Structure and Function

A: PL120000.055

B: PL120000.055

E: 06.93 / T. Weiß

G: 06.93 / T. Weiß

Chapter: 5.5

Page: 3

?

3) Processing of reclaimed material

The UNIFEED device is principally suited for feeding

regenerated material together with new granulated material.

However, the grain size must not exceed 3-4 mm (0.12-0.16

inch).

It must be said that a higher degree of contamination entails

increased clogging of the filter; thus it is imperative to clean the

device more frequently.

3) Maintenance

The secondary filter should be checked depending on the

quantity of dust gathered, but at least once per week, and

cleaned if necessary.

Its material life is limited; for this reason, it should be

exchanged (by simply pushing it out of the guiding device) at

the first sign of the fibres becoming loose.

The primary filter is automatically cleaned by compressed air

after each feed cycle. In case of heavy clogging, proceed as

follows:

1) Remove knurled nuts (Item 11);

2) Lift cover (Item 12);

3) Clean filter.

When installing the filter, make sure that the O-ring is

afterwards carefully reinserted in its correct position.

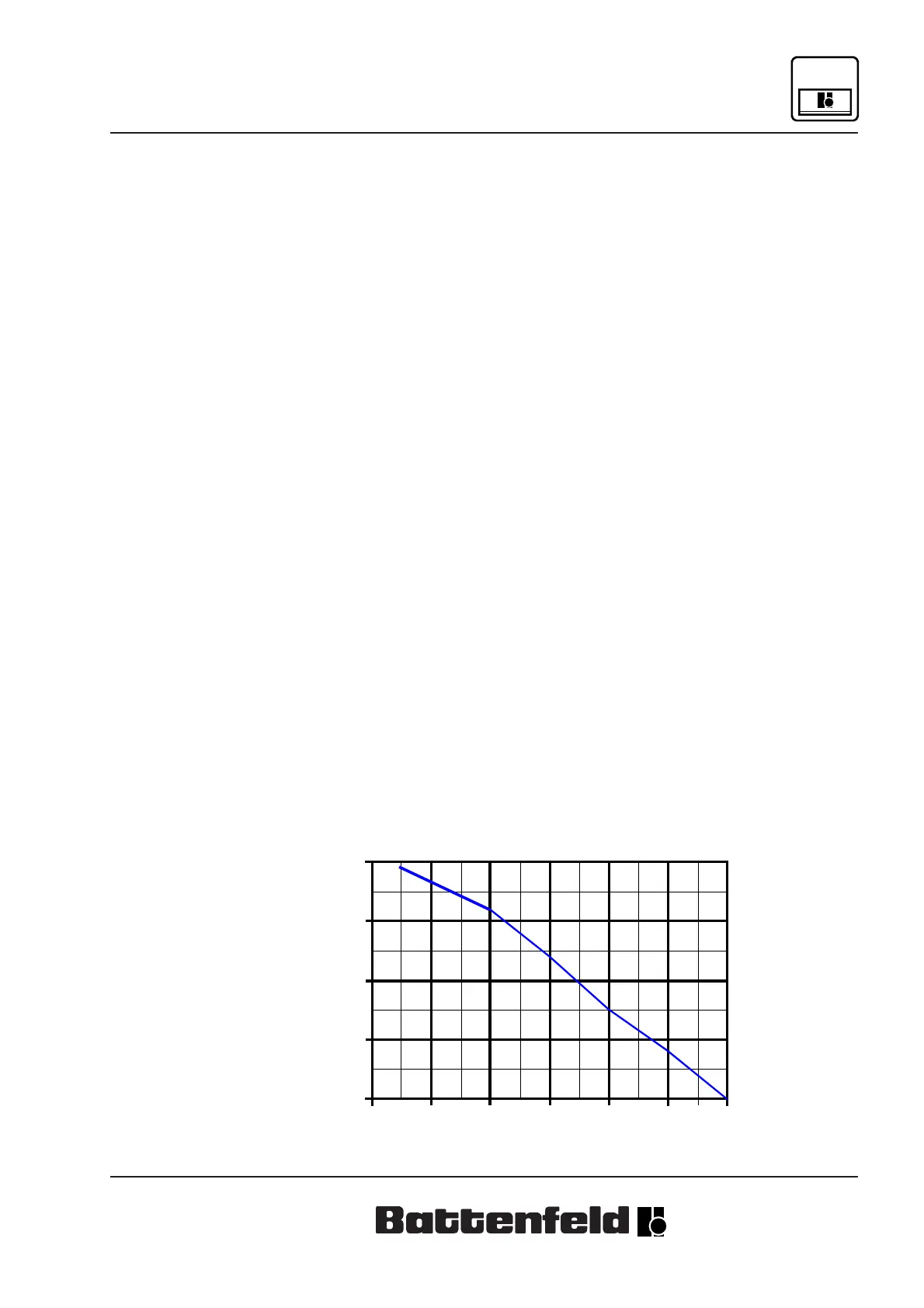

4) Material transporting capacity

With a pneumatic pressure of 6 bar (87 psi), full action time

(100%) and a tube with a nominal width of 19 mm (0.75 inch),

of which 4 m (13 ft) are laid vertically:

10 20 30 40 50 600

Bild: PL-0033.WMF

100

150

200

250

50

(112)

(225)

(338)

(450)

(562)

(112) (112) (112) (112) (112) 60

Length of tube

m

(ft)

Transport capacity PA

kg / h

(lb / h)

ATTENTION !

Loading...

Loading...