NO.

IN

CHAPTER

8

FLOWCHART

AND

ERROR

STATUS

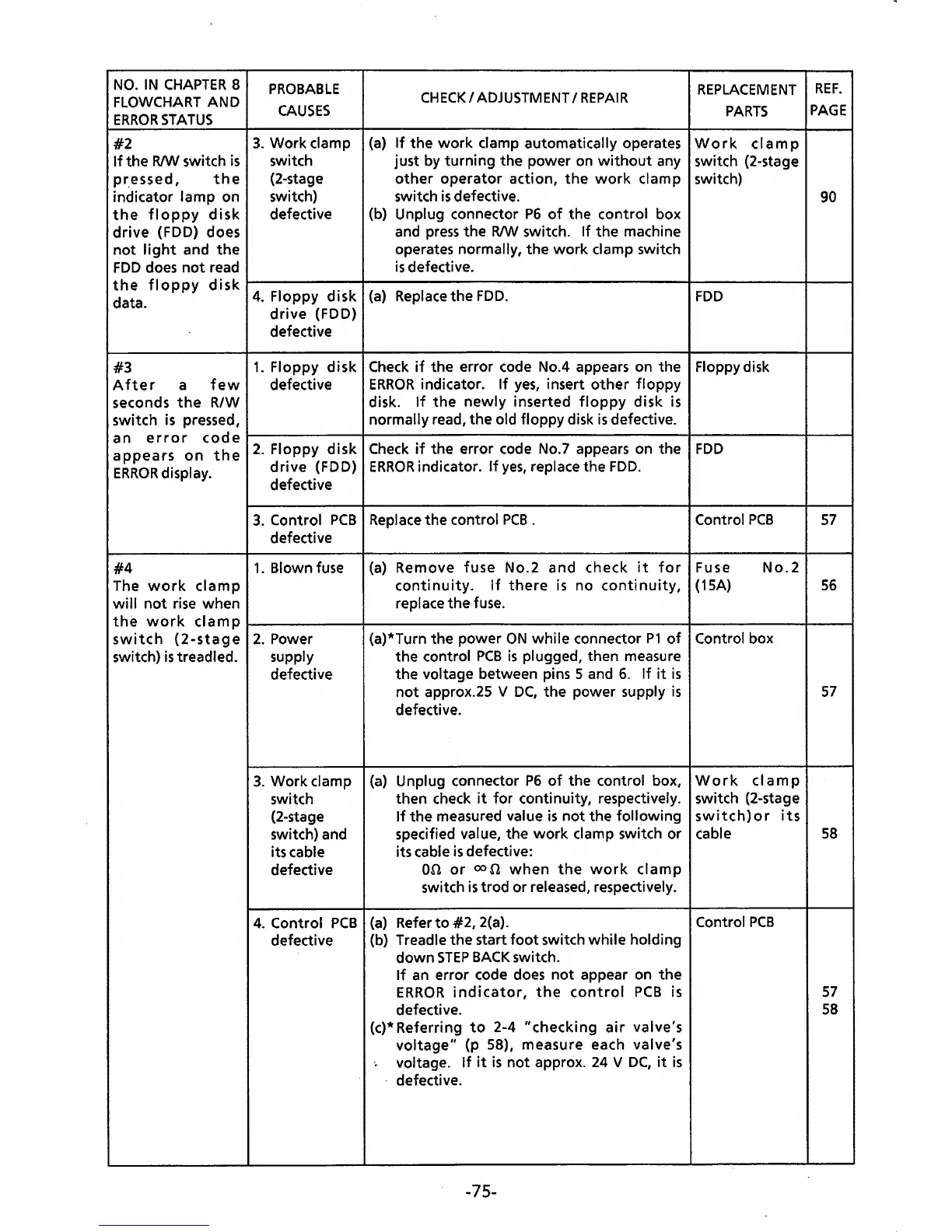

#2

If

the

R/W

switch

is

pr.essed,

the

indicator lamp on

the

floppy

disk

drive

(FDD) does

not

light

and

the

FDD

does

not

read

PROBABLE

CAUSES

3.

Work clamp

switch

(2-stage

switch)

defective

CHECK

I

ADJUSTMENT

I

REPAIR

(a)

If

the

work

clamp automatically operates

just by turning the power on

without

any

other

operator

action,

the

work

clamp

switch

is

defective.

(b) Unplug connector

P6

of

the control box

and

press

the R/W switch. If the machine

operates normally,

the

work

clamp switch

is

defective.

REPLACEMENT

PARTS

Work

clamp

switch (2-stage

switch)

REF.

PAGE

90

the

floppy

disk

t------+-----------------1---------1-~

data.

4.

Floppy

disk

(a)

Replace

the

FDD.

FDD

drive

(FDD)

defective

#3

1.

Floppy

disk

Check

if

the error code No.4 appears on the Floppydisk

After

a

few

defective

ERROR

indicator.

If

yes,

insert

other

floppy

seconds

the

RIW disk.

If

the

newly

inserted

floppy

disk

is

switch

is

pressed, normally read, the old floppy disk

is

defective.

an

error

code~----------+---------------------------------4-----------~--~

appears

on

the

2.

Floppy

disk

Check

if

the error code No.7 appears on the

FDD

ERROR

display.

drive

(FDD)

ERROR

indicator.

If

yes,

replace the

FDD.

defective

#4

The

work

clamp

will

not

rise

when

3.

Control

PCB

Replace

the control

PCB

.

defective

Control

PCB

1.

Blown fuse

(a)

Remove

fuse

No.2 and check

it

for

Fuse

No.2

continuity.

If

there

is

no

continuity,

(15A)

replace

the

fuse.

57

56

the

work

clamp

l------------+---------------------------l----------+-----1

switch

(2-stage

switch)

is

treadled.

2.

Power

supply

defective

3. Work clamp

switch

(2-stage

switch) and

its cable

defective

4.

Control

PCB

defective

(a)*Turn the power

ON

while

connector

P1

of

Control box

the control

PCB

is

plugged, then measure

the voltage between pins 5 and

6.

If

it

is

not

approx.25 V

DC,

the

power supply

is

defective.

(a)

Unplug connector

P6

of

the control box,

then check

it

for

continuity, respectively.

If

the measured value

is

not

the following

specified value, the

work

clamp switch or

its cable

is

defective:

on

or

00

n

when

the

work

clamp

switch

is

trod

or released, respectively.

(a)

Refer

to

#2, 2(a).

(b) Treadle the start

foot

switch while holding

down

STEP

BACK

switch.

If

an

error code does

not

appear on

the

ERROR

indicator,

the

control

PCB

is

defective.

(c)* Referring

to

2-4

"checking

air

valve's

voltage"

(p 58), measure each valve's

·.

voltage.

If

it

is

not

approx.

24

V

DC,

it

is

· defective.

-75-

Work

clamp

switch (2-stage

switch)or

its

cable

Control

PCB

57

58

57

58

Loading...

Loading...