130

SYSTEM ANALYSIS

IGNITION OUTPUT

Ignition Primary Circuit

Resistance Test

Disconnect the battery cables at the battery.

Calibrate ohmmeter to low ohms scale.

With key switch OFF, remove the EMM J1-B con-

nector and measure resistance of each primary

circuit. Note resistance reading between each pri-

mary wire and ground. Refer to engine wiring dia-

gram.

IMPORTANT: A reading of less than 2 ohms is

acceptable. Make sure meter is calibrated to read

1 ohm or less.

Results:

Primary circuit (complete circuit) resistance read-

ing is higher than 2 Ω:

• Repair primary circuit wiring or coil grounds as

needed and retest.

• Replace faulty coils or wiring.

Primary circuit resistance reading less than 2 Ω or

within specification and EMM ignition output volt-

age is 130 V or higher:

• Refer to Secondary Winding Resistance Test

on p. 141. Repair high tension spark plug lead

or replace ignition coil and/or high tension spark

plug lead assembly.

Crankshaft Position Sensor (CPS)

Test

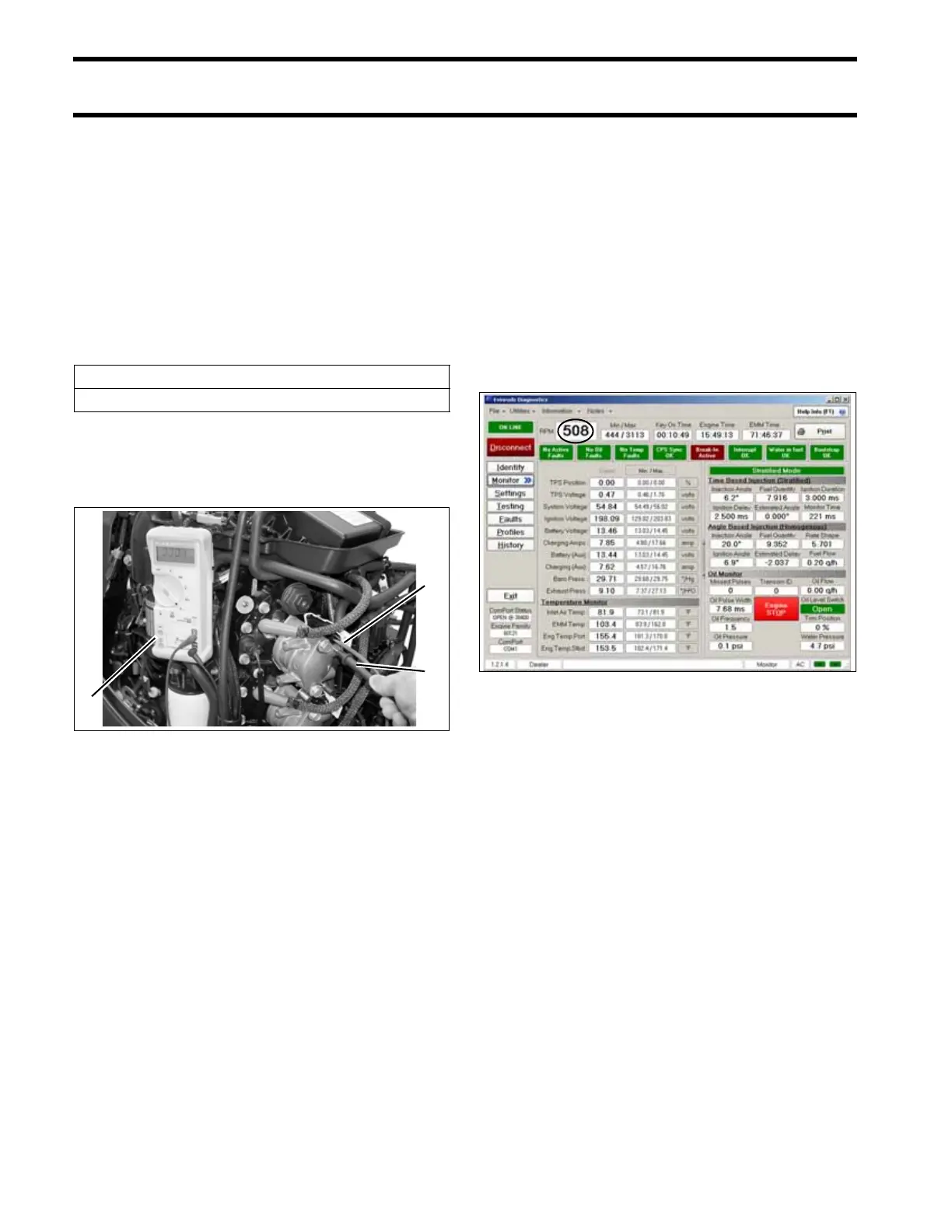

Use the Evinrude Diagnostics Software program

to check RPM reading. An RPM display higher

than zero indicates a CPS signal to the EMM.

Cranking RPM is typically 175 RPM.

Observe Engine RPM and Power ON Time dis-

play fields of the engine Monitor screen. “ON

Time” should be continuous and should not reset

unless the key switch is turned OFF or power to

the EMM is interrupted.

Check CPS resistance (560 Ω ± 10%). Make cer-

tain ohmmeter is calibrated properly. Refer to

Crankshaft Position Sensor (CPS) Test on

p. 139.

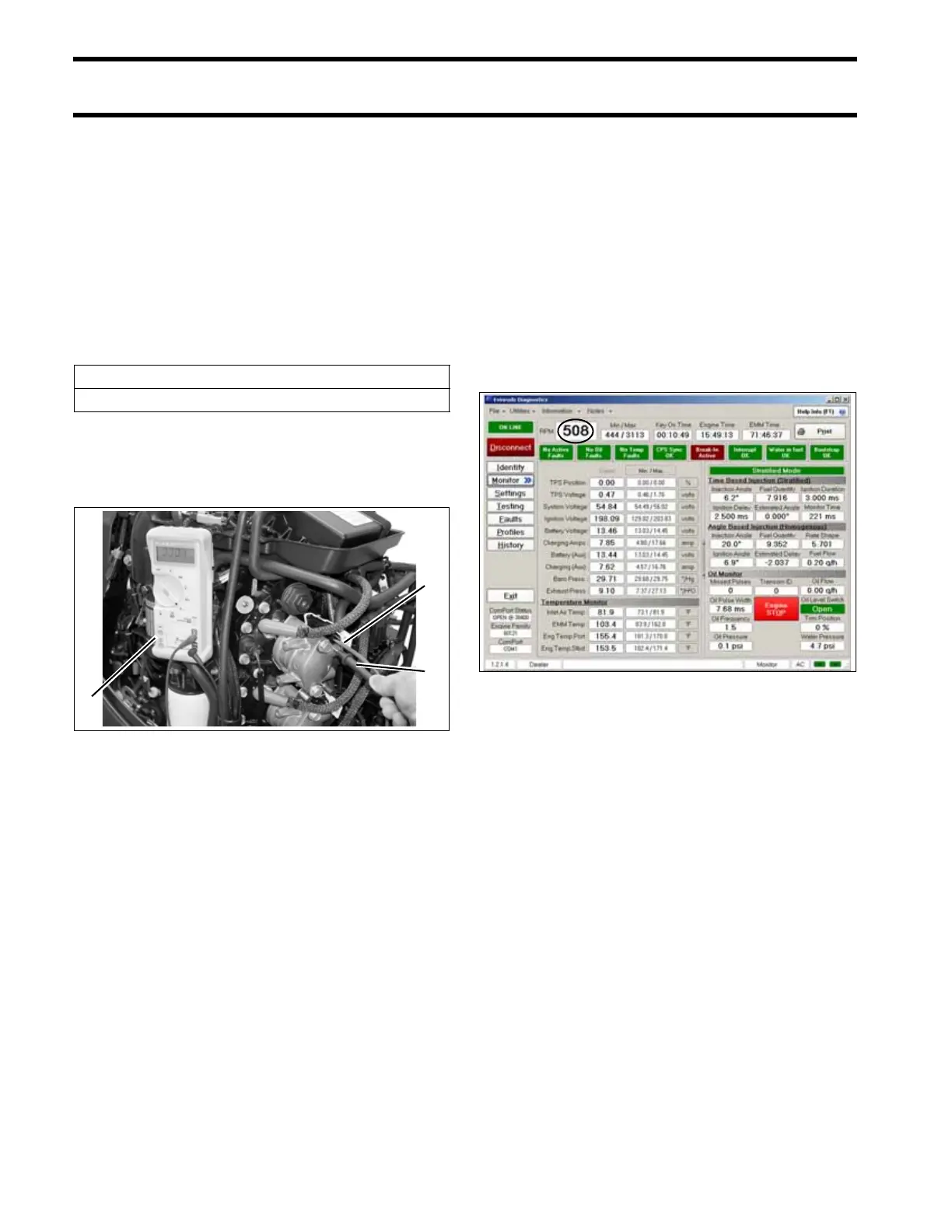

Ignition Coil Primary Circuit Resistance

0.090 ± 0.005 Ω.

1. Ohmmeter, low ohms scale

2. Red meter lead, with pin adapter

3. Black meter lead to ground

005440

2

3

1

Engine Monitor Screen, Engine RPM display 005141

Loading...

Loading...