HB-37420-810-01-25F-EN SMX100 Installation manual.docx Page 237 of 260

Version: 25F

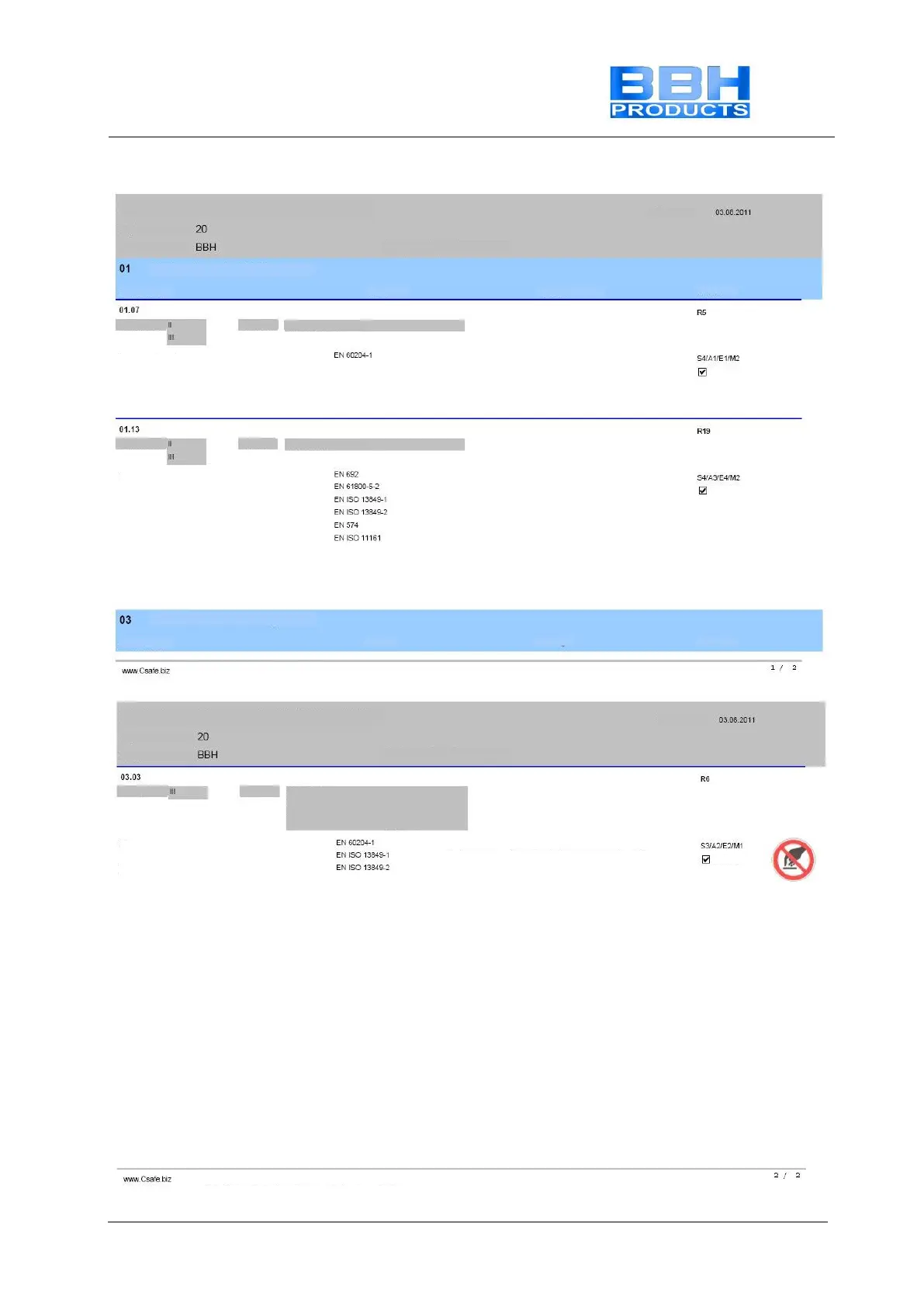

Example for a risk assessment:

When inserting the workpiece, the press cushion must be

moved. The hand is thereby in the press. The press itself is

active thereby and can move.

A closure of the press is impending while the hand and the

arm are in the tool.

Beim Verlust der Energieversorgung (Stromausfall) droht das

Absinken des Krafterzeugers. Falls sich in diesem Moment

der Werker in der Presse befindet, droht das Absenken des

Krafterzeugers auf den Werker.

With an energy loss, the safety valves enter the safe state

and a press movement is no longer possible.

The press can only be moved with safely reduced speed

(SLS). A safety-oriented joystick is used for this. when the

joystick button is released,

the standstill is monitored (SOS). The tool can only be closed

when the hand is removed from the tool and the two-hand

control is triggered. If the condition of safely reduced speed

of > 10m/s or standstill is infringed, the safety valves are

released via the safety chain and the press goes into the safe

state. The safety control SMX of BBH guarantees in SIL3 that

standstill and safely reduced speed are enabled in a safety-

oriented manner.

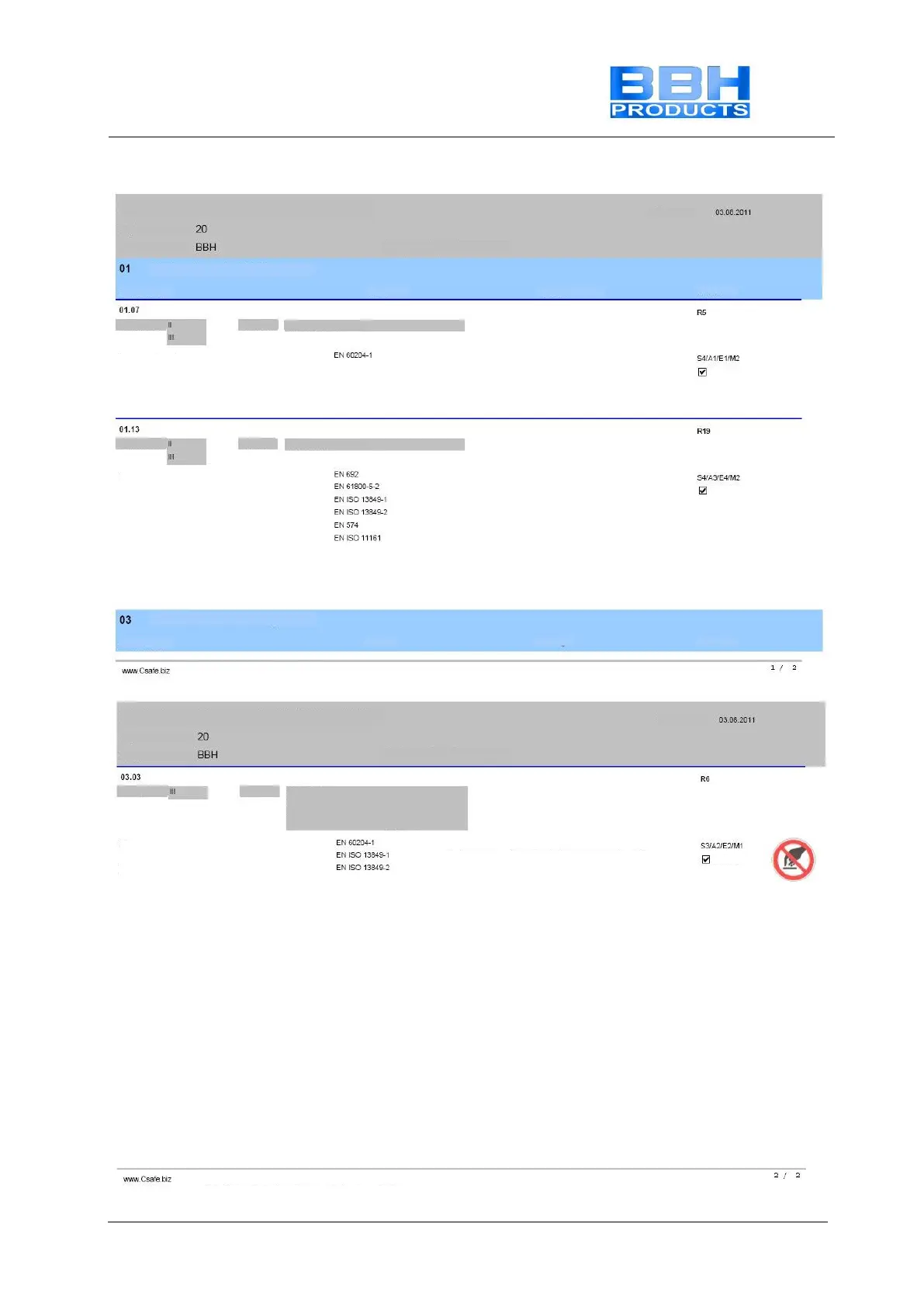

The preheating tool for the foaming system is brought to a

temperature of 120°. Contact or a temperature rise is

impending in the event of an error.

The temperature of the preheating unit is monitored so that a

dangerous temperature cannot be reached.

Additionally, a warning signs warns about conact. In normal

operation, the temperature does not increase so much that a

significant endangerment occurs.

The temperature is monitored via secure analog input and a

heat sensor, so that, in the event of an error, the preheating

unit is switched off and is protected from restarting.

Transformation transfer press

With the loss of the power supply (power failure),

drop of the power generator is impending. If

the operator is in the press at this moment, lowering

of the power generator on the worker is impending.

Life phase I=Transport II=Assembly III=Operation IV=Disposal

Risk assessment acc. to EN 12100:2010

Risk assessment acc. to EN 12100:2010

Transformation transfer press

Insertion operation

Conversion

Cleaning and keeping clean

Error search and error correction

Objects or materials of high or low Tem

Life phase I=Transport II=Assembly III=Operation IV=Disposal

Loading...

Loading...