5.4 Sensor Mounting and Mechanical Alignment

Verify that:

• The emitter and receiver are directly opposite

each other

• Nothing is interrupting the

defined area

• The defined area is the same distance from a

common reference plane for each sensor

• The emitter and receiver are in the same plane

and are level/plumb and square to each other

(vertical, horizontal, or inclined at the same

angle, and not tilted front-to-back or side-to-

side)

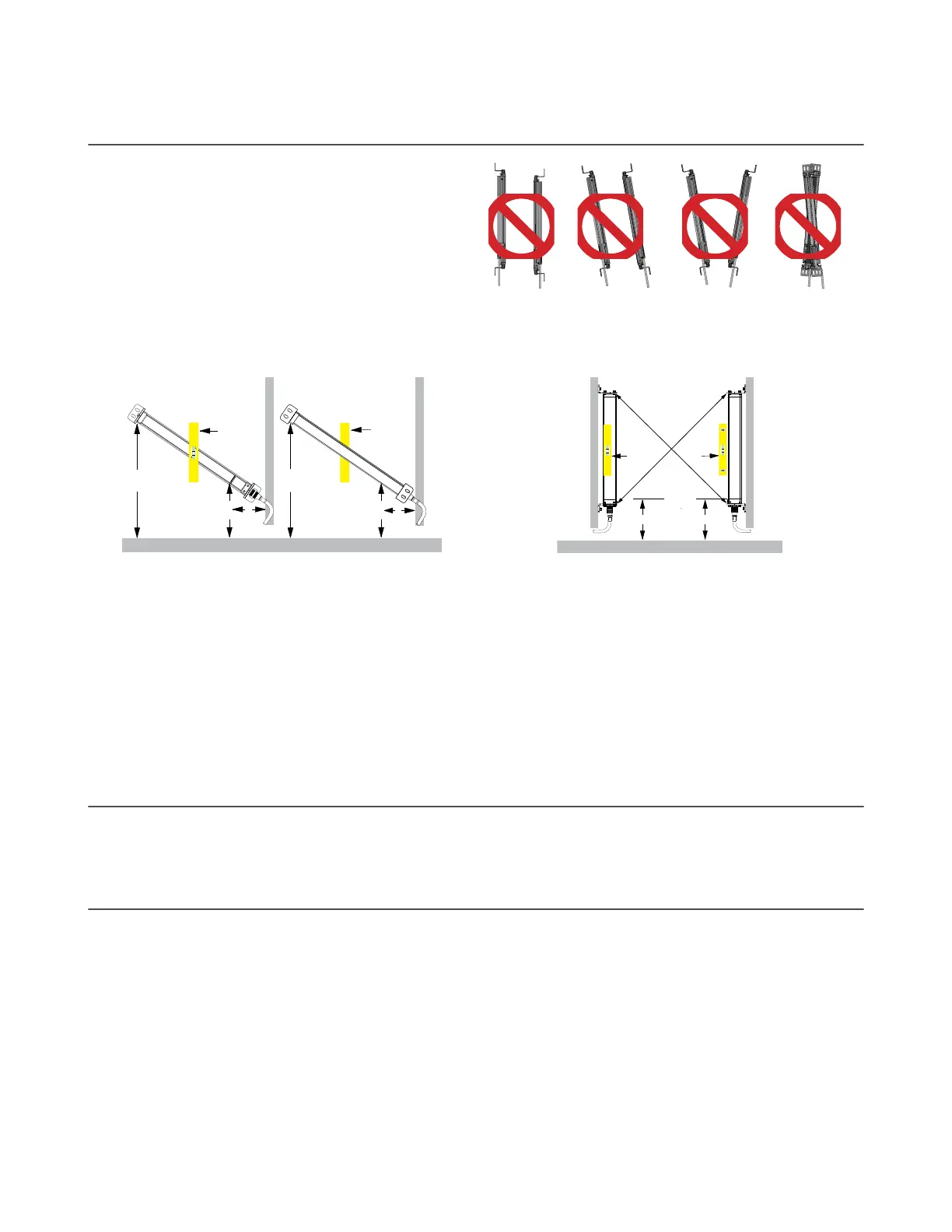

Figure 11. Incorrect Sensor Alignment

Level Surface

X X

Emitter Receiver

level

level

Y Y

Z

Z

Level Surface

A B

level level

XX

Angled or Horizontal Installations – verify that:

• Distance X at the emitter and receiver are equal

• Distance Y at the emitter and receiver are equal

• Distance Z at the emitter and receiver are equal from

parallel surfaces

• Vertical face (the window) is level/plumb

• Defined area is square. Check diagonal

measurements if possible; see Vertical Installations,

on the right.

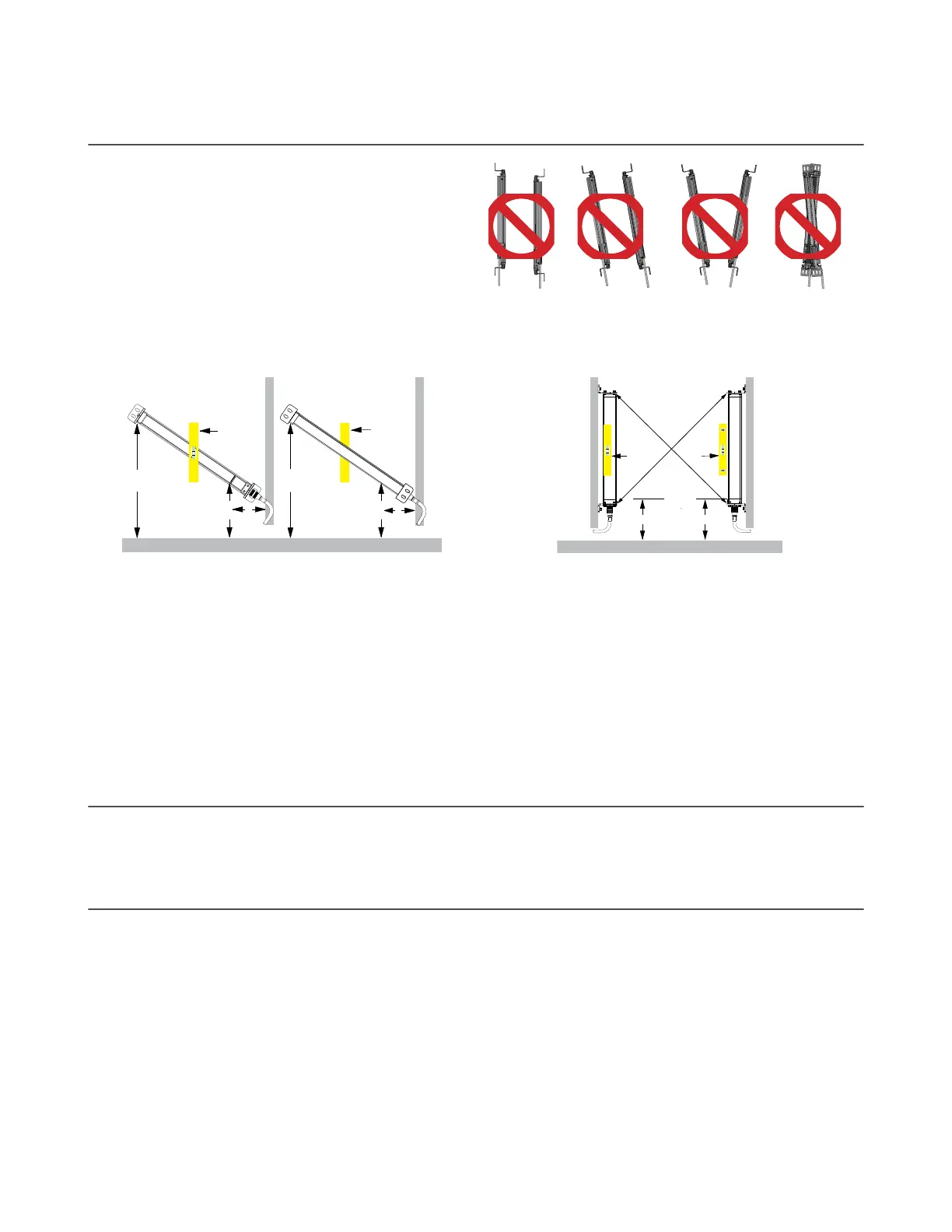

Vertical Installations – verify that:

• Distance X at the emitter and receiver are equal

• Both sensors are level/plumb (check both the side

and face)

• Defined area is square. Check diagonal

measurements if possible (Diagonal A = Diagonal B).

5.5 Mounting the Reset Switch

Mount the reset switch in a location that complies with the warning in

Reset Switch Location

on page 23. See

Initial

Electrical Connections

on page 31 for electrical connection.

5.6 Routing Cordsets

Attach the required cordsets to the sensors, and route the sensor cables to the junction box, electrical panel, or other

enclosure in which the interface module, the redundant mechanically linked interposing relays, FSDs, or other safety-related

parts of the control system are located. This must be done per local wiring code for low-voltage dc control cables and may

require installation of electrical conduit. See

Accessories

on page 88 for selection of Banner supplied cables.

EZ-SCREEN is designed and manufactured to be highly resistant to electrical noise and to operate reliably in industrial

settings. However, extreme electrical noise may cause a random Trip or Latch condition; in extreme cases, a Lockout is

possible.

Emitter and receiver wiring is low voltage; routing the sensor wires alongside power wires, motor/servo wires, or other high

voltage wiring may inject noise into the EZ-SCREEN System. It is good wiring practice, and sometimes may be required by

code, to isolate emitter and receiver cables from high-voltage wires, avoid routing cables close to “noisy” wiring, and

provide a good connection to earth ground.

Sensor cabling and any interconnect wiring should have an insulation temperature rating of at least 90 °C (194 °F). In

addition, QD cabling and any interconnect wires should meet the

specifications in the following table:

EZ-SCREEN

®

14/30 mm Safety Light Screen

30 www.bannerengineering.com - Tel: + 1 888 373 6767

Loading...

Loading...