215

OILING SYSTEM

PRIMING

8

PRIMING

The oiling system of the outboard must be primed:

• After the initial installation of the outboard (pre-

delivery);

• Whenever the oil supply to the oil lift pump is

disconnected or disrupted; and

• Whenever an oiling system component is

removed or replaced.

Oil Hose Connections

Insert the end of the oil supply hose (from the oil

tank) into a suitable container.

Squeeze the oil primer bulb to flow oil from the oil

tank.

Once oil flow is observed, connect the oil tank

hose to the outboard’s oil supply hose and secure

with 14.5 mm Oetiker clamp.

Oil Distribution Manifold Priming

Follow these steps for initial outboard set-up:

• Position outboard in lowest trim/tilt position.

• Squeeze the oil primer bulb to flow oil from the

hose connection, through the filter, to the oil

pump.

• Visually inspect filter to ensure that all air has

been purged.

• Continue squeezing the primer until oil flows

through the distribution manifold into the oil dis-

tribution hoses and to the crankcase fittings. All

air must be eliminated from oil lines.

• Use the Evinrude Diagnostics Software pro-

gram to confirm that the EMM is programmed

for the type of oil being used.

• Start the outboard and use the oil priming func-

tion in the software for a minimum of 90 sec-

onds to make sure the system is completely

primed.

WARNING

To prevent injury from contact with rotat-

ing propeller, always remove the propeller

before running on a flushing device.

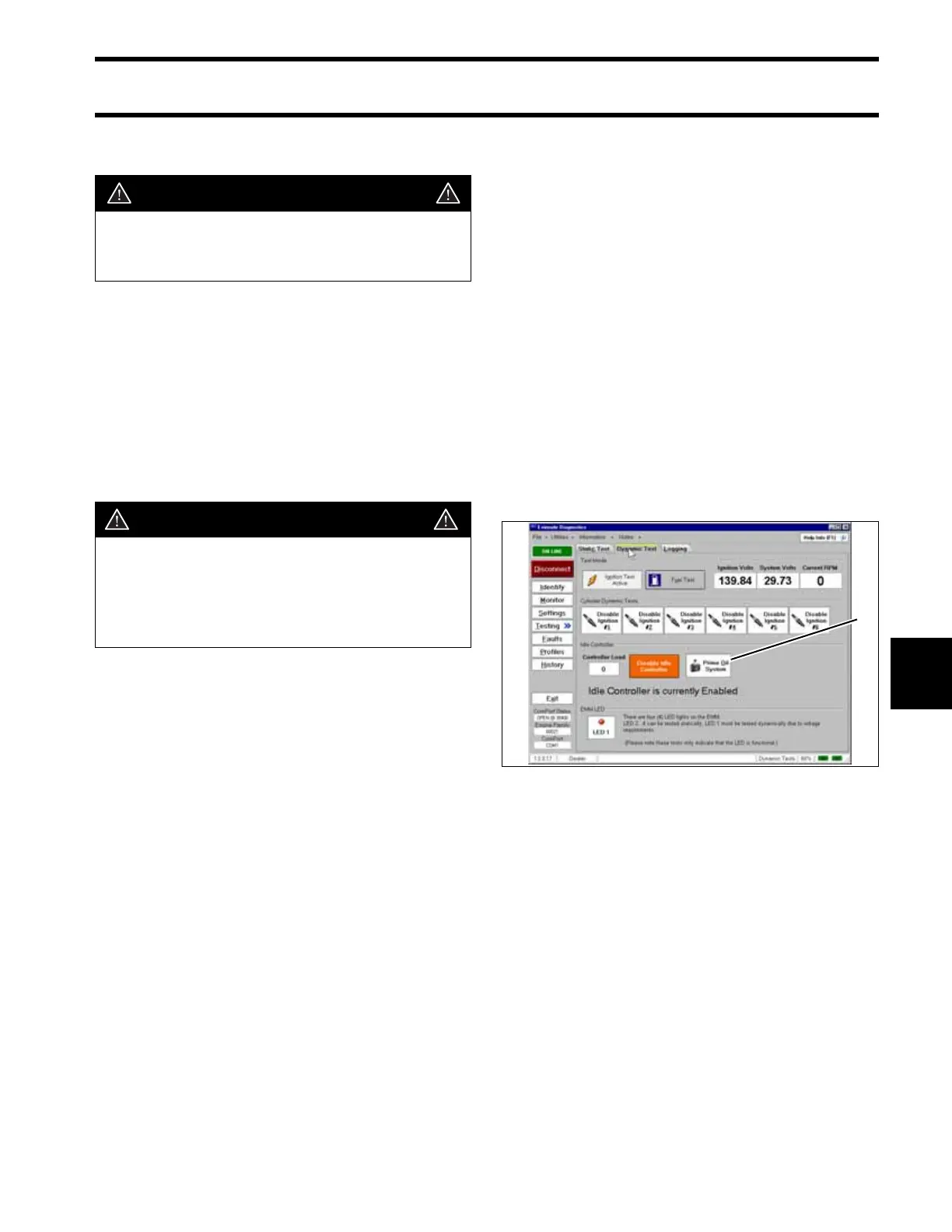

WARNING

Always use caution while working around

machinery with moving parts. The follow-

ing set-up procedures require running

tests that are performed with the out-

board’s motor cover removed.

Dynamic Tests Screen

1. Prime Oil button

005137

1

Loading...

Loading...