● If provided by the manufacturer, all lifting eye bolts must be used and tight-

ened before use.

● Avoid increased transport vibrations.

● Remove any existing transport locks prior to commissioning and keep them.

5.5 Bearing

Store the motors in their original packaging in a dry, dust-free, vibration-free and

light-protected place without direct solar radiation. Please observe classes

1K21, 1B1, 1C1, 1S10, 1M11 specified for storage acc. to DIN EN 60721-3-1.

Please observe the following classification limitations:

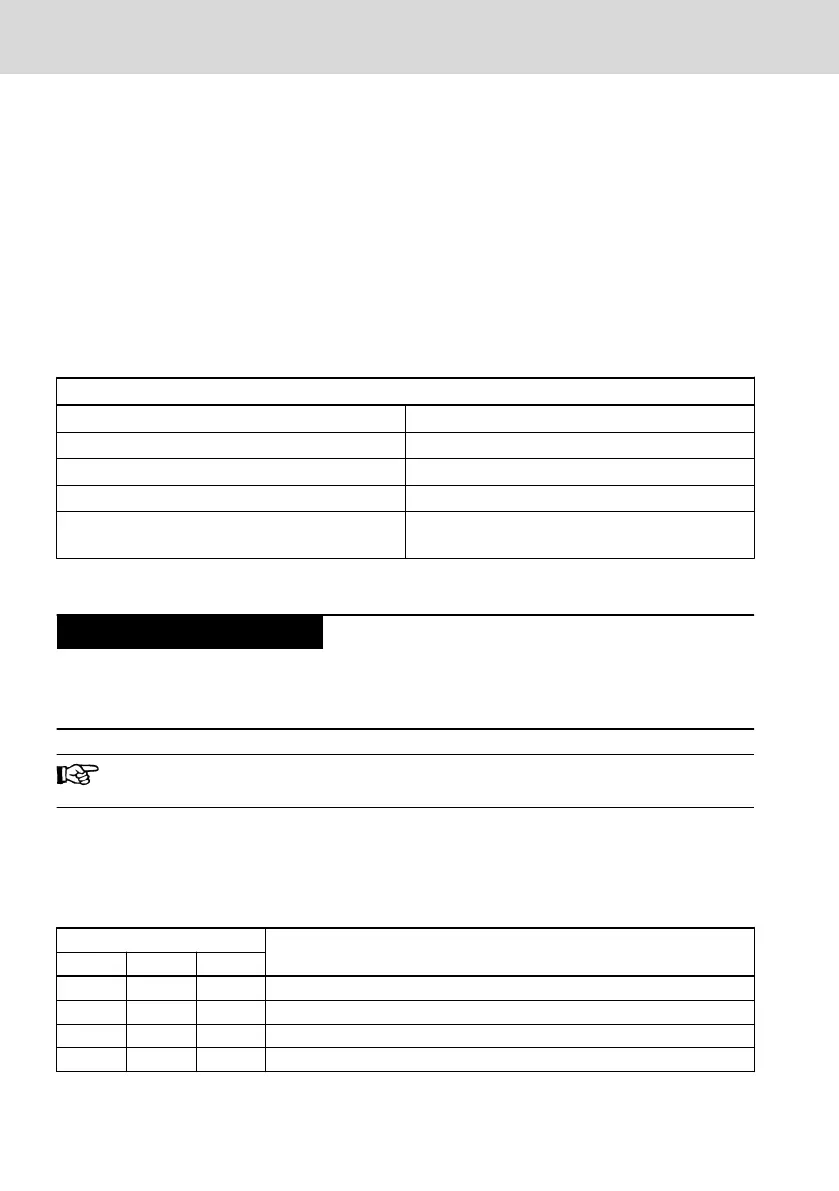

Bearing

Ambient temperature -25 … +55 °C

Relative air humidity 5 … 75 %

Absolute air humidity 1 … 29 g/m³

Direct solar radiation Not permitted

Shock load

Refer to section shock load during transport und

storage

Tab. 5-7: Classification limitation (DIN EN IEC 60721-3-1)

Damage due to moisture and humidity!

● Protect the products from dampness and corrosion.

● Store them only in rainproof and dry rooms.

Before storage, discharge the liquid coolant from liquid-cooled mo-

tors to avoid frost damage.

Additional measures have to taken upon commissioning to ensure smooth

functioning - irrespective of the storage time which may be longer than the

warranty period of our products. Warranty extension is not a consequence.

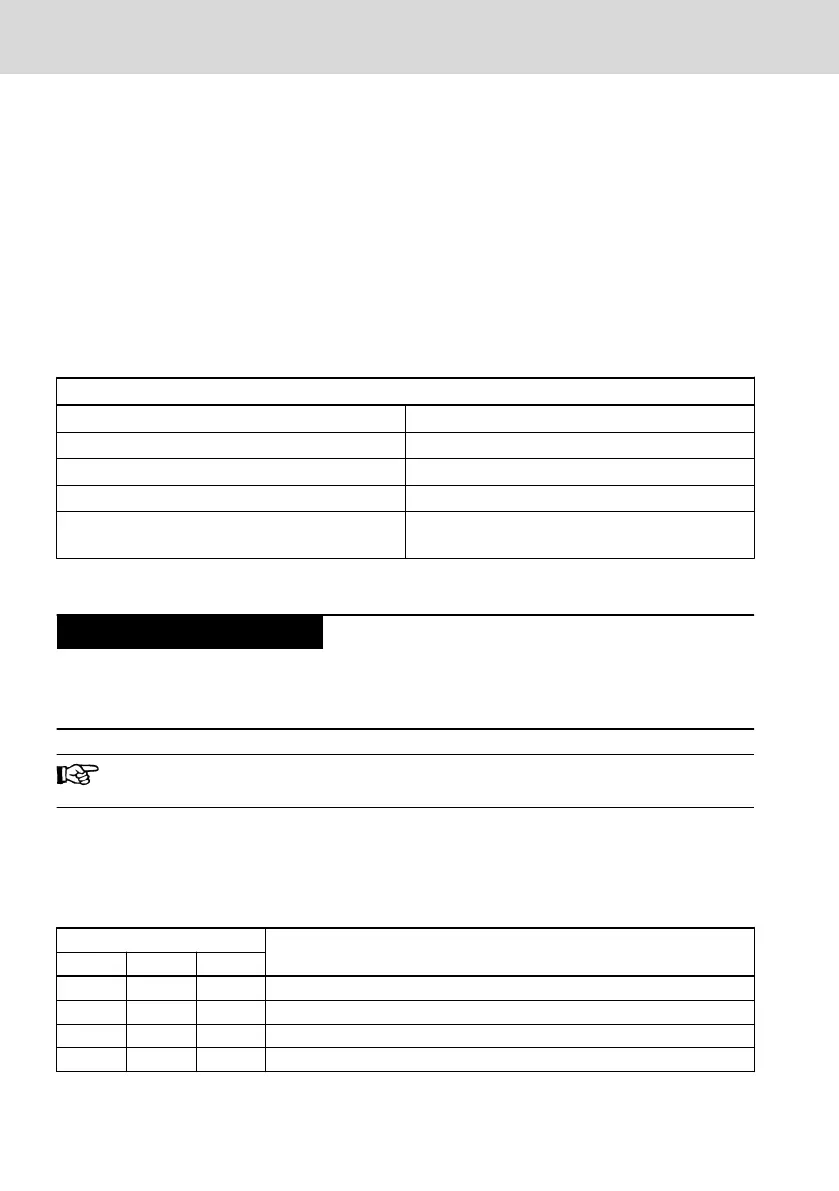

Motors

Storage time/months

Measures for commissioning

> 1 > 12 > 60

● ● ● Visual inspection of all parts to be damage-free

● ● ● Resurface the holding brake

● ● Check the electric contacts to verify that they are free from corrosion

● ● Let the motor run in without load for one hour at 800 ... 1000 rpm.

46/101

Operating conditions and handling

MS2N Synchronous Servomotors

Bosch Rexroth AG R911347581_Edition 04

Loading...

Loading...