Structure and Function

A: PL120100.052

B: PL120100.052

E: 03.93 / T. Weiß

G: 03.93 / T. Weiß

Chapter: 5.2

Page: 3

?

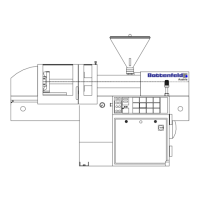

5.2.2 Mould fitting

The mould is inserted into the closing unit from above by

means of a suitable hoisting device. An eccentric ring (D=110

f7; 4,33 inch) is used to position the mould close to the nozzle

plate.

The unit may be fastened in three different ways:

1. Screw to platen with at least two diagonal threads per half

of mould (M12, torque 70 Nm; 95 ft lb).

2. Screw through platens by means of 4 head cap screws

M12x95 (torque 70 Nm; 95 ft lb), using the provided holes

(D=14; 0,55 inch).

3. Fasten by means of at least two clamping brackets per half

of mould; with the brackets arranged diagonally on each

platen.

5.2.3 Instructions for fitting - adjustment of fitting height

The minimum fitting height is preset at 150 mm (5,9 inch) in

the factory. The fitting height can, however, be adjusted by

means of the fastening nuts, thus permitting the full use of the

opening stroke. The height is adjusted in the following manner:

1. Mark the current nut position of the fastening nut (item 1)

with respect to the closing plate.

2. Remove (item 2) fastening nuts.

3. Unscrew back tightening nut (item 3) until end of piston rod

is reached.

4. Calculate necessary number of rotations for the fastening

nut. The thread pitch is 4 mm, from which the adjustment

stroke can be calculated as follows:

If the result is not an even number, round down to next even

Loading...

Loading...