11 Troubleshooting

11.1 Troubleshooting procedure

As a matter of principle, the instructions in the project planning and commis-

sioning manuals must be followed in case of failures and errors. Contact the

manufacturer, if necessary.

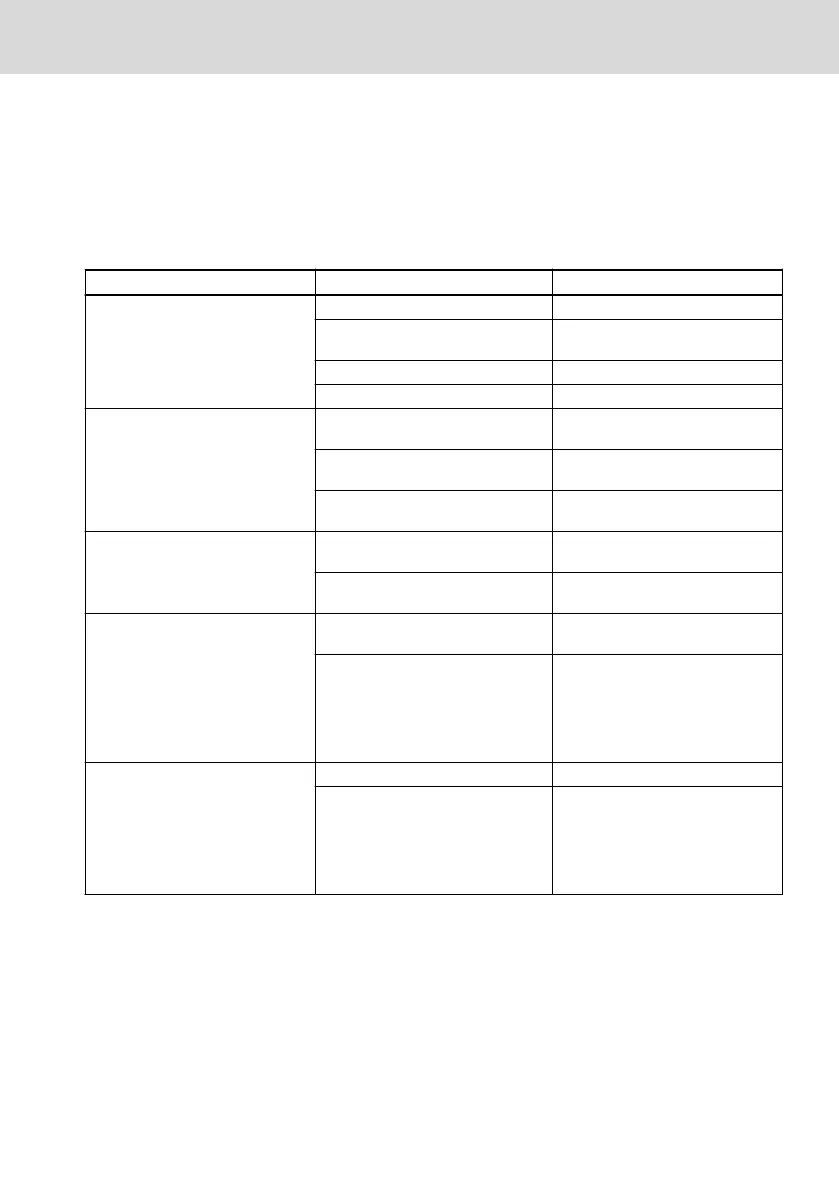

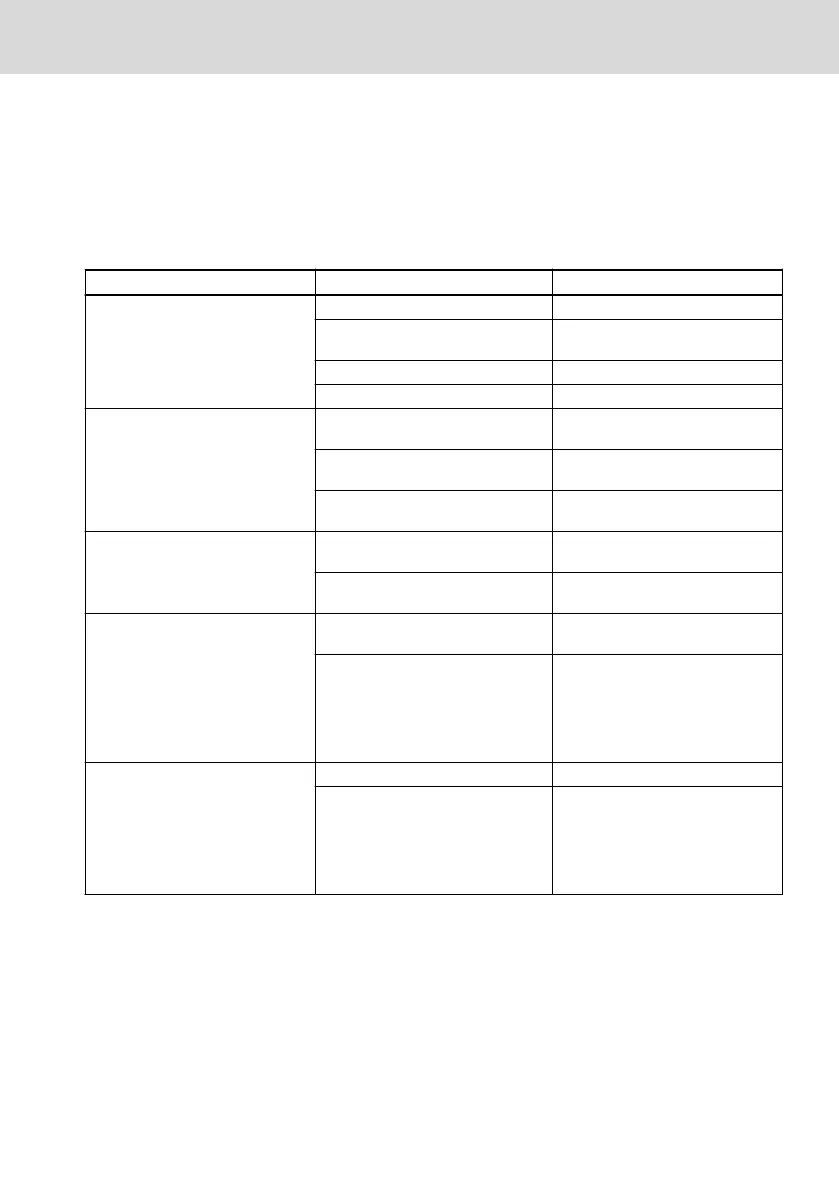

Malfunctions Error cause Measures

Motor does not run Controller enable signal missing Activate controller enable signal

Controller fault Troubleshoot acc. to documentation

of controller

Voltage supply missing Control voltage supply

Brake is not released Check the brake activation

Vibrations Coupling elements or attachments are

poorly balanced

Re-balance

Adjustment of shaft end attachments

(coupling, gearbox, ...) is insufficient

Re-align the attachments

Mounting screws loose Lock screw connections acc. to spec-

ifications

Running noise Foreign bodies within the motor Stop the motor --> repair by manu-

facturer

Bearing is damaged Stop the motor --> repair by manu-

facturer

High motor temperatures

Motor temperature monitoring is ac-

tivated

Operation outside of rated data Reduce load and check the dimen-

sioning

Heat dissipation is impaired Clean the motor

For fan units, clean fan grille and

check the fan function

For liquid cooling, check cooling cir-

cuit.

Wrong or defective temperature dis-

play

Temperature sensor not connected Connect temperature sensor

Temperature sensor defective Stop the motor --> repair by manu-

facturer

Replace temperature sensor

Connect the backup temperature

sensor, if any is available.

Tab. 11-1: Measures in case of malfunctions

MS2N Synchronous Servomotors

93/101

Troubleshooting

R911347581_Edition 04 Bosch Rexroth AG

Loading...

Loading...