314

GEARCASE

SHIFT ROD ADJUSTMENT

SHIFT ROD

ADJUSTMENT

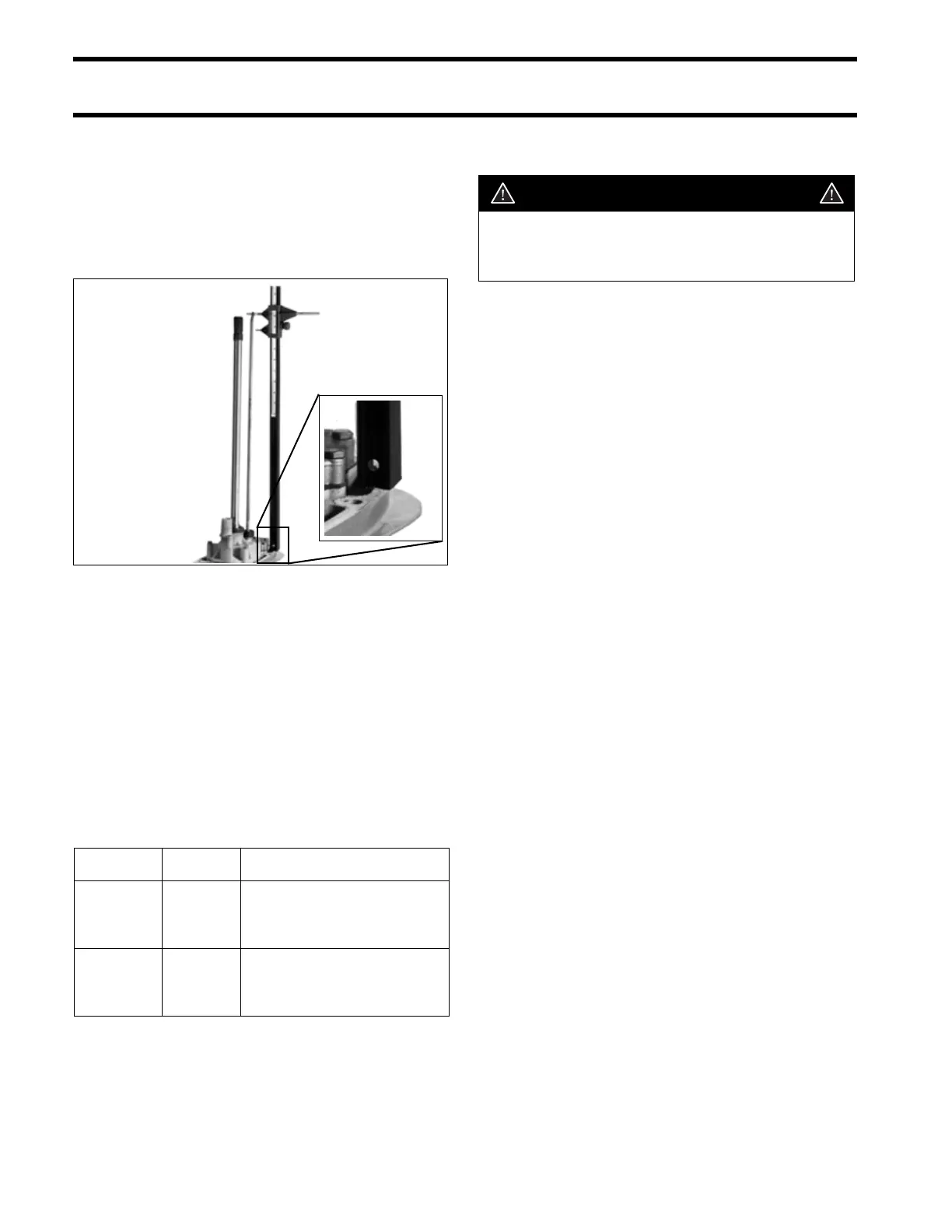

Check the shift rod height from the shift rod hole to

the surface of the gearcase using Universal Shift

Rod Height Gauge, P/N 389997.

With the shift rod and detent lever in NEUTRAL,

rotate the shift rod up or down as necessary for

correct adjustment. Once correct height is

achieved, rotate rod one half turn or less to face

offset forward.

IMPORTANT: The NEUTRAL detent is a two-

step design. Make sure the NEUTRAL detent ball

is in the center step before checking shift rod

height.

Shift Rod Heights

DISASSEMBLY

IMPORTANT: Clean and inspect all components

during disassembly. Replace any damaged com-

ponents, seals, O-rings, and gaskets upon assem-

bly.

Remove the propeller and mounting hardware.

Drain and inspect oil as described in LUBRICANT

on p. 307.

Remove gearcase as described in REMOVAL

AND INSTALLATION on p. 308.

Remove water pump as described in WATER

PUMP on p. 311.

Pre-Disassembly Inspection

Before disassembling the gearcase, examine the

following:

• Gearcase Housing — Check for visible dam-

age to skeg, strut, anti-ventilation plate, bullet,

and mating surface. Check seal areas for visible

signs of lubricant leakage.

• Propeller Shaft — Check for bent or damaged

shaft. Check for twisted splines and damaged

threads.

• Shift Rod — Check for misadjusted, bent, or

binding rod. A misadjusted shift rod height can

cause shift difficulty, loss of boat and outboard

control, and gearcase damage.

COA6166

Model Type Height

20 in. (L)

“S2” (V4)

“O” (V6)

“L” (V6)

20 15/16 in.

(20.945 in./ 532 mm)

± 1/2 Half Turn

25 in. (X)

“O” (V4)

“M” (V6)

25 15/16 in.

(25.945 in./659 mm)

± 1/2 Turn

WARNING

Wear safety glasses to avoid personal

injury, and set compressed air pressure to

less than 25 psi (172 kPa).

Loading...

Loading...