Bearing service life

The bearing lifetime is an important criterion for the availability of motors. The

operating conditions influence the bearing service life L

10h

considerably.

The following boundary conditions apply to the bearing service life L

10h

:

● Operation within the specified permissible loads (radial and axial force)

● Operation within the permissible ambient conditions (temperature range

0 … 40 °C, vibration, ... )

● Operation within the thermally permissible operating characteristic curve

The bearing lifetime also depends on the service life of the grease. A calculated

grease service life was used for the mentioned specifications, taking into consid-

eration the following boundary conditions.

● Horizontal installation

● Low vibration and impact loads

● No oscillating bearing movement < 180°

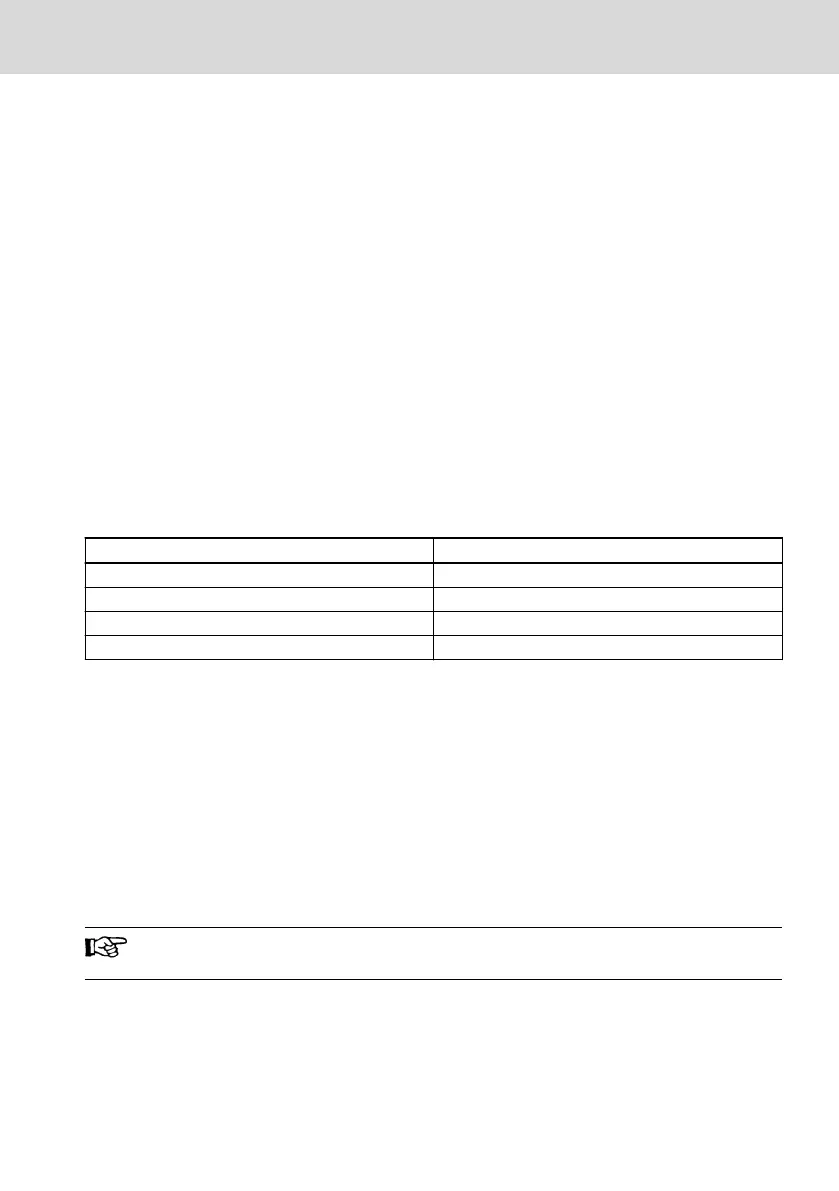

● Mean speed according to Table 4-14:

Type Mean speed

MS2N03, -04, -05, -06 ≤ 3500 1/min

MS2N07 ≤ 3000 1/min

MS2N10 ≤ 2000 1/min

MS2N13 ≤ 1800 1/min

Tab. 4-14: Mean speed - basis of calculated grease service life

The following standard values apply under the specified preconditions for the

60K and 100 K operation modes:

L

10h

in case of operation after S1-60K

L

10h

= 30.000 h, in case of utilization after S1-60K and max. load factor 95% dur-

ing the runtime.

L

10h

in case of operation after S1-100K

L

10h

= 20.000 h, in case of utilization after S1-100K and max. load factor 90%

during the runtime.

When exceeding or not complying with these conditions, a reduced

service life is to be expected.

Explanation of radial and axial force

During operation, both radial and axial forces act upon the motor shaft and the

motor bearing. The permissible radial force F

R

in distance x from the shaft shoul-

der and the mean speed is specified in the radial force diagrams.

MS2N Synchronous Servomotors

33/101

About this product

R911347581_Edition 04 Bosch Rexroth AG

Loading...

Loading...