5-4 ©2013 Brooks Automation Inc. Pub. No. 8040444, Rev. AA, 01/14/2013 ECO No. 63723

Adjusting System Helium Pressure

NOTE: These procedures can be performed on a compressor that is turned

ON or OFF. However, the helium pressure gauge should be set to the

("OFF" Condition) helium charge pressure value if the compressor is

turned OFF or set to the normal system operating pressure if the

compressor is turned ON. Refer to “Section 4 - Operation” for more

information.

Reducing Helium Pressure

NOTE: You must obtain the normal system operating pressure from the

“Compressor Operation” procedure in “Section 4 - Operation” in order to

perform this procedure. If the normal system operating pressure is

unknown, then shut the compressor OFF and perform the “"OFF"

Condition Helium System Pressure Verification” procedure in “Section 4 -

Operation” instead.

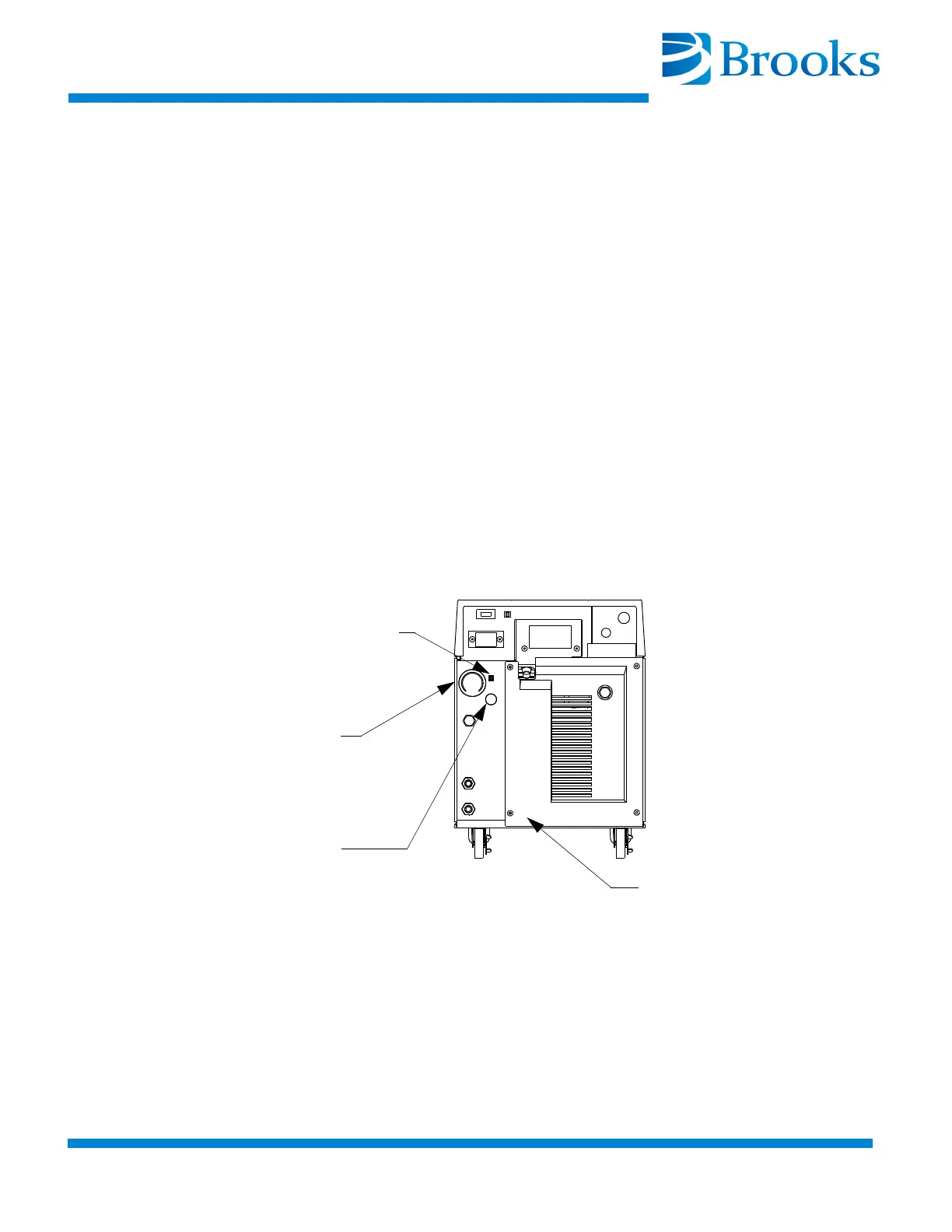

1. Remove the flare cap from the gas charge fitting as shown in

Figure 5-3.

Figure 5-3: Helium Pressure Control Components

2. Open the gas charge control valve very slowly to allow a slight

amount of helium to escape. Leave the valve open until the helium

pressure gauge indicates one of the following:

• To the appropriate value in Table 4-1 if the compressor is OFF and

acclimated to a temperature between 60º F and 80º F

(15.5º C - 26.6º C).

Gas Charge Flared Fitting

Helium

Pressure

Gauge

Rear Panel

Gas Charge

Control Valve

Loading...

Loading...