221

OILING SYSTEM

OILING SYSTEM TESTS

8

Static Test

Remove oil distribution hose from fitting at crank-

case. Squeeze oil supply primer bulb to provide oil

to injection pump.

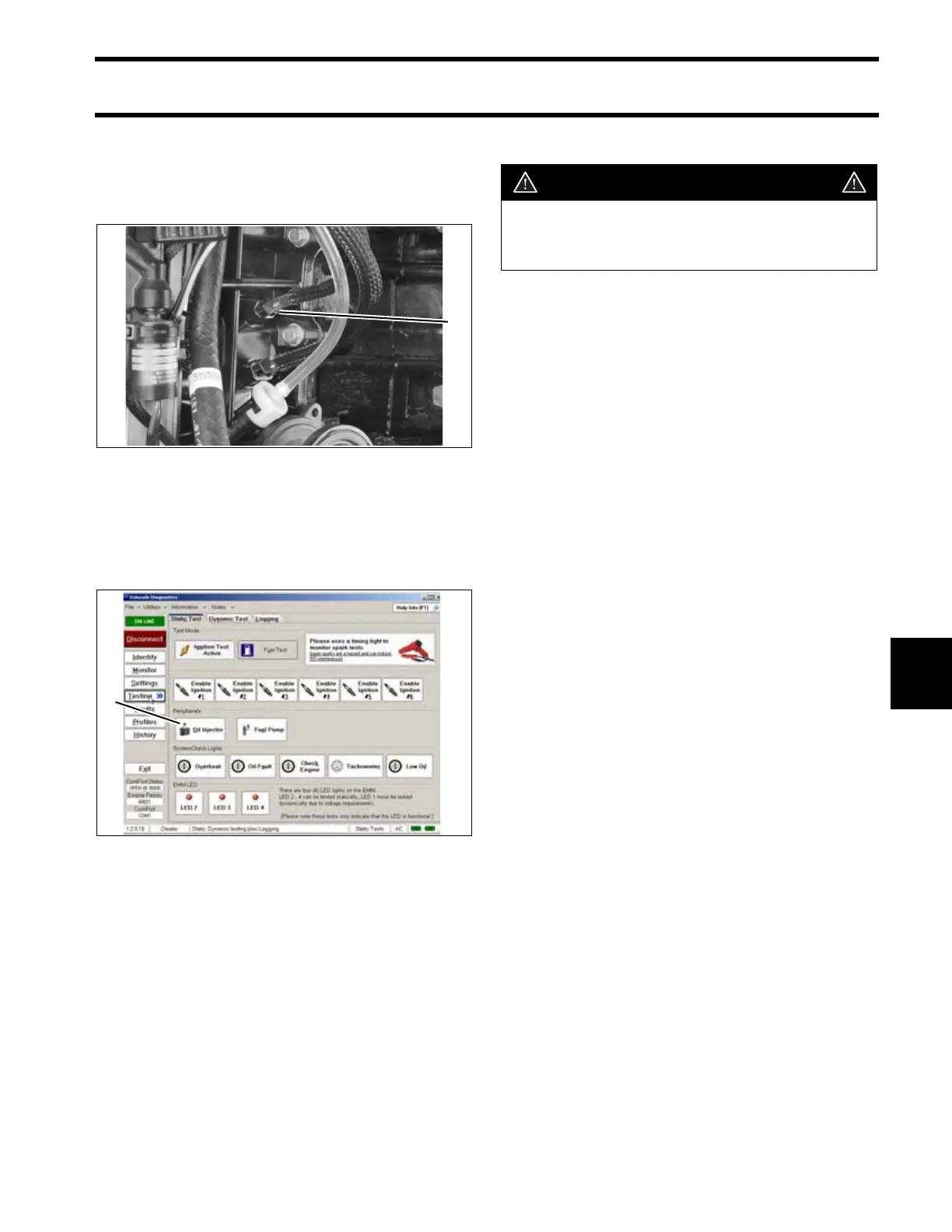

Use the oil injector test of the Evinrude Diagnos-

tics Software program to activate injector. Confirm

that a small amount of oil is discharged while

injection pump is activated.

Results:

• Oil flows from distribution hose, compare to oil

flow at other distribution hoses.

• No oil discharge, compare to oil flow at other

distribution hoses. If one or more hoses fail to

discharge oil, check for a kinked or restricted

hose before replacing the oil injection pump

assembly.

Oil Injection Fittings Flow Test

Confirm that the oil injection fittings of the cylinder

and crankcase assembly allow fluid to move.

Remove oil distribution hose from fitting. Connect

1/8 in. I.D. (3 mm) clear vinyl tubing to the fitting.

Use a syringe filled with isopropyl alcohol to force

fluid through the fitting.

LOW OIL Sending Unit Test

Remove the oil from the oil tank, and turn the key

switch ON. The LOW OIL light/warning of the Sys-

temCheck gauge should activate. Once the warn-

ing has been verified, turn the key switch ON and

refill the oil tank. Confirm that the LOW OIL warn-

ing stops as the oil level exceeds one-quarter of

oil tank’s capacity.

TYPICAL

1. Fitting at crankcase

005348

Static Tests Screen

1. Oil injector test button

005146

1

1

WARNING

To prevent accidental starting while ser-

vicing, disconnect battery cables at the

battery.

Loading...

Loading...