www.balluff.com 11english

5

Installation and connection (continued)

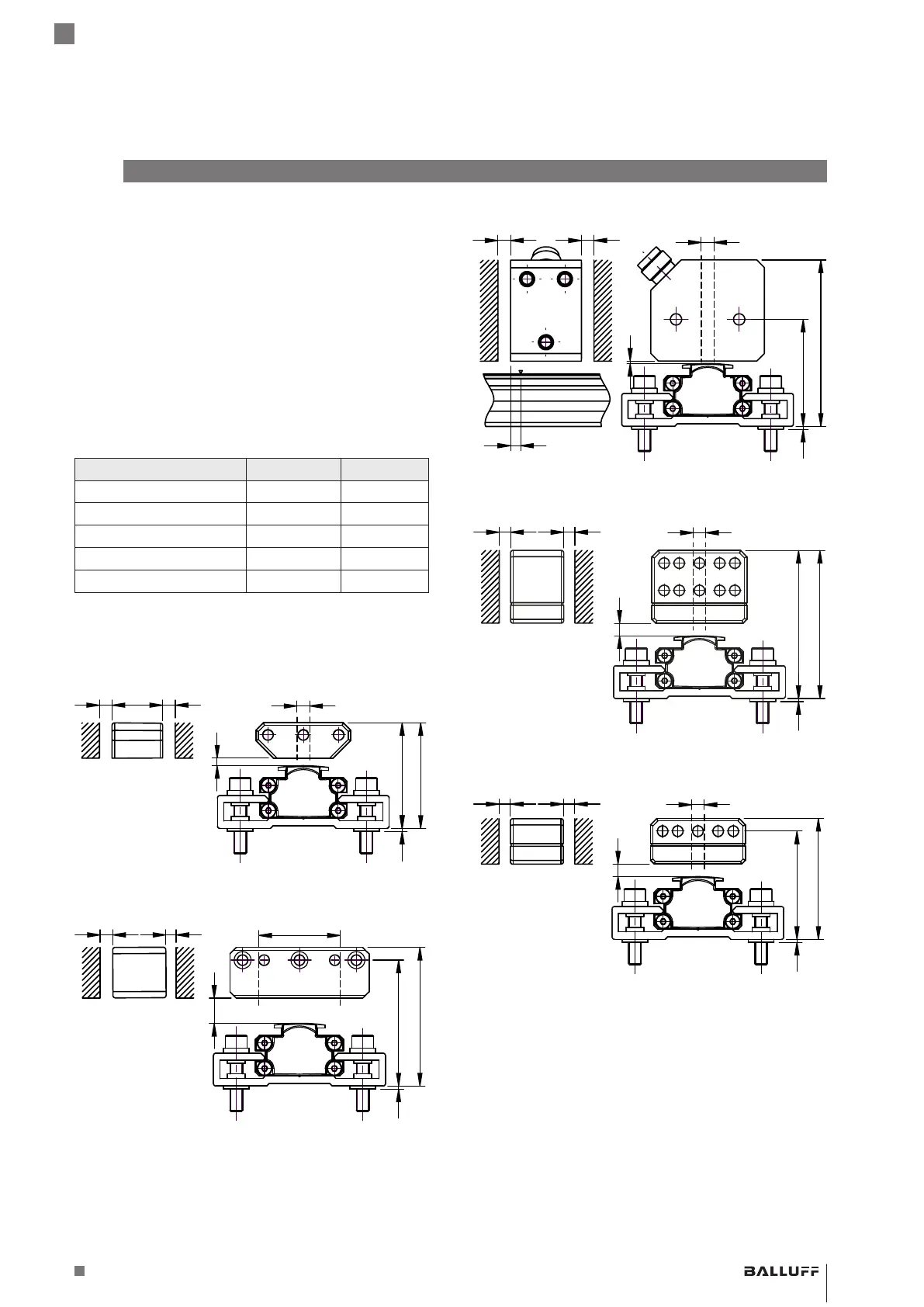

5.3 Floating magnets

Observe the following when installing the magnet:

– To ensure the accuracy of the magnetostrictive linear

position sensor, fasten the magnet to the moving

member of the machine only using non-magnetizable

screws (stainless steel, brass, aluminum).

– The moving member must guide the magnet on a

parallel line to the BTL.

– Distance A between the magnet and parts made of

magnetizable material must be kept to at least 10 mm

(see Fig. 5-4 to Fig. 5-8).

– For distance B between the magnet and the BTL and

for the center offset C (see Fig. 5-4 to Fig. 5-8) the

following values must be maintained:

Magnet type Distance B

1)

Offset C

BTL5-P-3800-2 0.1…4mm ±2mm

BTL5-P-5500-2 5…15mm ±15mm

BTL5-P-4500-1 0.1…2mm ±2mm

BTL6-A-3800-2 4…8mm

2)

±5mm

BTL6-A-3801-2 4…8mm

2)

±5mm

1)

The selected distance must remain constant over the entire measuring

length.

2)

For optimal measurement results: 6…8mm

Tab. 5-1: Distance and offset for magnets (see Fig. 5-4 to Fig. 5-8)

Fig. 5-4:

1

34+4

39+4

B

C

A A

Dimensions and spacing with magnet BTL5-P-3800-2

Fig. 5-5:

1

45+10

50+10

B

C

A A

Dimensions and spacing with magnet BTL5-P-5500-2

Fig. 5-6:

Plug with

LED

1

41.5+2

65+2

B

C

A A

4

Dimensions and spacing with magnet BTL5-P-4500-1

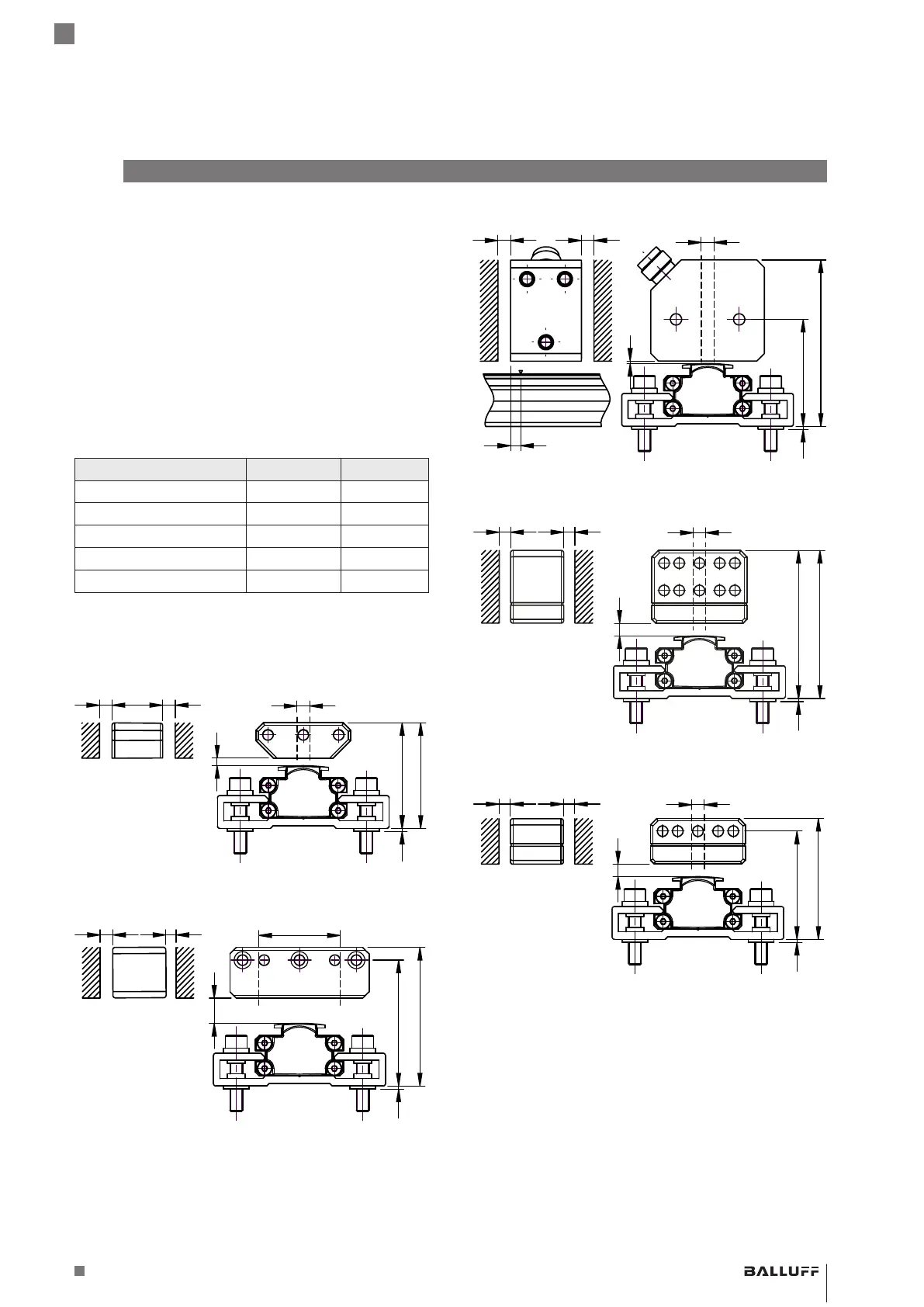

Fig. 5-7:

1

53+4

58+4

B

C

A A

Dimensions and spacing with magnet BTL6-A-3800-2

Fig. 5-8:

1

42+4

47+4

B

C

A A

Dimensions and spacing with magnet BTL6-A-3801-2

BTL PF _ 400- _ _ _ _ -C12NL _ _ -0-000S04

Magnetostrictive Linear Position Sensor – Profile Style

Loading...

Loading...