NO.

IN

CHAPTER.

8

FLOWCHART

AND

ERROR

STATUS.

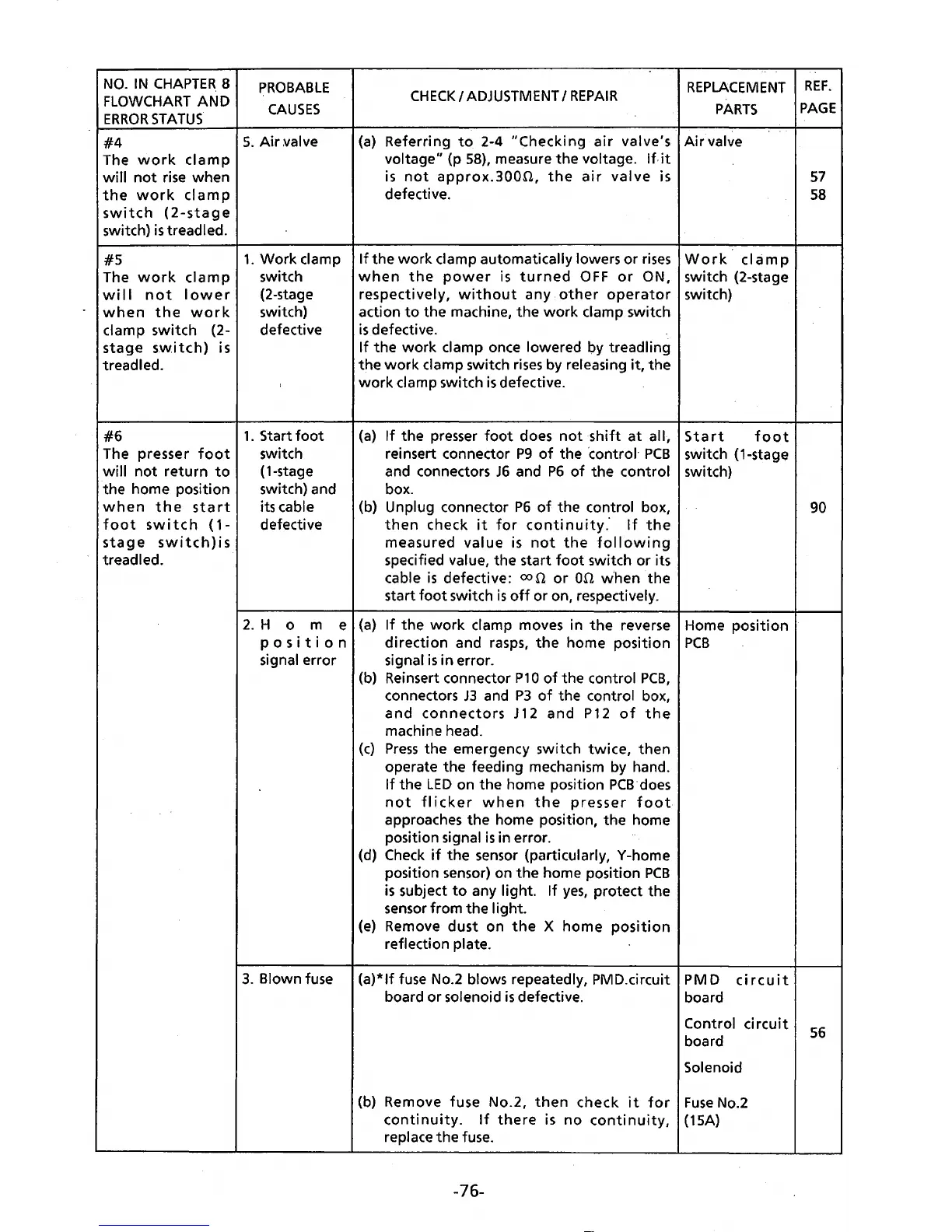

#4

The

work

clamp

will

not

rise when

the

work

clamp

switch

(2-stage

switch)

is

treadled.

#5

The

work

clamp

will

not

lower

when

the

work

clamp switch (2-

stage

sw.i

tch)

is

treadled.

#6

The presser

foot

will

not

return

to

the home position

when

the

start

foot

switch

(1-

stage

switch)is

treadled.

PROBABLE

CAUSES

5.

Air

~alve

1.

Work

clamp

switch

(2-stage

switch)

defective

1.

Start

foot

switch

(1-stage

switch) and

its cable

defective

CHECK

I

ADJUSTMENT

I

REPAIR

REPLACEMENT

PARTS

(a)

Referring

to

2-4

"Checking

air

valve's

Air

valve

voltage" (p

58),

measure

the

voltage. If.

it

is

not

approx.300n,

the

air

valve

is

defective.

If

the

work

clamp automatically lowers

or

rises

Work

cIa

m p

when

the

power

is

turned

OFF

or

ON, switch (2-stage

respectively,

without

any

other

operator

switch)

action

to

the machine,

the

work

clamp switch

is

defective.

If

the

work

clamp once lowered by treadling

the

work

clamp switch

rises

by releasing

it,

the

work

clamp switch

is

defective.

(a)

If

the

presser

foot

does

not

shift

at

all,

reinsert connector

P9

of

the ·control·

PCB

and connectors

JG

and

P6

of

the

control

box.

(b) Unplug connector

P6

of

the control box,

then

check

it

for

continuity.

If

the

measured

value

is

not

the

following

specified value, the start

foot

switch

or

its

cable

is

defective:

con

or

on

when

the

start

foot

switch

is

off

or

on, respectively.

Start

foot

switch

(1-stag~

switch)

2.

H o m e

(a}

If

the

work

clamp moves in

the

reverse Home position

posit

i o n

direction

and rasps,

the

home position

PCB

signal error signal

is

in error.

(b) Reinsert connector

P1

0

of

the control

PCB,

connectors

J3

and

P3

of

the control box,

and

connectors

J

12

and

P12

of

the

machine head.

(c)

Press

the emergency switch

twice,

then

operate

the

feeding mechanism by hand.

If

the

LED

on

the

home position

PCB·does

not

flicker

when

the

presser

foot

approaches

the

home position,

the

home

position signal

is

in error.

(d)

Check

if

the

sensor (particularly, Y-home

position sensor) on

the

home position

PCB

is

subject

to

any light.

If

yes,

protect the

sensor from

the

light.

(e)

Remove

dust

on

the

X

home

position

reflection plate.

3.

Blown fuse

(a)*lf

fuse No.2 blows repeatedly, PMD.circuit PM D

circuit

board

or

solenoid

is

defective. board

Control

circuit

board

Solenoid

(b) Remove fuse No.2,

then

check

it

for

Fuse

No.2

continuity.

If

there

is

no

continuity,

(15A)

replace

the

fuse.

-76-

REF.

PAGE

57

58

90

56

Loading...

Loading...