Specifications and Site Preparation Polycold Cryochiller

Cooling Water Installation and Operation Manual

Brooks Automation

3-8

214072 Revision B

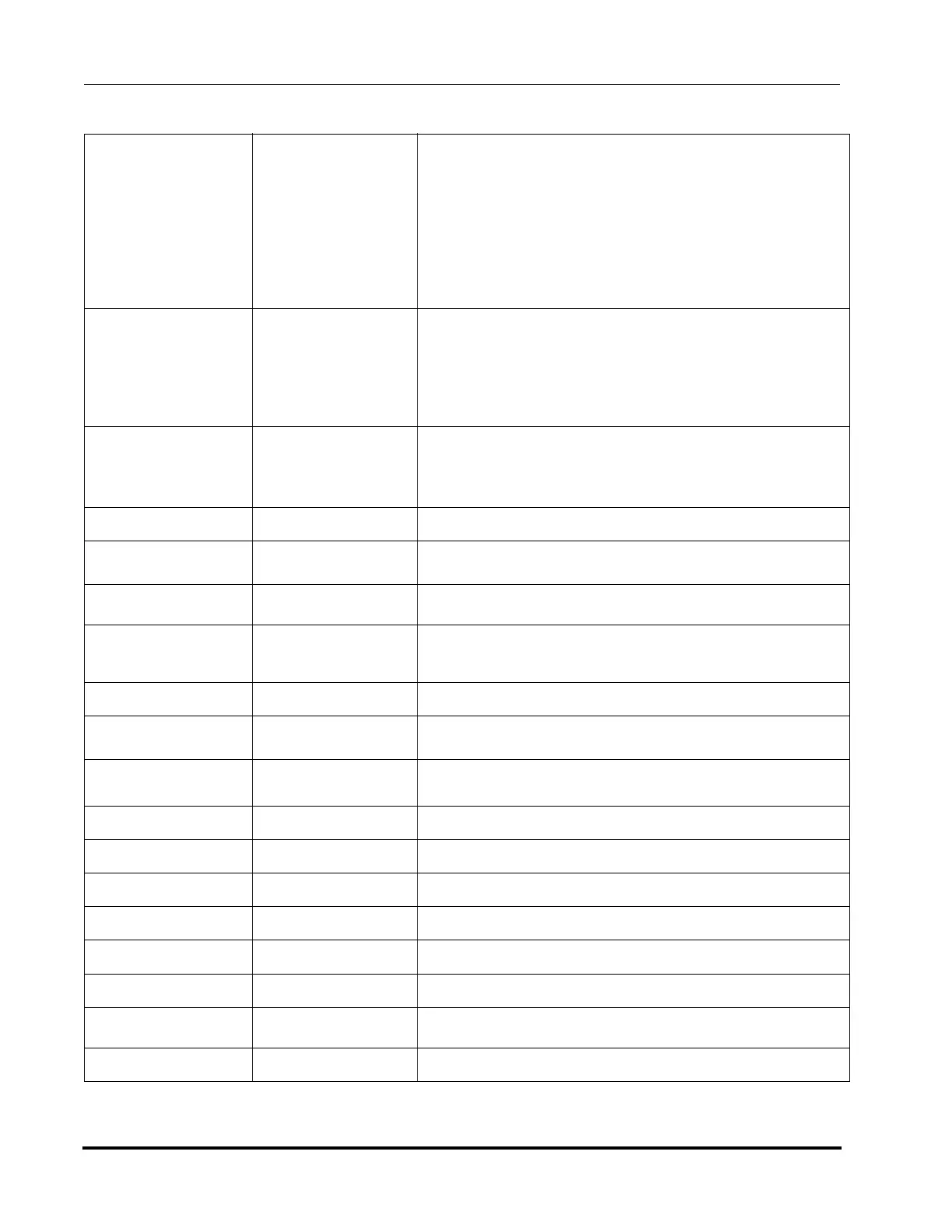

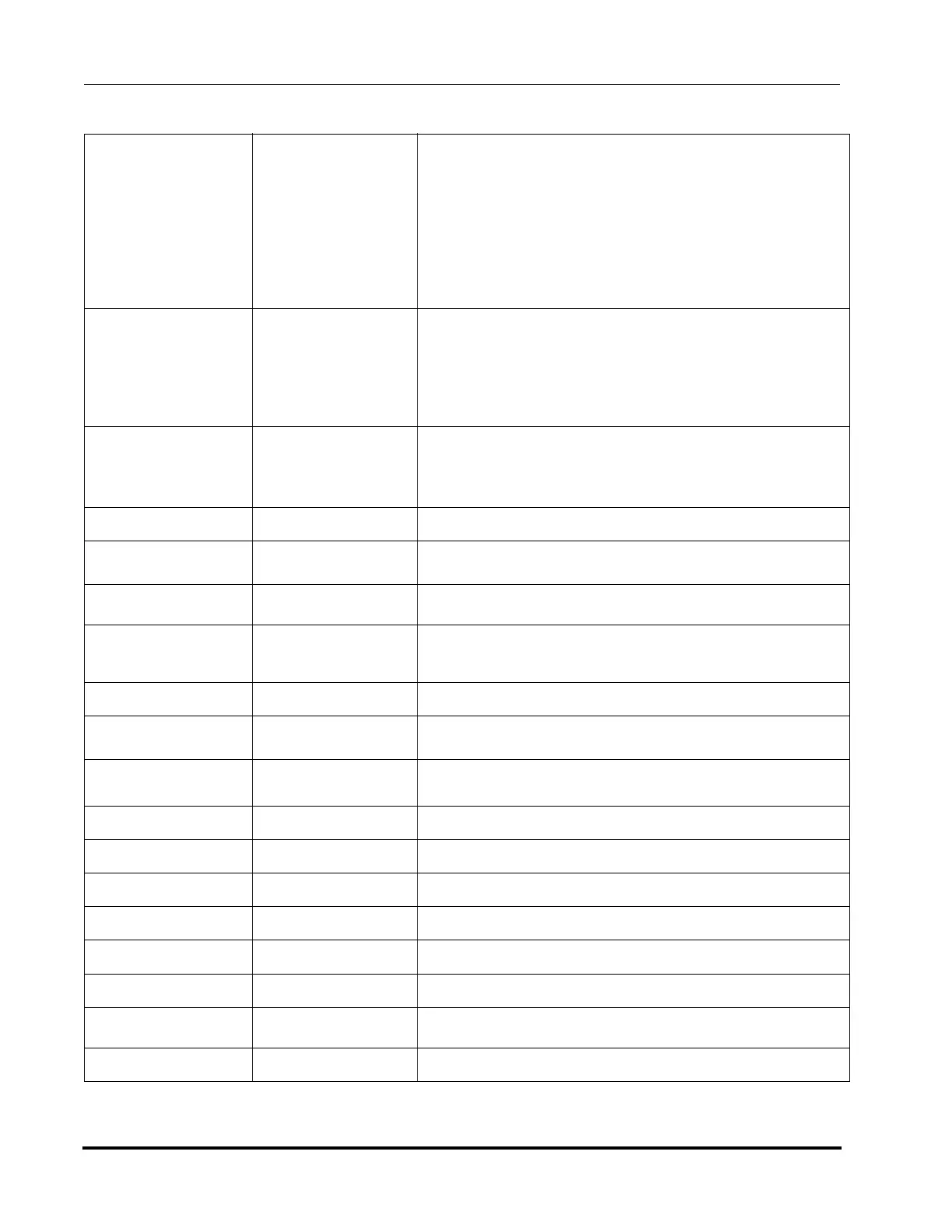

Total hardness

(°dH)

3.9 – 8.4 °dH

(70 - 150 ppm)

Maintain recommended levels to reduce scaling

Scaling affects heat transfer and can lead to crevice

corrosion.

Values below 100 ppm are strongly recommended as

there is a higher risk for scale above 5.6 °dH (100 ppm).

(Note: This assumes the majority of hardness is due to

calcium carbonate, CaCO

3

)

Alkalinity (HCO

3

)

70 - 250 ppm

Low levels cause copper corrosion, dissolution and

release into water.

High levels can cause increased chance of scaling.

Note: The alkalinity of interest is “methyl orange”

alkalinity or “m alkalinity”

Electrical

Conductivity

10 - 600 μS/cm

Conductivity above the recommended level indicates a

high concentration of ionic substances which results in

high dissolved solids and potential for particles and

scale.

Chlorides (Cl

-

)

< 100 ppm Higher levels can cause pitting corrosion.

Free Chlorine (Cl

2

)

< 0.5 ppm

Higher levels accelerates copper leaching by oxidation

and dissolution of the metal surface.

Sulphate (SO

4

2-

)

< 100 ppm

Levels higher than 100 ppm increase the risk of copper pitting

corrosion.

Electrical Resistivity 2,000 - 100,000 Ω-cm

Resistivity is the inverse of Conductivity.

Higher resistivity above 100,000 Ω-cm can result in copper

corrosion.

Hydrogen Sulfide (H

2

S)

< 0.05 ppm Higher levels can lead to corrosion, pitting, and copper fatigue.

Free (aggressive)

Carbon Dioxide (CO

2

)

< 5 ppm Higher levels can indicate oxidation of metals.

Nitrate (NO

3

-

)

< 100 ppm

Nitrate ions help to inhibit corrosion, similar to Sulphate (SO

4

2-

)

Higher levels increase the risk of copper pitting corrosion.

Iron (Fe) < 0.3 ppm Higher levels can increase the risk of galvanic corrosion.

Aluminum (Al) < 0.2 ppm Higher levels can increase the risk of galvanic corrosion.

Manganese < 0.5 ppm Higher levels can increase the risk of galvanic corrosion.

Silica < 50 ppm

Total Copper (Cu) < 0.3 ppm Higher levels can increase the risk of galvanic corrosion.

HCO

3

-

/ SO

4

2-

> 1 ppm Lower levels below 1 ppm add risk of copper pitting

Turbidity < 5 FTU

Higher turbidity levels are signs of high levels of microorganisms.

Clean water is less likely to form deposits.

Ammonium (NH

4

+

)

< 2 ppm Higher levels increase the risk of copper corrosion.

Table 3-7: Water Purity Properties

Loading...

Loading...