45

ENG

“UE BASIC” +03U0042EN - rel. 1.3 - 10 May 2013

12. ADVANCED FUNCTIONS

12.1 Operating principle

Immersed electrode humidifi ers manufacture steam by boiling the water

contained inside the cylinder. The heat required to boil the water is

produced by passing an electrical current through the cylinder. This is done

by applying a voltage to the electrodes immersed in the water.

Initially, when the cylinder is new or has just been cleaned, the current

depends almost exclusively on the type of supply water: the more salts in the

water, the higher the current, and the required steam production is achieved

quicker. Over time the salt deposits in the cylinder increase (these do not

evaporate with the water), helping achieve the rated production. In steady

operation, the level of production required is maintained automatically by

controlling the current input, adjusting the level of water in the cylinder.

The salts that deposit over time cause the progressive depletion of the

cylinder. To avoid excessive accumulation, the humidifi er automatically

drains and replenishes a certain quantity of water at set intervals.

12.2 Control principles

ON/OFF control

The action is all or nothing, activated by an external contact that consequently

determines the control set point and diff erential.

The external contact may be a humidistat, whose status determines the

operation of the humidifi er:

• contact closed: the humidifi er produces steam if the remote ON/OFF

contact is also closed;

• contact open: the production of steam ends.

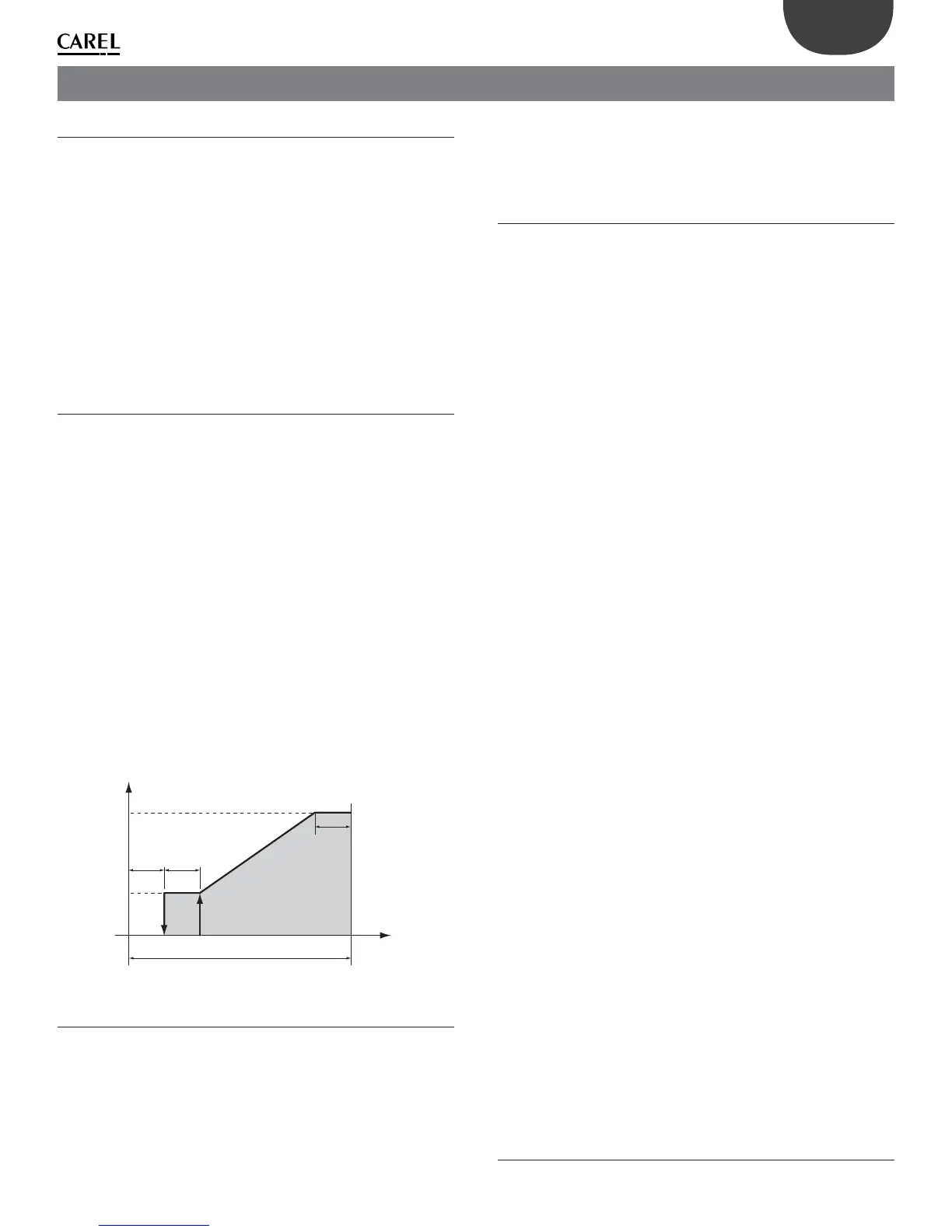

Proportional control

The production of steam is proportional to the value of a signal “Y” from an

external device. The type of signal can be selected between the following

standards: 0 to 10 Vdc, 2 to 10 Vdc, 0 to 20 mA, 4 to 20 mA.

The entire range is indicated as the proportional band. The maximum

production of the humidifi er, corresponding to the value maximum of

the external signal, can be set from 20% to 100% of the rated value of the

humidifi er (parameter P0).

The minimum production has an activation hysteresis, hy, equal to 5% of the

proportional band of the external signal “Y”.

ONOFF

hy

hy

hy

Banda Proporzionale / Proportional Band

P0

Pmin =

20%

Y

%

Produzione di vapore

Steam production

Fig. 12.a

12.3 Supply water conductivity

Conductivity measurement and alarms

The conductivity of the supply water is measured by the conductivity meter

when the fi ll solenoid valve is opened.

Two programmable alarm thresholds are available:

• b5: warning threshold (signal only without activating the alarm relay,

automatic reset when the condition is no longer present);

• b6: alarm threshold (unit shutdown with activation of the alarm relay).

The alarm is activated when the reading exceeds one of the two thresholds

continuously for 60 minutes, or alternatively instantly if the value read is 3

times higher than the threshold.

To disable the alarm signal, simply set the thresholds above the maximum

value of the reading.

12.4 Automatic draining

The humidifi er automatically drains and replaces some of the water

contained in the cylinder, to prevent an excessive concentration of salts

following the evaporation process.

The drain pump is opened for a set time whenever the conductivity exceeds

the maximum limit; this situation is measured indirectly by evaluating the

evaporation speed.

During the automatic draining phase, the electrodes are off , so as to prevent

the drain water from carrying current (the display shows “dr”).

Drain due to excess foam

With certain types of supply water, foam may form during the production

of steam just above the water. This situation must be resolved, as it may

cause water to be released together with the steam. For this purpose, two

electrodes are fi tted on the top of the cylinder. When these electrodes

detect the presence of foam, the humidifi er activates a series of repeated

drain cycles. If the situation persists, the complete washing of the cylinder

is activated.

Drain due to inactivity

In humidifi er does not operate for an extended time (it remains on but does

not produce steam), the water in the cylinder is drained automatically, to

avoid stagnation and hygiene risks. The inactivity time is set using parameter

“bF” (default 3 days). The function can be disabled by setting parameter b1

( see paragraph 11.6).

Powered draining

When running an automatic drain cycle due to excessive salt, the electrodes

are not powered and the production of steam is thus reduced. To keep the

electrodes powered during the drain cycle set parameter b1 ( see paragraph

11.6).

Draining due to a signi cant reduction in the request for

production

In the event of a signifi cant reduction in the request for steam production, the

humidifi er, rather than wait for the level of water (and thus the production)

to decrease due to the eff ect of the production itself, performs a drain cycle.

The reduction in the request for steam production is considered signifi cant

if the current is 33% higher than that relating to the requested level. This

function can be disabled.

Set parameter b1 ( see paragraph 11.6)

Periodical drain

When using water rich in substances such as humus and lime, a periodical

drain cycle should be set for the cylinder to avoid accumulating residues.

To enable the periodical drain, set parameter b1 to 64. In this way, every

24 h the humidifi er will drain all the stagnant water in the cylinder, and

the display will show code “dP” (periodical drain). If the periodical drain is

enabled, the number of hours between two periodical drain cycles can be

set using parameter “bE”.

Note:

For the manual drain function, see chap. 6, for the mechanical drain see

paragraph 9.4.

Loading...

Loading...