A: PL120101.053

B: PL120100.053

E: 03.93 / T. Weiß

G: 06.93 / T. Weiß

Chapter: 5.3

Page: 2

?

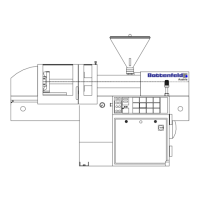

Structure and Function

Description of function:

The injection unit is set between the two closing cylinders by

means of the guiding rollers and the two nozzle drive cylinders.

The nozzle drive cylinders are directly connected to the

closing cylinders and have the form of double-action hydraulic

cylinders. The nozzle drive cylinders permit contact of nozzle

and mould as well as access to the nozzle when it is in the

rear end position.

The screw is driven by a slow-action hydraulic motor acting

directly on the injection cylinder piston via a toothed belt.

During the metering process, the injection piston also revolves;

this construction makes it possible to avoid rolling bearings

- which basically would be necessary for the thrust bearing of

the screw - since this function is supplied hydrostatically. At

the same time, the injection piston doubles as a screw

coupling.

The torque of the hydraulic motor can be adapted to the

requirements through selection of the appropriate hydraulic

pressure.

To extend the material life of the screw cylinder heater

bands, heat them regularly, beginning with the first day of

operation, and make sure that they are firmly anchored.

5.3.2 Nozzle change

Preconditions:

1. Eject residual material from screw cylinder.

2. Heat screw cylinder to last preset material temperature.

Process:

1. Pull back nozzle drive cylinder of injection unit to rear

limit stop.

2. Disconnect and dismount nozzle heater band.

3. Unscrew nozzle with suitable spanner.

4. Insert new nozzle; bear in mind that the thread must be

greased with heat-resistant material.

5. Screw in nozzle to limit but do not tighten yet.

6. Mount and connect nozzle heater band.

7. Tighten nozzle after heating to operating temperature.

5.3.3 Instructions for setting - nozzle centre

ATTENTION !

Loading...

Loading...