97

Údržba stroje

Wartung

External Leakages

Contamination

Damages

Noise-(level)

Gauges

•

•

•

•

-

-

-

•

-

-

-

-

-

-

•

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

4.7. Machine cleaning

Clean the machine off cooling agent and impurities after every shift. Conserve the

guiding surfaces, mainly.

Guiding of the clamping jaws of the main and feeder vice.

Guiding of the feeder.

The loading surface of the main and feeder vice

Thread rod of the main and feeder vice

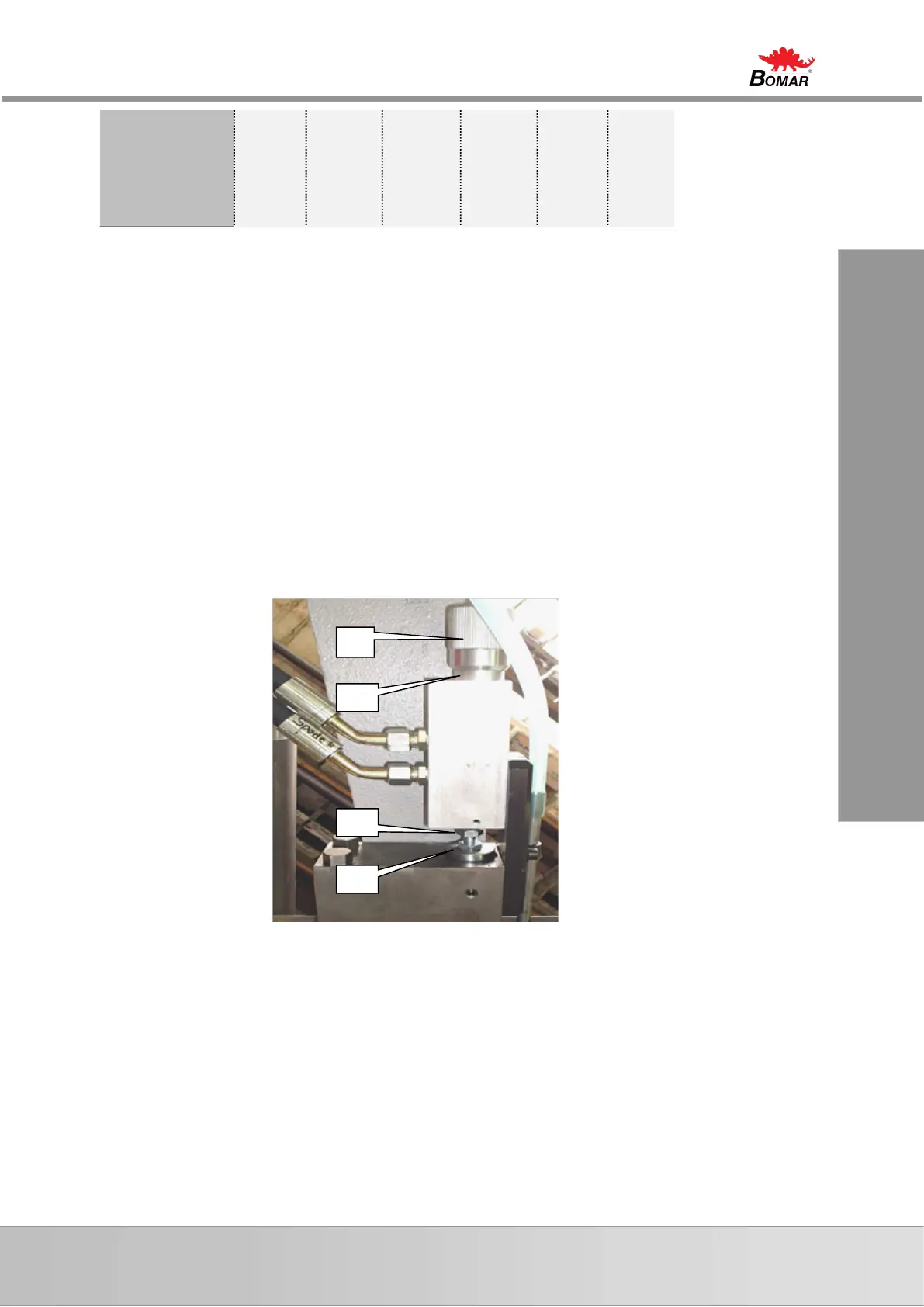

4.8. Adjustment of the regulating pressure to the cut

Device for regulation of the pressure to the cut is primarily set by the manufacturer.

Do not manipulate with adjustment of the device if you do not have serious reason!

Adjustment procedure:

1. Set the body of the regulation by adjusting handle. It is under the handle. Set

it on the second groove. There is visible one neck (pos. 1, 2).

2. Screw the stopper screw to the maximum, or the valve will be blocked (pos. 3)

3. Now the frame can be freely moved up only, because the saw frame

movement is blocked with the governing valve

4. Press button „ saw frame down „ screw on the setscrew

5. Screw in the stop screw as long as you reach the optimal speed of the frame

sinking

6. Optimal speed of the frame sinking is between 40-50 sec.from max.lift.

Loading...

Loading...