259

POWERHEAD

ASSEMBLY

10

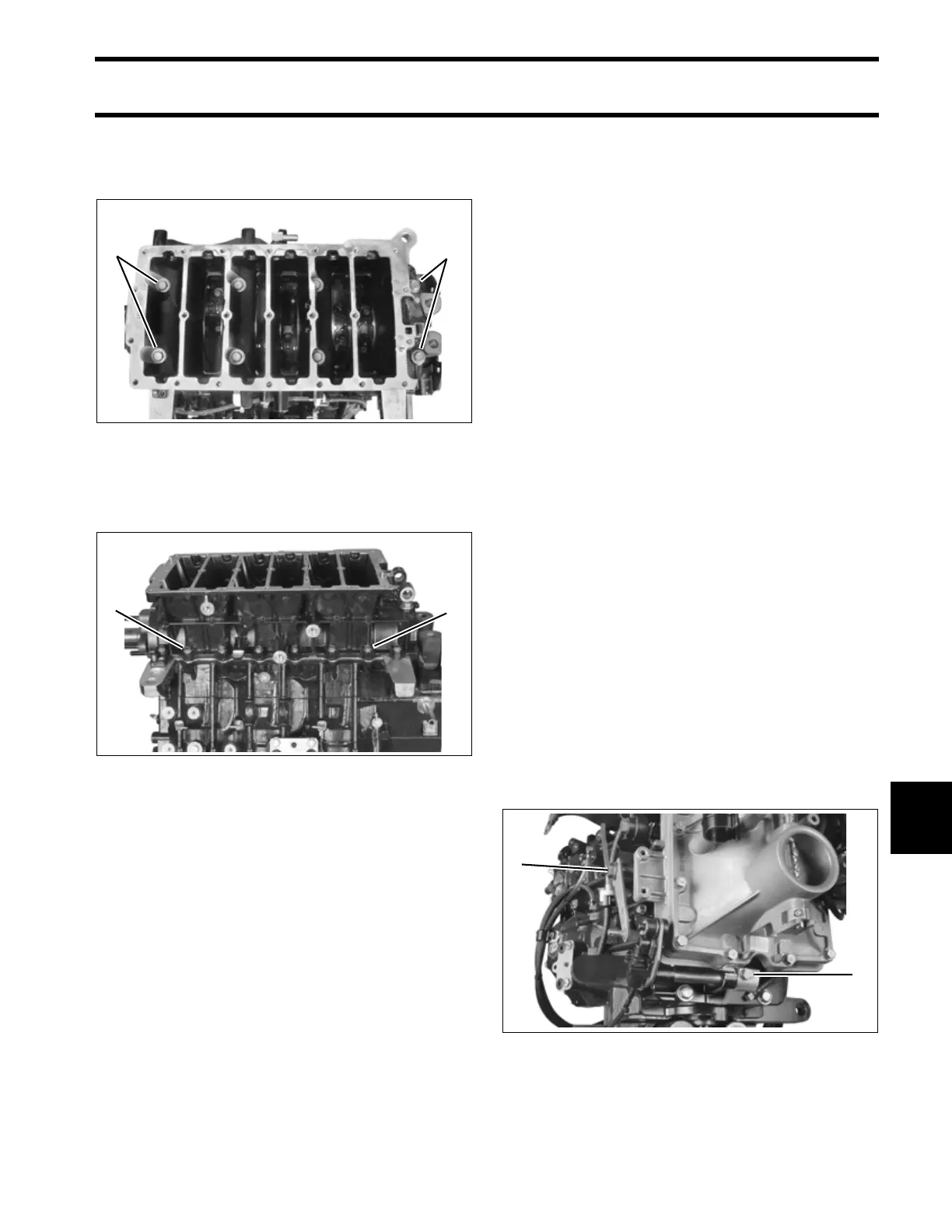

Torque main bearing screws in stages to 31 to 35

ft. lbs. (42 to 47.5 N·m). Begin with the center

screws and work outward in a spiral pattern.

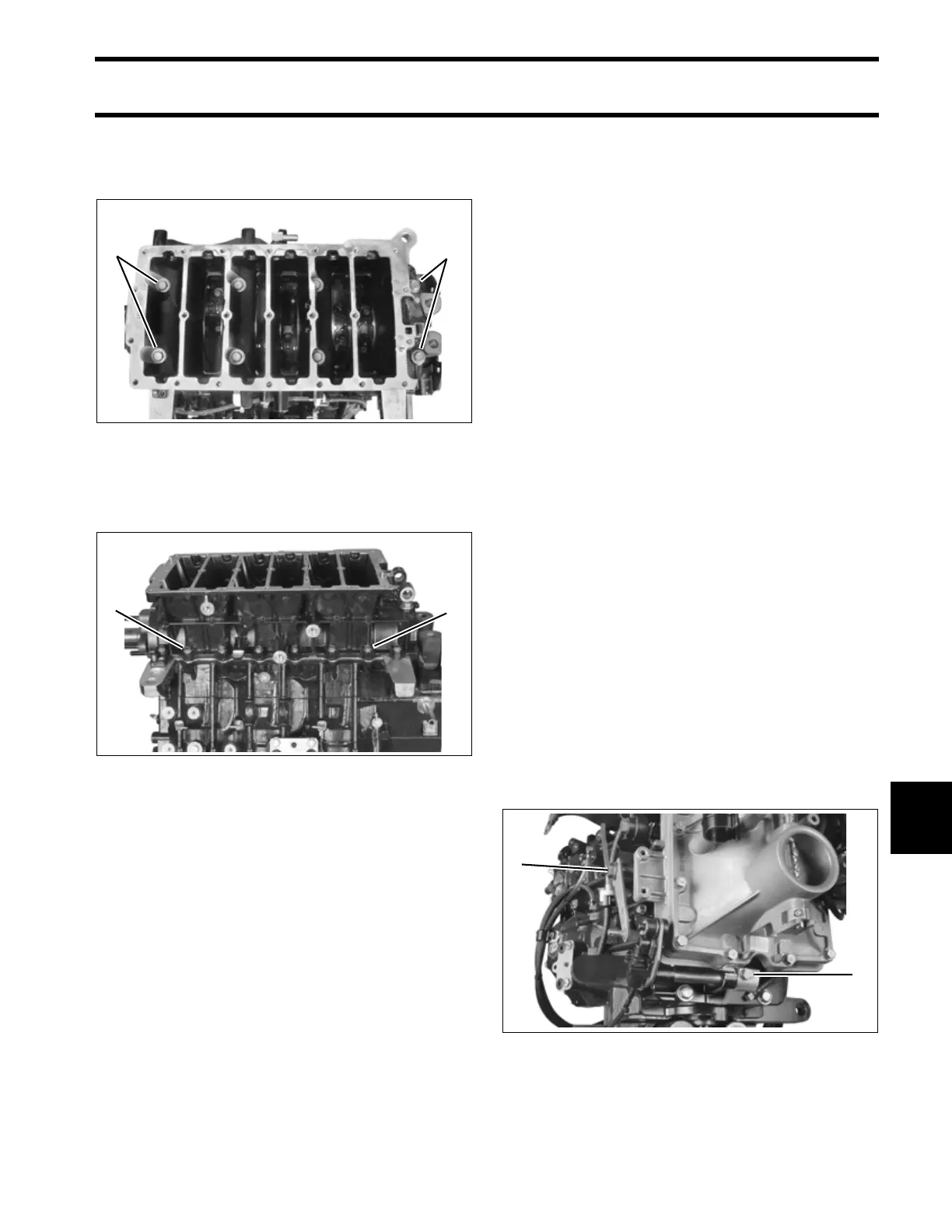

Apply Triple-Guard grease to crankcase flange

screws. Install screws and torque to 60 to 84 in.

lbs. (7 to 9.5 N·m).

Test that the crankshaft spins freely without bind-

ing.

IMPORTANT: After powerhead has been

assembled, allow at least two hours for Gel-Seal II

to cure before running outboard.

General

Connect all crankcase recirculating hoses. Refer

to Recirculation Hose Routings and Check

Valve Diagrams – V4 on p. 213, Recirculation

Hose Routings and Check Valve Diagrams –

V6 on p. 211, or POWERHEAD VIEWS on p. 266.

Install pressure valve assembly. Refer to PRES-

SURE RELIEF VALVE SERVICING on p. 233.

Install the throttle body and reed plate assemblies.

Refer to INTAKE MANIFOLD on p. 196.

Lubricate shift linkage bosses at the base of the

crankcase with Triple-Guard grease. Insert bush-

ings into bosses.

Apply Triple-Guard grease to the shaft of the shift

lever assembly. Guide shaft through bushings in

crankcase.

Install shift rod lever and tighten retaining screw

60 to 84 in. lbs. (7 to 9.5 N·m).

Apply Triple-Guard grease to shoulder of shift arm

screw and Nut Lock to threads. Install arm, screw,

and washer and torque screw to 120 to 144 in.

lbs. (14 to 16 N·m).

1. Main bearing screws (6 on V4; 8 on V6) 005313

1. Flange screws (12 on V4; 16 on V6) 005306

11

11

1. Shift arm screw

2. Shift lever screw

005294

2

1

Loading...

Loading...