38/68 Installation

Bosch Rexroth AG, A20V(L)O Series 1, RE 93100-01-B/2019-09-10

• Ifashared drain line isused for several units, make sure that therespective case

pressure ineach unit isnot exceeded. The shared drain line must bedimensioned

toensure that the maximum permissible case pressure ofall connected units

isnot exceeded inany operating conditions, particularly atcold start. If this isnot

possible, separate drain line must belaid, ifnecessary.

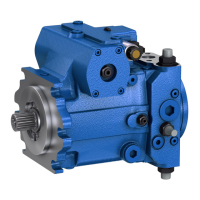

The type ofinstallation for theaxial piston unit depends onthe connecting elements

tothe drive side. The following descriptions explain theinstallation oftheaxial

piston unit:

• With acoupling

• On agearbox

• On acardan shaft

7.4.4 Installation with acoupling

The following describes how toinstall theaxial piston unit with acoupling:

NOTICE! Danger from improper handling!

Product can bedamaged!

▶ Do not install thecoupling hub onthe drive shaft oftheaxial piston unit

bystriking it.

1. Install thespecified coupling half onthe drive shaft oftheaxial piston unit

according tothe instructions ofthecoupling manufacturer.

The drive shaft oftheaxial piston unit isequipped with afemale thread. Use this

female thread topull thecoupling element onto thedrive shaft. The size

ofthefemale thread can beseen inthe installation drawing.

2. Clamp thecoupling hub onto thedrive shaft orensure permanent lubrication

ofthedrive shaft. This prevents theformation offrictional corrosion and

theassociated wear.

3. Transport theaxial piston unit tothe installation location.

4. Remove dirt and foreign particles from theinstallation location.

5. Install thecoupling onthe output shaft ofthedrive motor inaccordance with

thespecifications provided bythecoupling manufacturer.

Do not fasten down theaxial piston unit until thecoupling has been correctly

installed.

6. Fasten theaxial piston unit attheinstallation location.

7. Align thedrive shaft oftheaxial piston unit and theoutput shaft ofthedrive

motor sothere isno angular deviation.

8. Make sure noexcessive axial and radial forces are acting onthe drive shaft.

9. For bell housing installation, check thecoupling axial play through thebell

window according tothe manufacturer's specifications.

10. Details onthe required tools and tightening torques for themounting bolts are

available from themachine/system manufacturer.

11. When using elastic couplings, check that thedrive does not resonate after

completing theinstallation.

Loading...

Loading...