C (E3) 08/2015 page 77/93

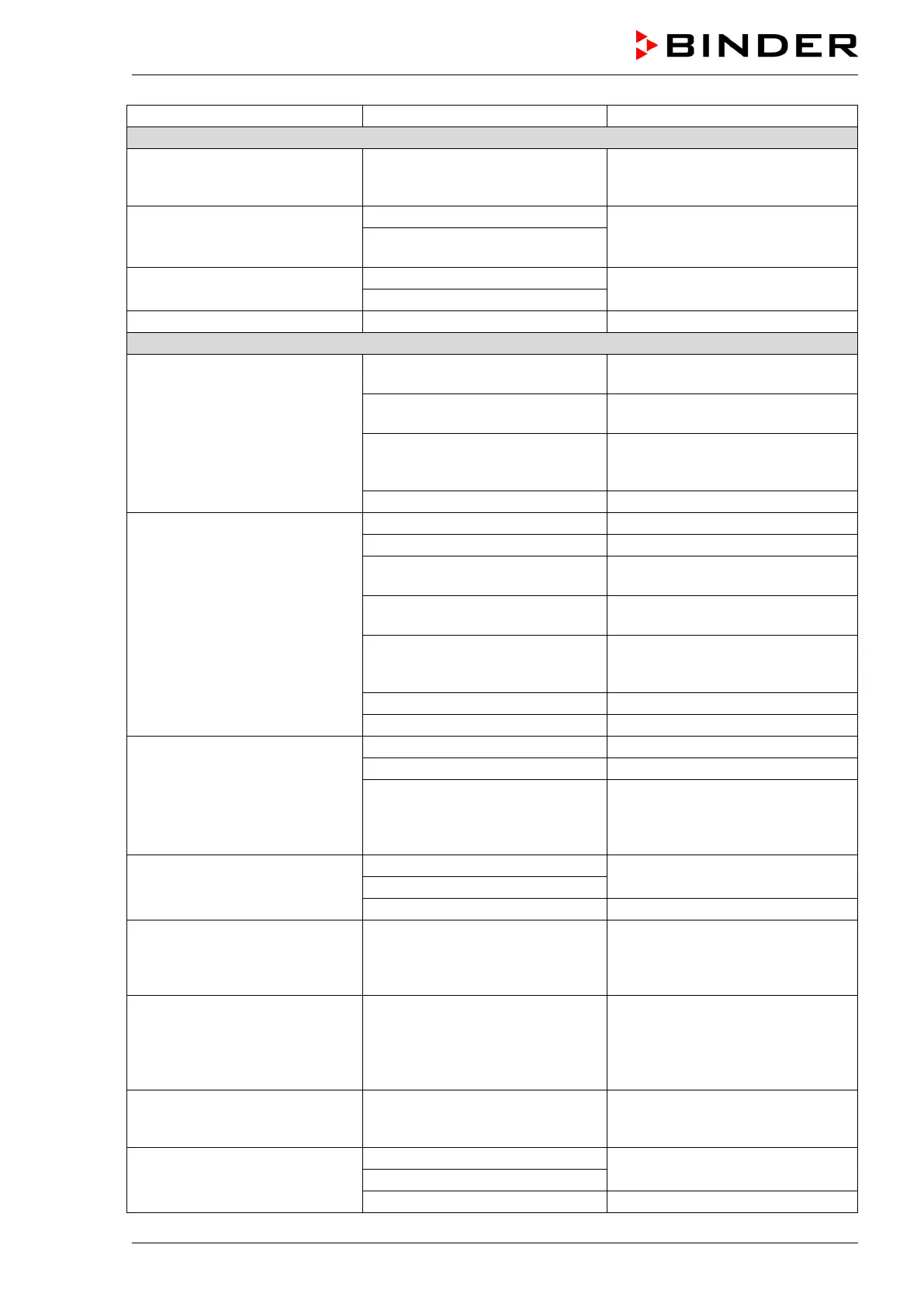

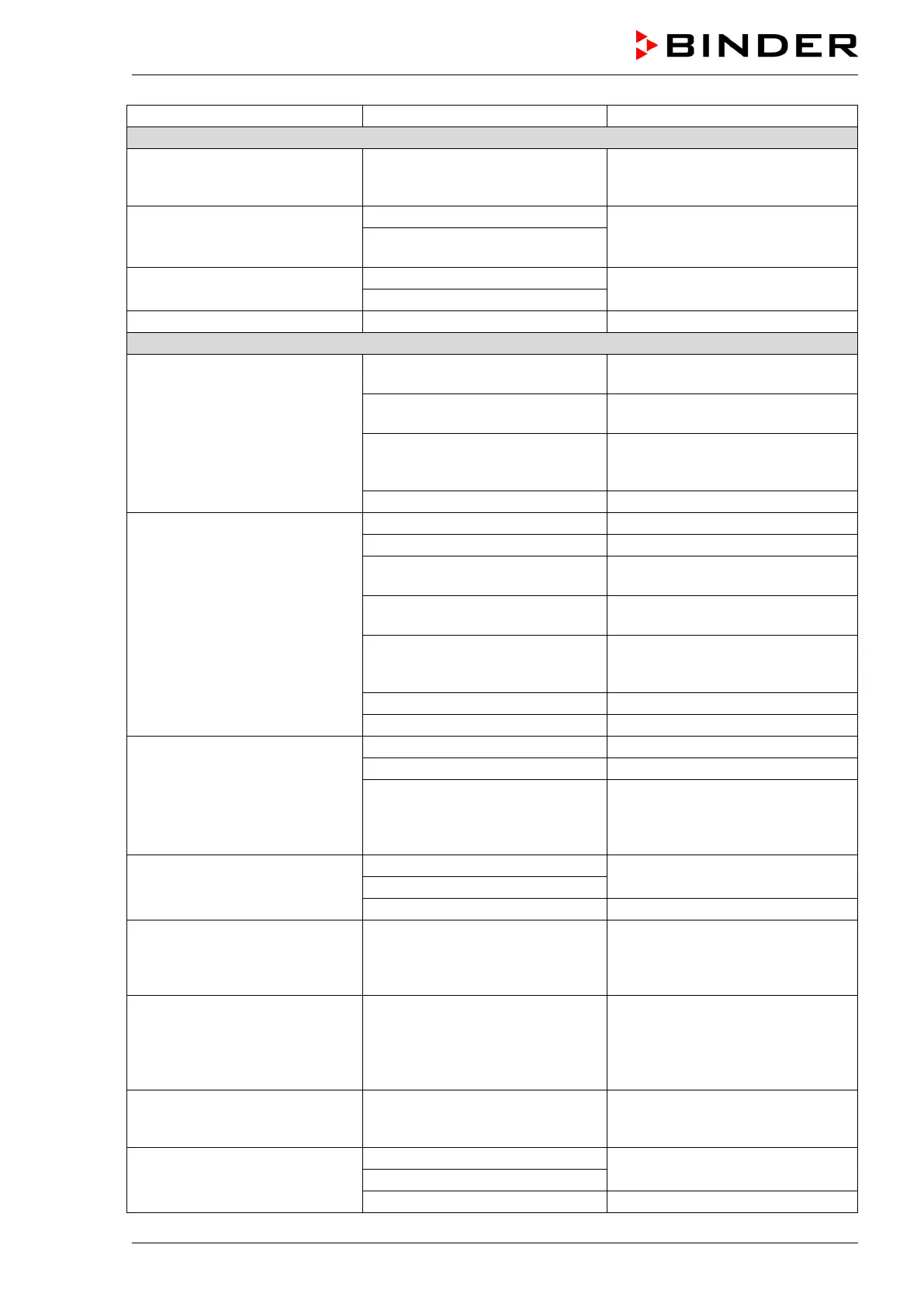

Temperature inside too low.

Message “otc” is displayed

(safety controller alarm).

Limit temperature reached. Safe-

ty controller (chap. 9.2) set too

Check the setting of the safety

controller. Choose a suitable limit

Temperature inside too high.

Message “otc” is displayed

(safety controller alarm).

Contact BINDER service.

Safety controller (chap. 9.2) de-

fective.

Chamber heating permanently,

set point not held.

Semiconductor relay defective.

Contact BINDER service.

Message “End” is displayed

Sterilization cycle completed.

Start up the unit (chap. 5).

Pressure alarm. Message “P.Lo”

is displayed (low pressure

alarm).

2

cylinder is not connected

correctly.

Correctly connect the gas cylinder.

Connected gas cylinder is closed

or empty.

Open or replace gas cylinder.

Gas hose is dirty or obstructed.

Check the tube system for dirt

accumulation or obstruction, clean

Pressure sensor system defective

CO

2

concentration inside too low

(controller display).

2

cylinder is not connected

correctly.

Correctly connect the gas cylinder.

Connected gas cylinder is closed

or empty.

Open or replace gas cylinder.

Gas hose is dirty or obstructed.

Check the tube system for dirt

accumulation or obstruction, clean

Calibrate and adjust controller

CO

2

concentration inside too low

(controller display). Message

“con” is displayed (CO

2

toler-

ance range alarm)

Wrong controller setting.

Check and, if appropriate, set the

operating function “AL.2” (CO

2

alarm threshold) (chap.

7.3). Value

should be ≥ 1.0 vol.-%.CO

2

.

CO

2

concentration inside too

high (controller display).

Contact BINDER service.

Calibrate and adjust controller

2

high (controller display). Mes-

sage “con” is displayed (CO

2

Wrong controller setting.

Check and, if appropriate, set the

operating function “AL.2” (CO

2

alarm threshold) (chap.

7.3). Value

should be ≥ 1.0 vol.-%.CO

2

.

2

largely compared with a refer-

ence method.

The pH indicator of the cell me-

dium changes its normal color

CO

2

sensor system defective.

Transfer the cultures to another

incubator and contact BINDER

Service.

Recovery time (up to 5 vol.-%

CO

2

) after doors were open for 2

minutes is < 2 minutes.

CO

2

sensor system defective. Contact BINDER service.

Recovery time (up to 5 vol.-%

CO

2

) after doors were open for 2

minutes is > 10 minutes.

Check gas supply (cylinder, con-

nections, hose system).

Insufficient CO

2

input pressure.

Gas fine filter obstructed.

Loading...

Loading...