27

ENG

“Ultrasound for fancoil” +0300059IE - rel. 1.7 - 24.10.2022

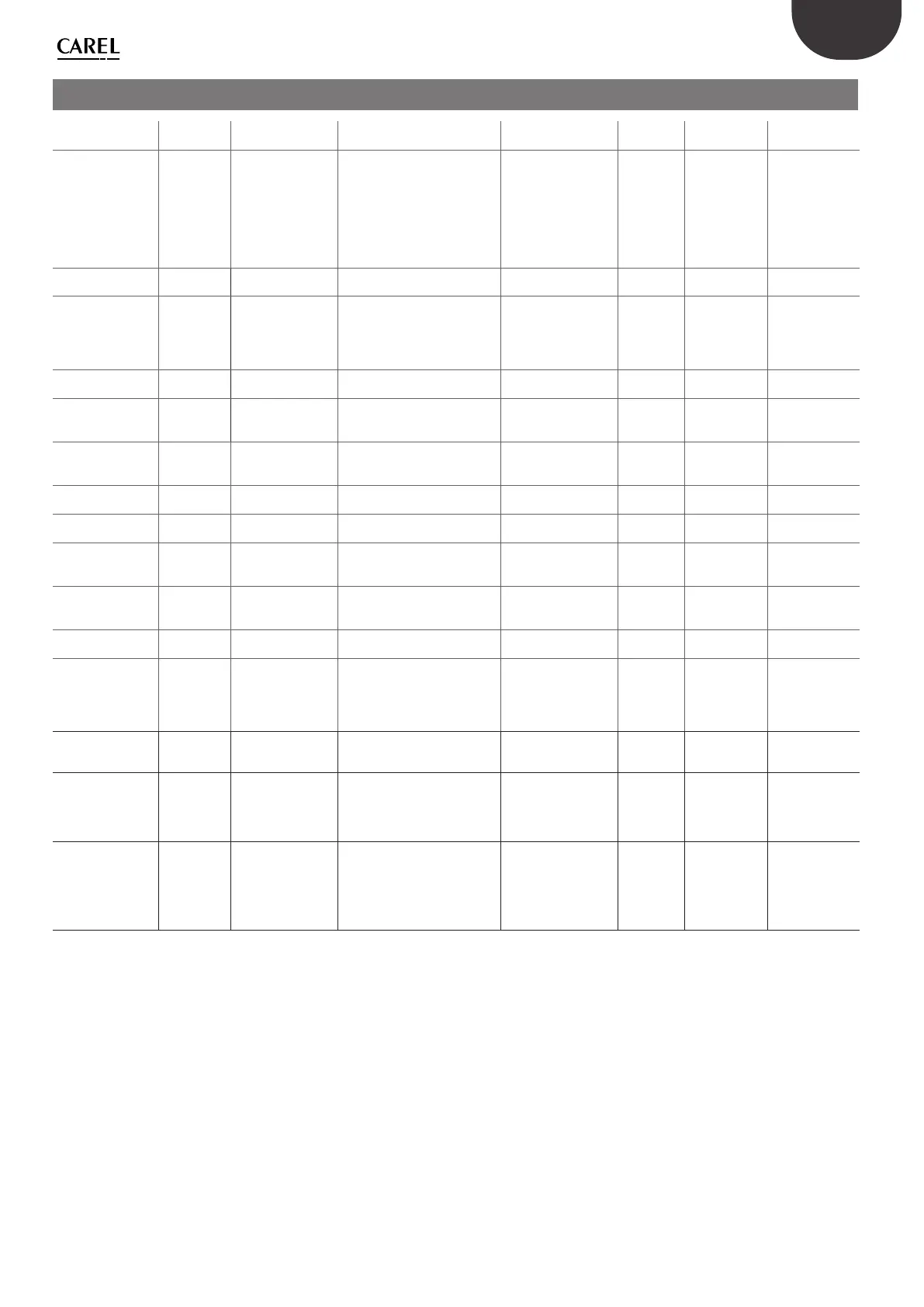

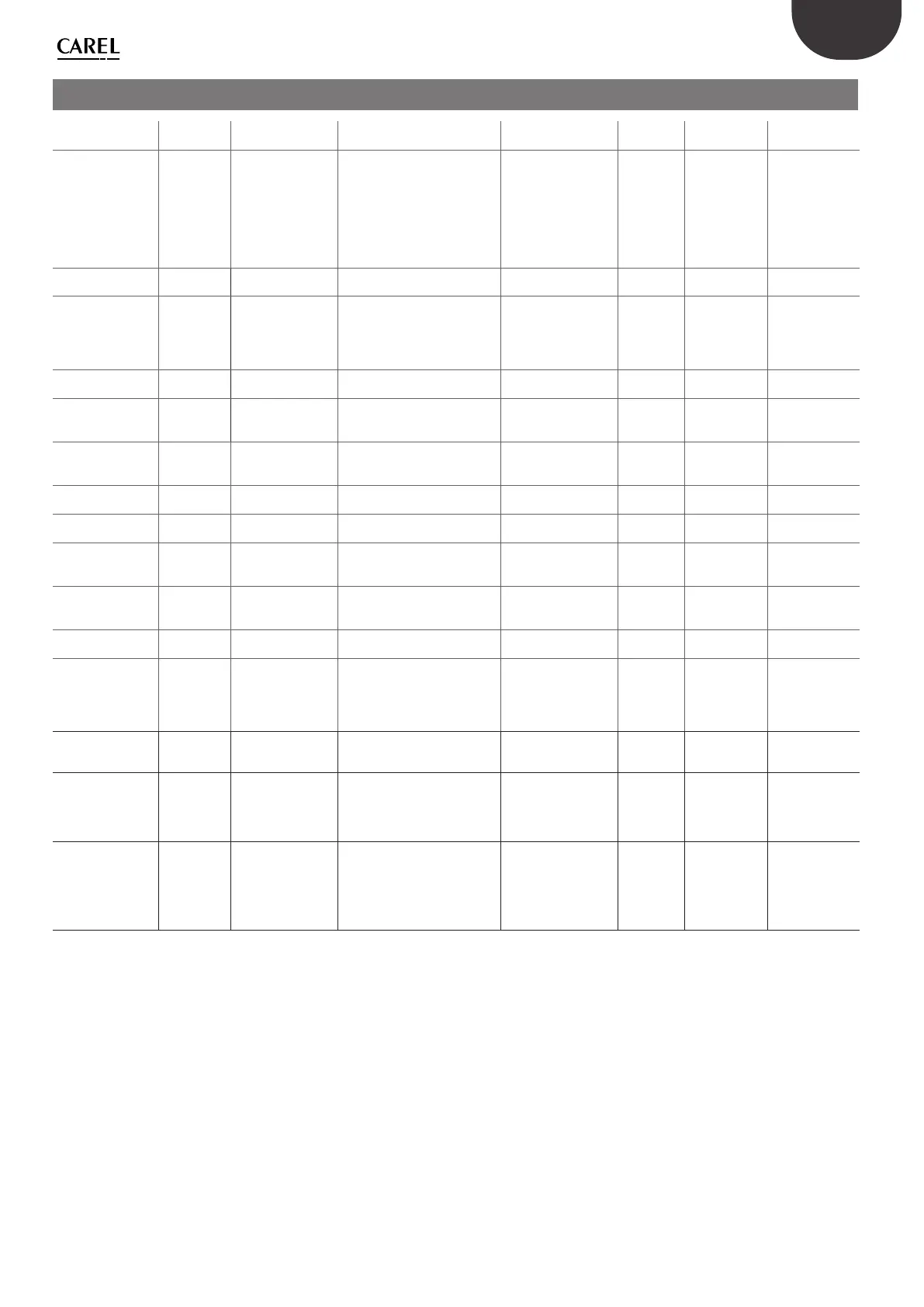

12. ALARMS

red LED signal (*) display code meaning cause solution alarm relay

activation

action reset

2 fast ashes Et Autotest failed - Fill not connected or insuf-

cient

- drain open

- faulty oat

Check:

• water supply and

ll valve;

• blockage of lter on

ll solenoid valve;

• check drain

solenoid valve and

drain connection;

yes humidication

interrupted

ESC / Digital 29

5 fast ashes EP No production Malfunction of piezoelectric

transducers

Carry out maintenan-

ce on tank

yes humidication

interrupted

ESC / Digital 29

3 fast ashes EF No water Interruption to water supply or

ll solenoid valve malfunction

Check:

• water supply and

ll valve;

• blockage of lter on

ll solenoid valve

yes

(in the 10

min. waiting

period)

humidication

interrupted

only per 10

minutes

automatic (after

10 minute wait,

see Chap. 9.5)

4 fast ashes Ed No drain Drain solenoid valve/circuit

malfunction

Check drain valve and

drain connection

yes humidication

interrupted

ESC / Digital 29

5 slow ashes CL Tank maintenance

request signal

b5 operating hours for

recommended maintenance

exceeded

Carry out mainte-

nance on tank and

transducers (cap. 13)

no signal only Reset hour

counter (See

Chap 7.5 or 8.8)

6 fast ashes PU External control si-

gnal not connected

correctly

Cable interrupted/discon-

nected/not connected

correctly.

Check the reference

signal (4 to 20 mA or 2

to 10V).

yes humidication

interrupted

AUTO

2 slow ashes H^ High humidity The signal from the probe indi-

cates humidity above 80%rH

Check humidity probe

signal/cable

yes humidication

interrupted

AUTO

3 slow ashes H_ Low humidity The signal from the probe indi-

cates humidity less than 20%rH

Check humidity probe

signal/cable

yes humidication

interrupted

AUTO

4 slow ashes EE EEPROM alarm Problems in the EEPROM If the problem persists,

contact the CAREL

service centre

yes humidication

interrupted

If this persists

contact service

1 fast ash E0 Functional test not

performed

Functional test not performed

by manufacturer/EEPROM

problems

If the problem persists,

contact the CAREL

service centre

yes humidication

interrupted

If this persists

contact service

7 slow ashes OFL Main Oine Loss of connection from the

serial main (If D37=1)

Check state of the

Main / Cable

yes humidication

interrupted

AUTO

8 fast ash EL Water level alarm Level too high during atomised

water production due to:

• ll SV leak

• transducer malfunction

• fan malfunction

Check:

• ll SV

• transducers

• fans

yes humidication

interrupted

AUTO

6 slow ashes ES1

ES2

ES3

Alarm on secondary

unit 1/2/3

Display secondary unit from

terminal for details of the alarm

see specic alarm

code, chapter “Network

connection”

yes signal only AUTO

1 slow ash -bu Backup unit not

available

The backup unit is o or has an

alarm: contact J17 on the main

unit is open

Check the connection

from the alarm relay

on the backup unit to

input J17 on the main

unit.

no signal only AUTO

9 fast ashes EtL End of piezoelectric

transducer life

The unit has reached AF

working hours (default 9999 h)

Replace the

piezoelectric

transducers to

guarantee rated unit

production

yes signal only Reset internal

piezoelectric

transducer coun-

ter by setting

parameter d6 to

zero (See 8.8)

Tab. 12.a

To reset the alarms, press ESC once to mute the buzzer, press ESC a second time to completely reset the alarm.

(*) Fast ash: 0.2 seconds ON and 0.2 seconds OFF

Slow ash: 1 second ON and 1 second OFF

Loading...

Loading...