379

TRIM AND TILT

SERVICING – THREE PISTON SYSTEM

13

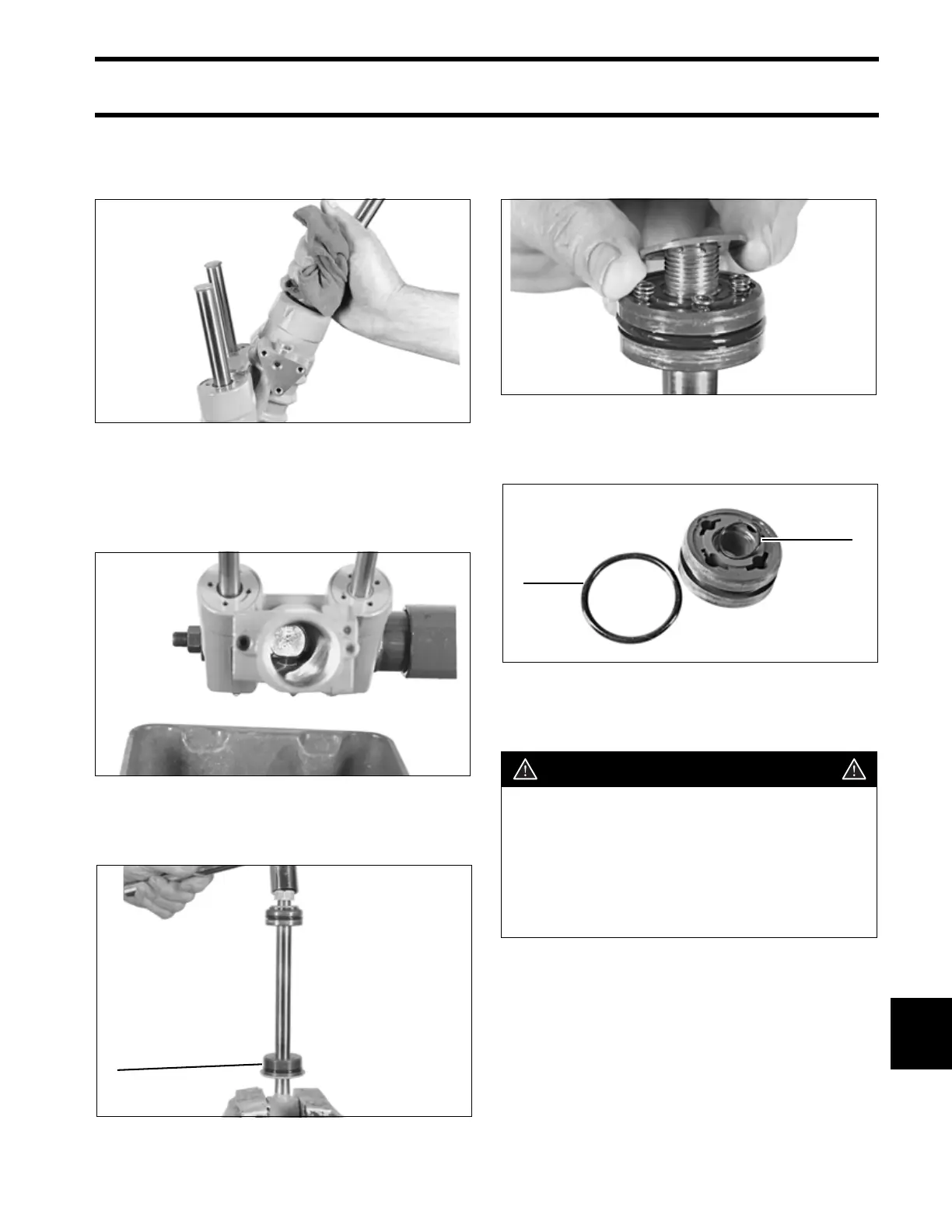

Slowly pull the piston out with a rag wrapped

around the rod and the top of the cylinder. Drain

the remaining fluid from the cylinder.

Inspect the bore of the tilt cylinder for excessive

scoring. If the bore of the tilt cylinder is scored or

damaged, the hydraulic assembly must be

replaced.

Clamp the rod eye tightly in a soft jaw vise.

Remove the nut from the piston end of the rod.

Remove the washer. Slide the tilt piston off the

rod. Be careful not to lose the springs, plungers,

or small check valves in the piston assembly.

Remove and discard the small inner O-ring and

large outer O-ring.

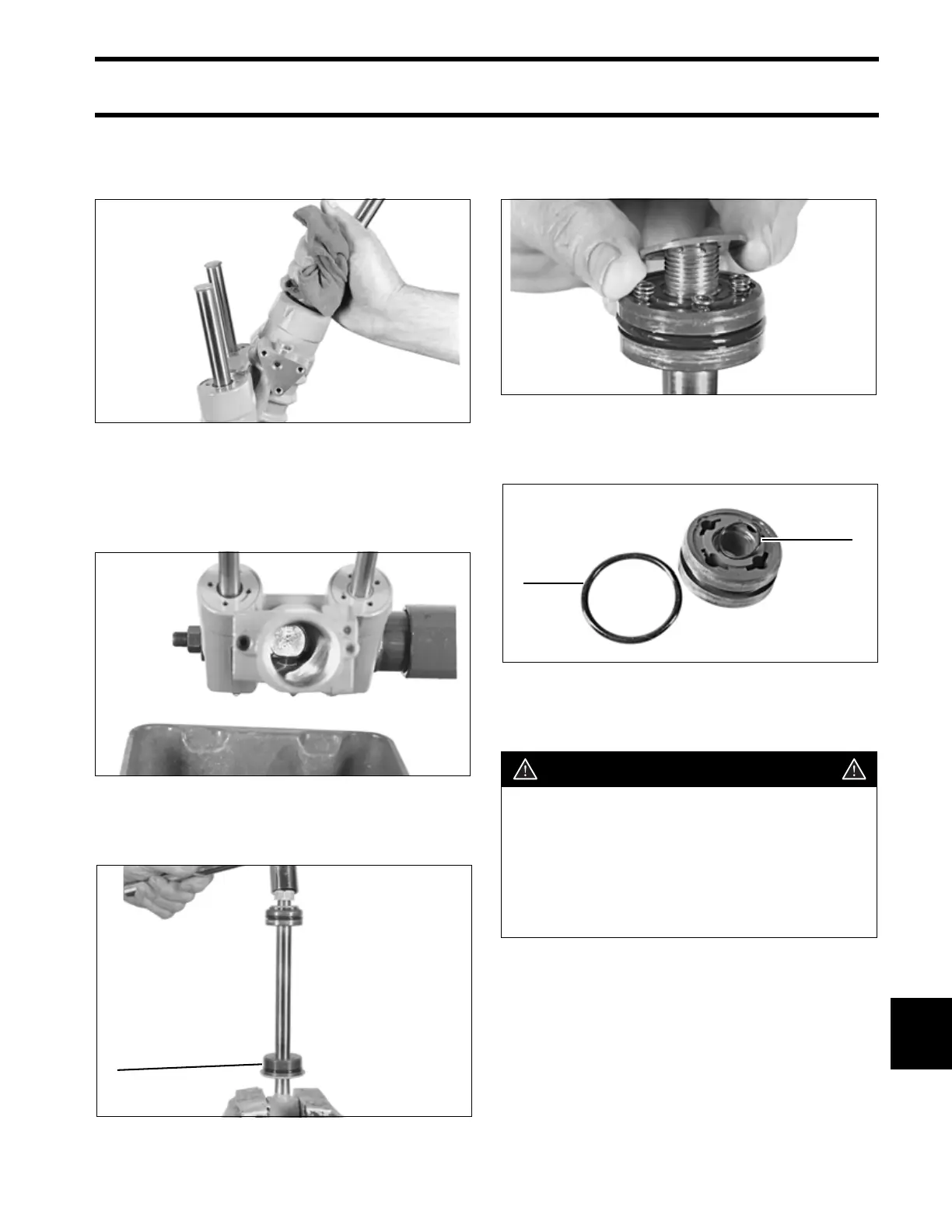

Tilt Piston Identification

41765

41767

1. End cap 41781

1

41784

1. Small inner O-ring

2. Large outer O-ring

41819

WARNING

Different tilt pistons are used on hydraulic

units for various outboard models. All

plungers and check balls are identical.

The tilt piston assemblies contain valving

specific to certain models. To provide

impact protection, it is important the cor-

rect piston assembly be installed.

1

2

Loading...

Loading...