250

POWERHEAD

ASSEMBLY

or just below the surface of piston. Rings must

move freely in piston ring groove.

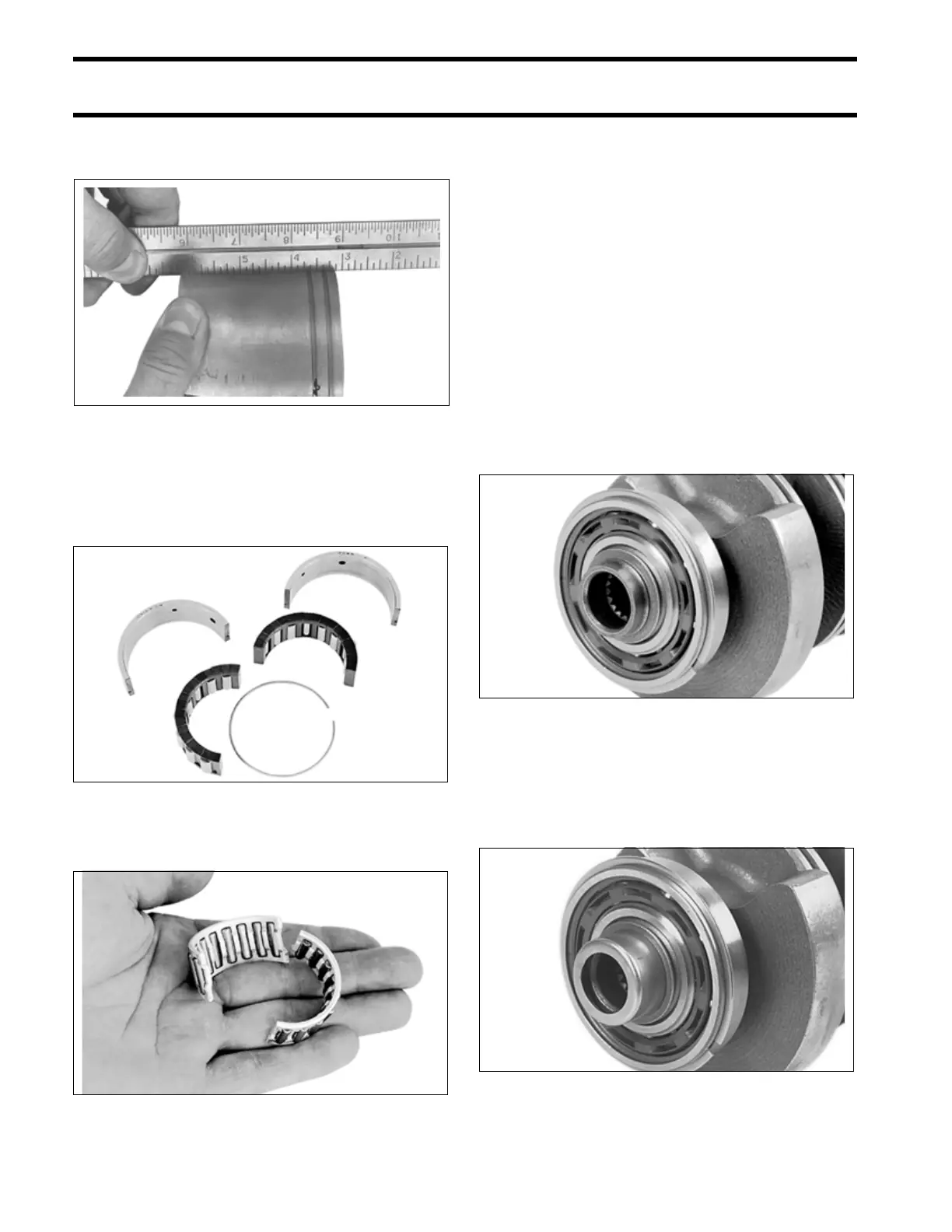

Bearings

Inspect center main bearing and split sleeves for

excess wear, nicks, or scratches. Replace, if nec-

essary.

Inspect crankshaft rod bearings for excess wear,

nicks, or scratches. Replace, if necessary.

ASSEMBLY

IMPORTANT: Proceed slowly. Make no forced

assemblies unless a pressing operation is called

for. All internal components must be perfectly

clean and lightly coated with outboard lubricant.

IMPORTANT: Use new wrist pin retaining rings,

gaskets, seals, and O-rings during assembly.

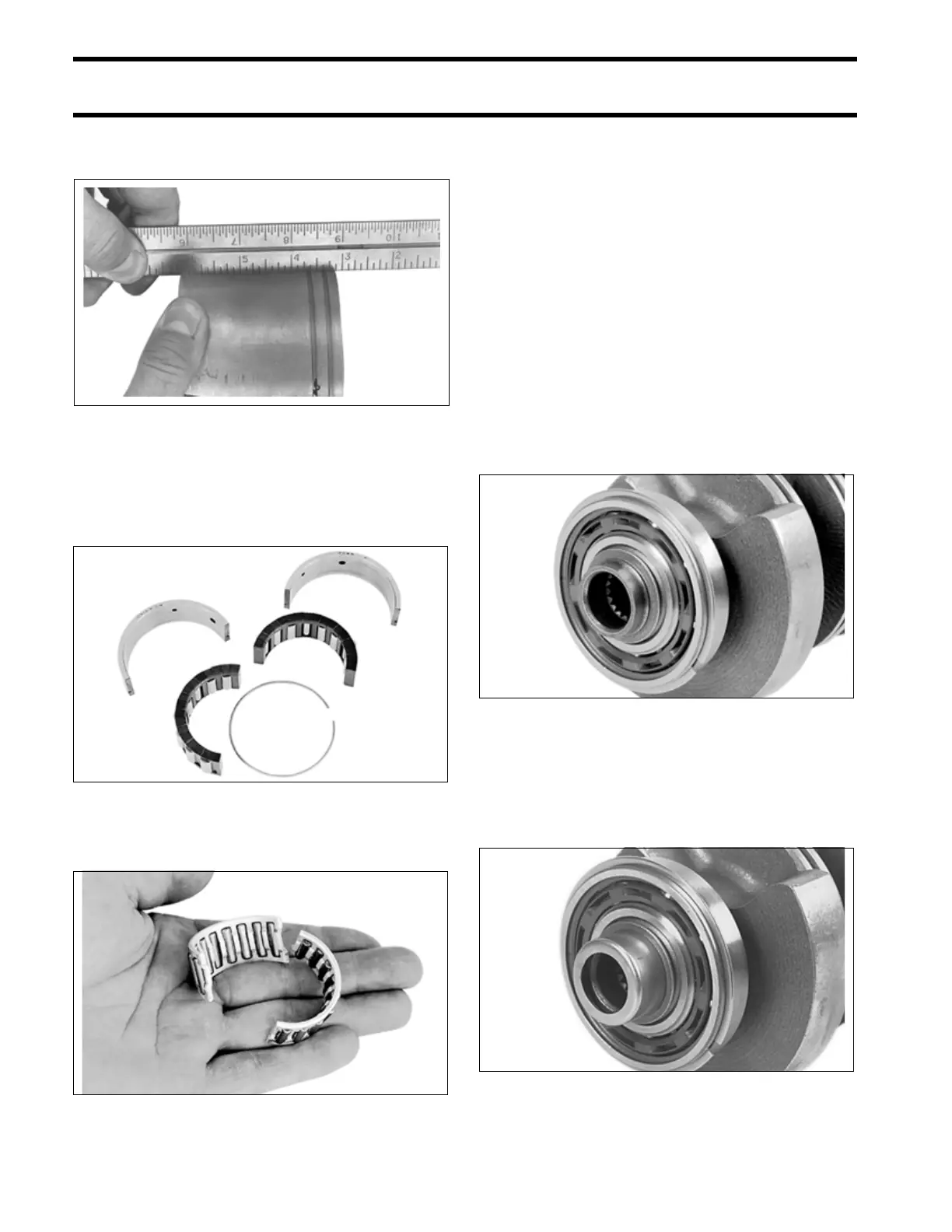

Crankshaft

Oil the end of the crankshaft. Use Crankshaft

Bearing/Sleeve Installer, P/N 338647, and place a

new lower main bearing onto crankshaft with let-

tered side facing the tool. Install bearing until it

seats on the crankshaft.

Oil the end of the crankshaft. Place a new sleeve

in the Crankshaft Bearing/Sleeve Installer,

P/N 338647, and drive the sleeve onto the crank-

shaft until the installer contacts the lower main

bearing.

31796

24381

24377

29020

29021

Loading...

Loading...