3.6.4

Power and Motor Connection

31

3 - RECEIVING AND INSTALLATION

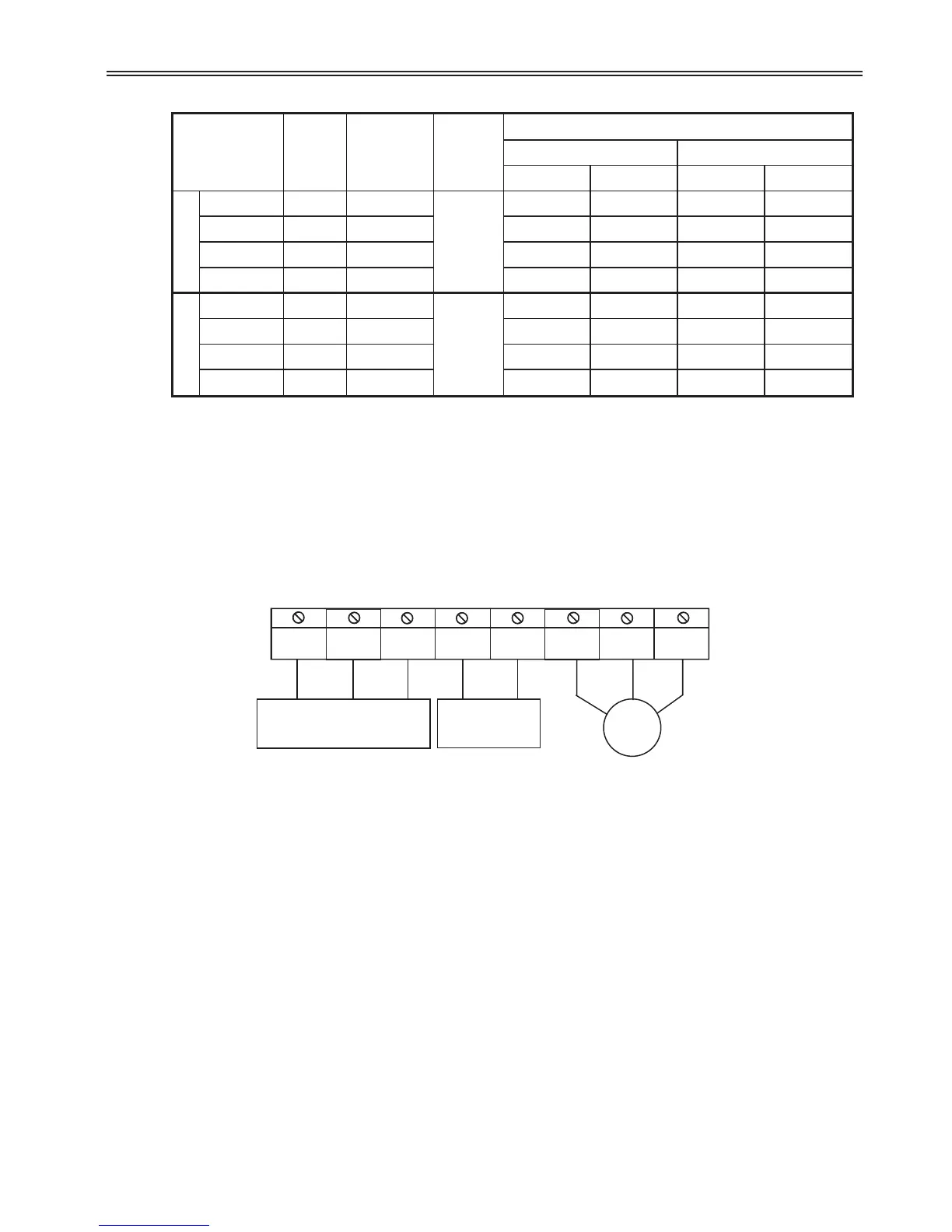

Drive Capacity

Terminal

Screw

Size

Screw

Torque

1)

Kgfcm /

lb-in

Grounding

Method

Wire

2)

mm

2

AWG

R,S,T U,V,W R,S,T U,V,W

2

0

0

V

1.0HP M3 10/8.7

Type 3

2 2 14 14

2.0HP M3 10/8.7 2 2 14 14

3.0HP M3 15/13 2 2 14 14

5.0HP M3 15/13 3.5 3.5 12 12

4

0

0

V

1.0HP M3 10/8.7

Special

Type 3

2 2 14 14

2.0HP M3 15/13 2 2 14 14

3.0HP M3 15/13 2 2 14 14

5.0HP M3 15/13 2 2 14 14

1) Apply the rated torque to terminal screws. Loose terminal screws can cause a short circuit or

other malfunction. Over tightening the terminal screws/bolts may permanently damage the

terminals.

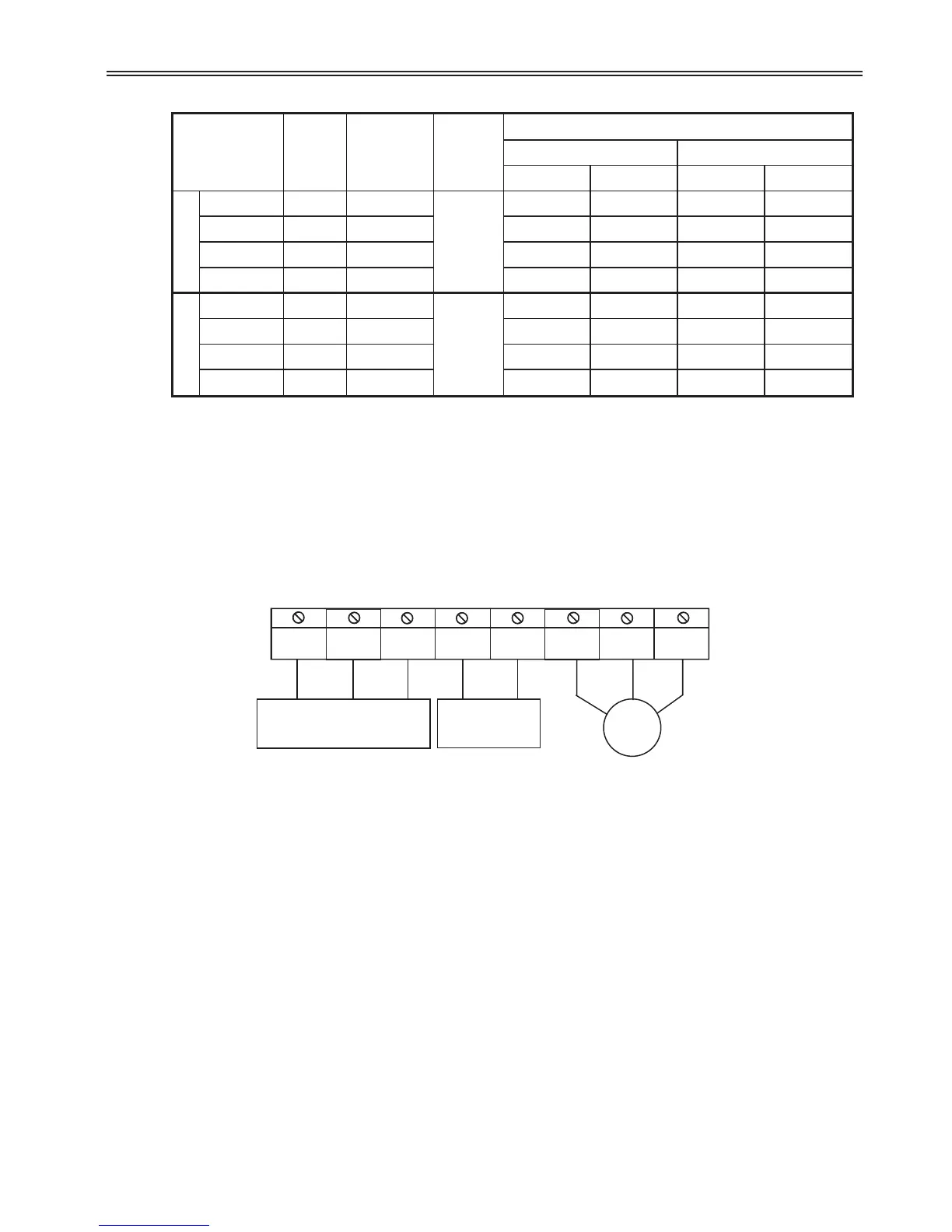

Motor should be connected to the

U,V,W terminals.

If the forward swich (FX) is on, the

motor should rotate counter clockwise

when viewed rom the load side of the

motor. If the mtor rotates in the reverse

direction, switch the U and V terminals.

Power supply must be connected o

the R,ST terminals.

Connecting it to the U,V,W terminals

causes internal damages to the drive

Arrangng the phase sequence is not

necessary.

R

S

T

B1

B2

U

V

W

DB

Resistor

3 Power Input: R,S,T

1 Power Input: R,T

f

f

Loading...

Loading...