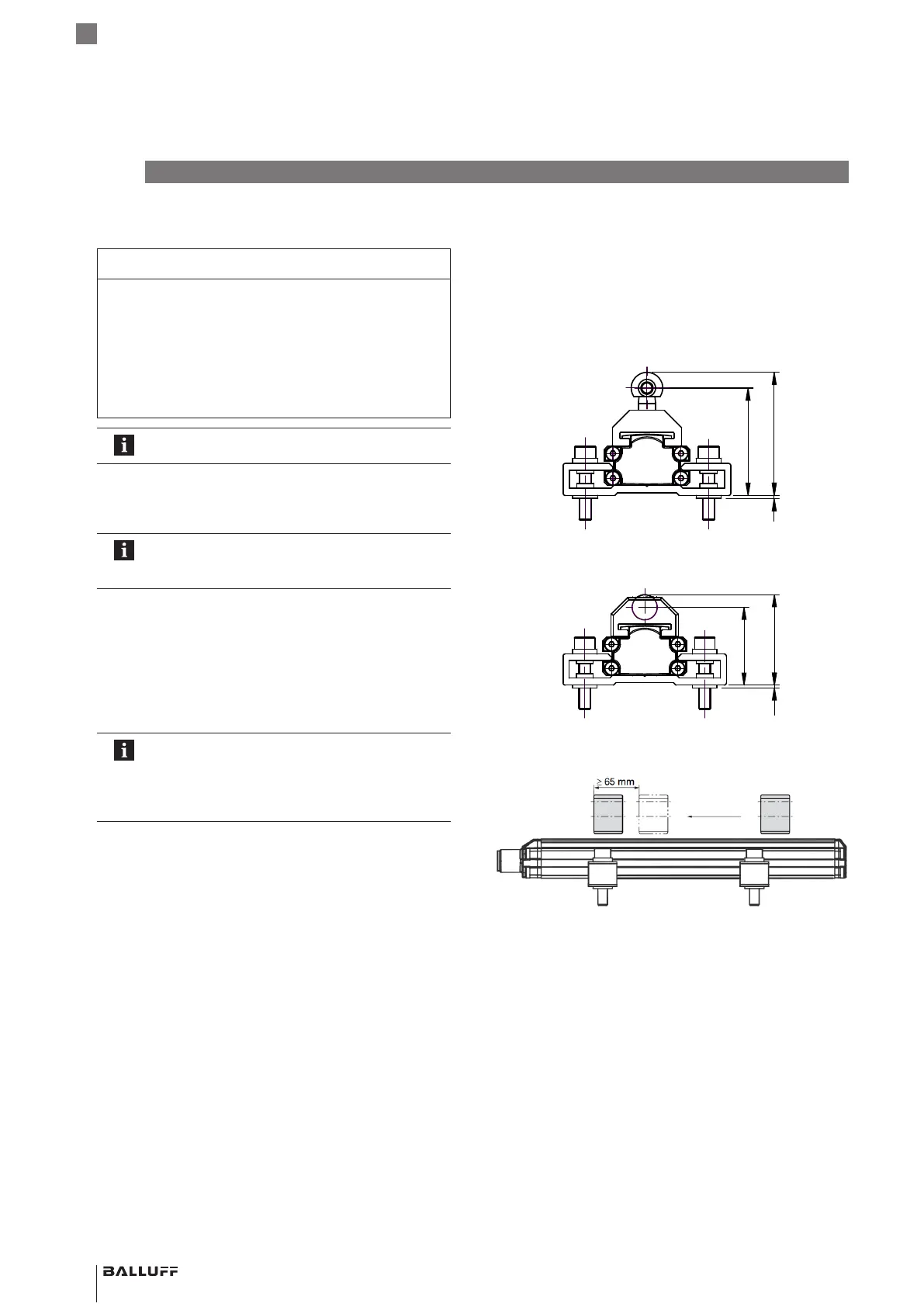

Fig. 5-1:

1

44

50.4

Dimensions and spacing with magnet BTL5-F-2814-1S

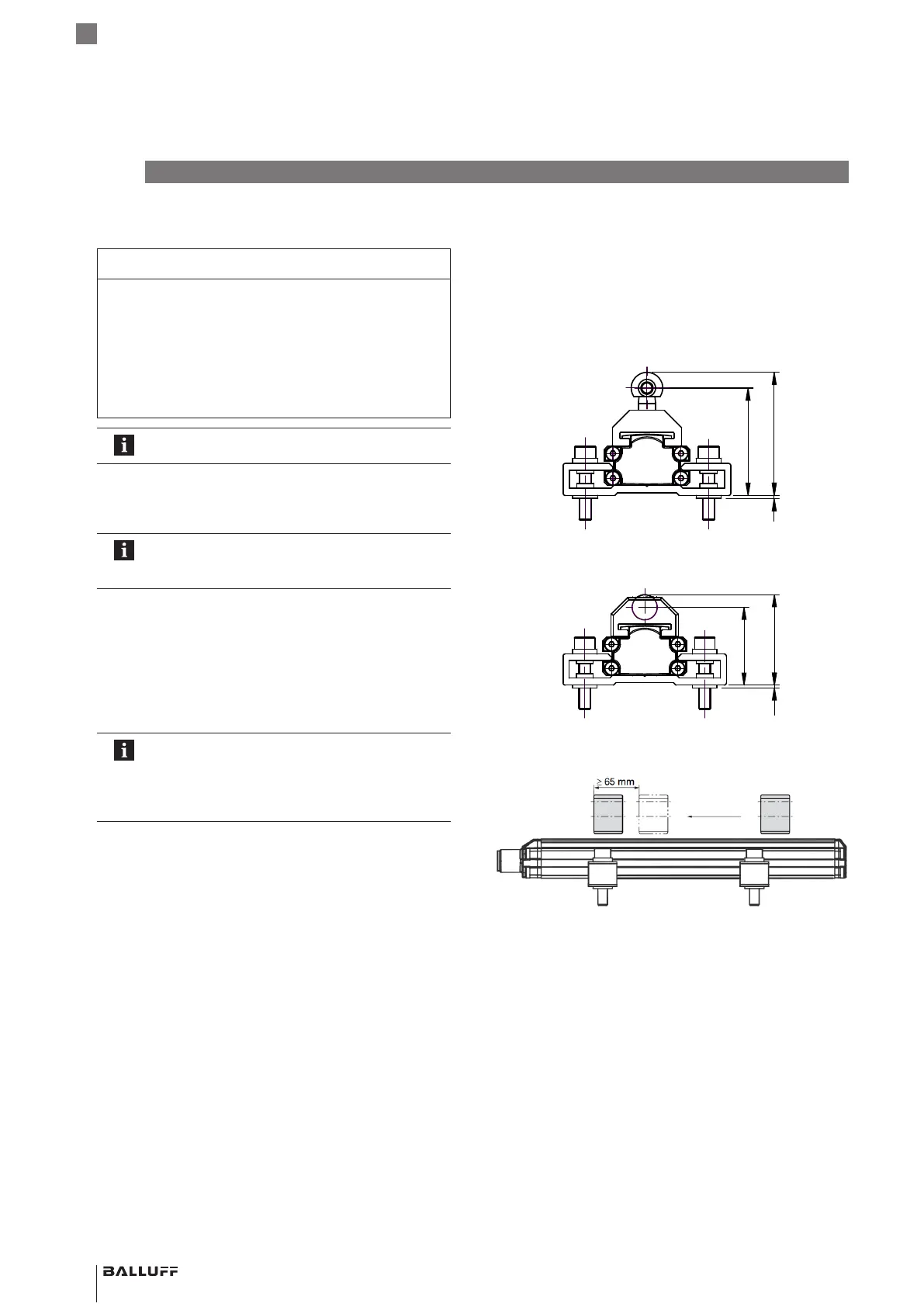

Fig. 5-2:

1

31.5

36.5

Dimensions and spacing with magnet BTL5-F-2814-1S

Fig. 5-3: Minimum spacing when using multiple magnets

BTL PF _ 400- _ _ _ _ -C12NL _ _ -0-000S04

Magnetostrictive Linear Position Sensor – Profile Style

Loading...

Loading...