In the case of other used coolants than water (e.g. oil), a perform-

ance reduction of the motor can be necessary to dissipate the cre-

ated power loss.

Motor damage due to missing or incompatible

coolant water!

● For this reason, water cooled motors may only be operated as long as coolant

supply is ensured.

● Do not use any cooling lubricants or cutting materials from machining pro-

cesses for cooling.

● Using aggressive coolant additives or additives can lead to irreparable motor

damage.

The dimensioning of the cooling system is in the responsibility of the

machine manufacturer.

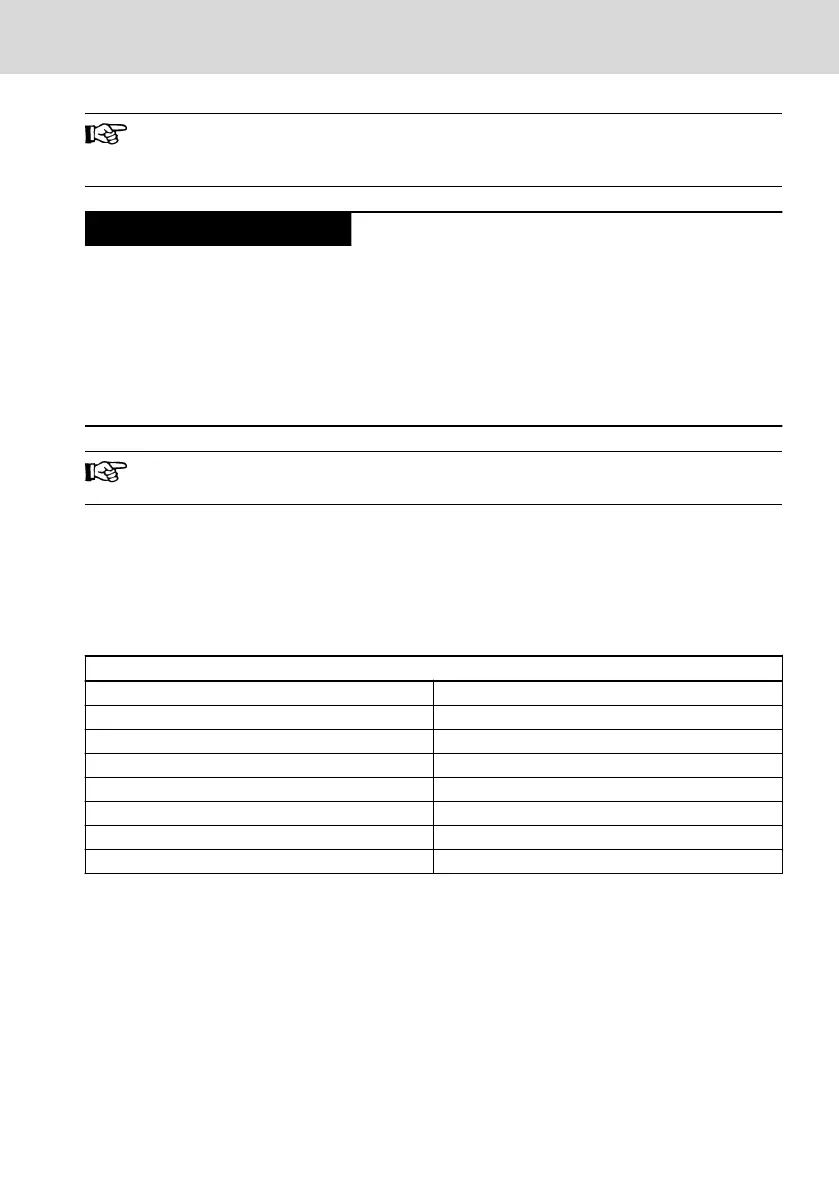

Coolant characteristics

Adjust the required coolant, especially the material compatibility must be speci-

fied with the manufacturer of the cooling unit and the manufacturer of the cool-

ant additives. The basic minimum requirements for the coolant are displayed in

the following.

Cooling water quality for motors with internal cooling circuit made of stainless steel.

pH value (bei 20 °C) 6 ... 9

Total hardness 1.2 ... 2.5 mmol/l

Chloride concentration < 150 ppm

Sulfate concentration < 200 ppm

Nitrate concentration < 50 ppm

Amount solutes < 350 ppm

Particle size of dirt ≤ 100 µm

Conductivity < 2000 µS/cm

Tab. 4-4: Coolant characteristics

Coolant temperature

When setting the coolant inlet temperature within a range of 10 ... 40°C (for de-

rating see chapter 5.2 "De-rating in case of deviating ambient conditions." on

page 41) observe the ambient temperature and the existing relative air humidi-

ty. To avoid condensation, the coolant inlet temperature must be above the dew

point temperature . The following figure shows the dependency of dew point

temperature of relative air humidity and air temperature.

MS2N Synchronous Servomotors

17/101

About this product

R911347581_Edition 04 Bosch Rexroth AG

Loading...

Loading...