Density Meter LB 444 SECTION 3. INSTALLATION

27

3.2

Installation

Installation on Pipelines

The radiation exit channel of the shielding container must always be

locked in the closed position during installation.

The detector must be protected against temperatures

>

50°C by a water-

cooling jacket.

The cables must be protected against temperatures

>

70°.

When selecting the installation site, please keep the following criteria in mind:

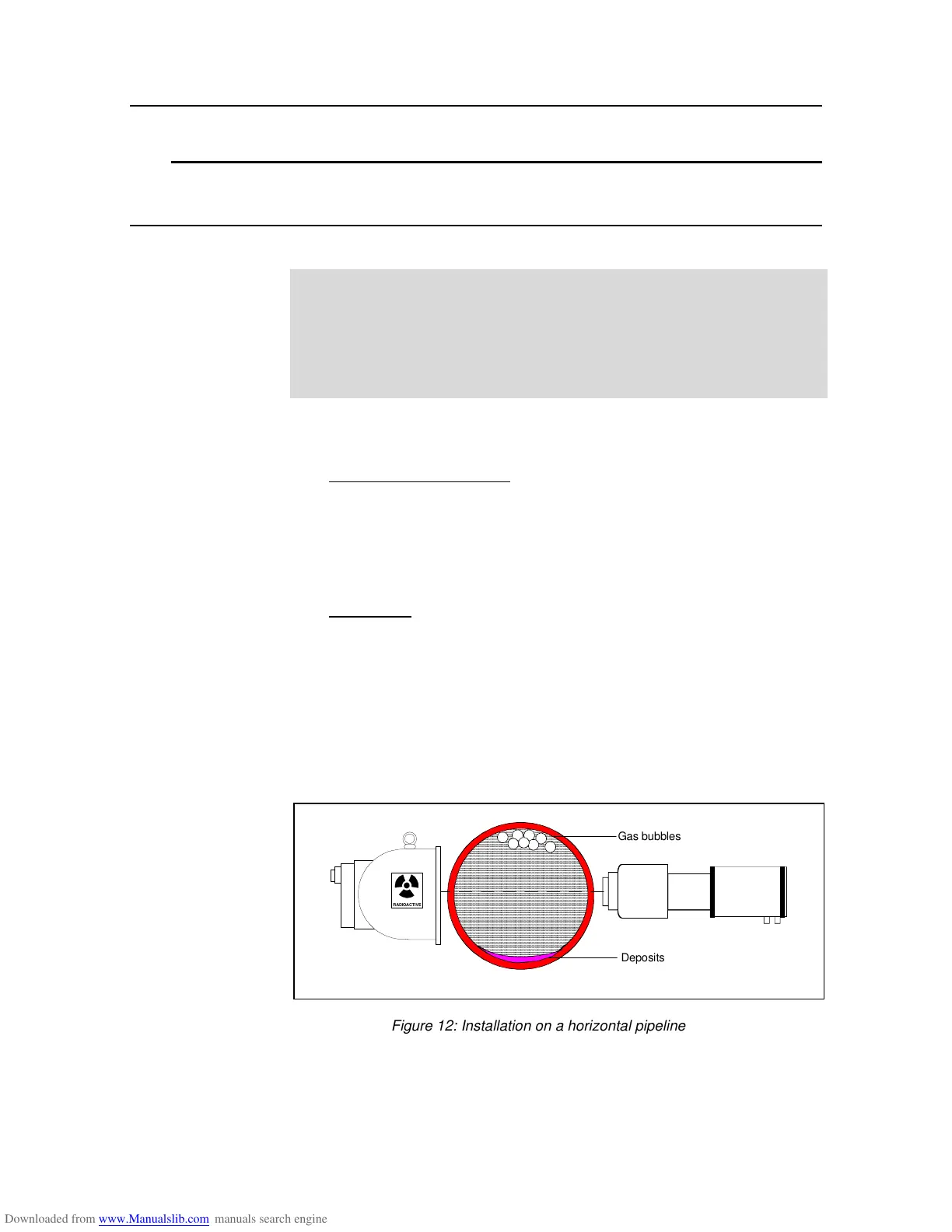

a) Selection of measuring site. At the measuring point, the pipeline must al-

ways be completely filled with the product being measured. If the pipeline is

only partially filled, this may result in incorrect measurements.

b) Corrosion, abrasions or deposits on the pipeline walls will result in incorrect

measurements.

This problem is minimized with installations on vertical pipes.

c) Gas bubbles in the product falsify the results. This error can be avoided or

at least reduced by installing the measurement system at a point on the

pipeline where the pressure is fairly high (e.g. installation in pressure pipes,

at the foot of a standpipe).

d) If no air bubbles are to be expected in the product, the suction side of a

pump should preferably be used for installation to exclude air bubbles

which might occur as a result of aging pump seals.

e) Measurements on horizontal pipelines should be performed with horizontal

irradiation to reduce errors caused by deposit formation and gas bubbles.

Loading...

Loading...