24/68 Transport and storage

Bosch Rexroth AG, A20V(L)O Series 1, RE 93100-01-B/2019-09-10

6.1.2 Transport with lifting devices

For transporting, theaxial piston unit can beconnected toalifting device via aneye

bolt inthe drive shaft orinthe housing. Alternatively, itcan also betransported

with alifting strap. When selecting the means of transport, consider the permissible

totalweight.

Only use thelifting strap ifyou are unable toachieve therequired installation

position with transport using theeye bolts.

The axial piston unit can betransported suspended from aneye bolt screwed into

thedrive shaft aslong asonly outward (pulling) axial forces are applied.

▶ For all female threads, use astud end from thesame system ofunits and

ofthecorrect size.

▶ To do this, screw aneye bolt completely into thefemale thread onthe drive shaft.

The thread size isindicated inthe installation drawing.

▶ Make sure that theeye bolt can bear thetotal weight oftheaxial piston unit

plus20%.

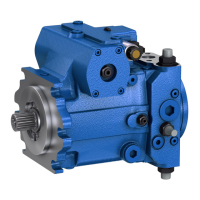

You can lift theaxial piston unit asshown inFig. 5 with theeye bolt screwed into

thedrive shaft.

Fig. 5: Mounting theeye bolt inthe drive shaft

▶ For all female threads, use astud end from thesame system ofunits and

ofthecorrect size.

▶ Screw the eye bolts completely into the female threads in the housing.

▶ Make sure that the eye bolts can bear the total weight of the axial piston unit plus

approx. 20%.

You can hoist theaxial piston unit asshown inFig. 6 with theeye bolts screwed into

thehousing.

Transporting with

eyebolt in drive shaft

(only permissible for

sizes 60 to 260)

Transport with eye

bolt inhousing

(only possible for

sizes 190 to 520)

Loading...

Loading...