16

pGD Touch +030221540 rel. 1.1 - 21.01.2015

ENG

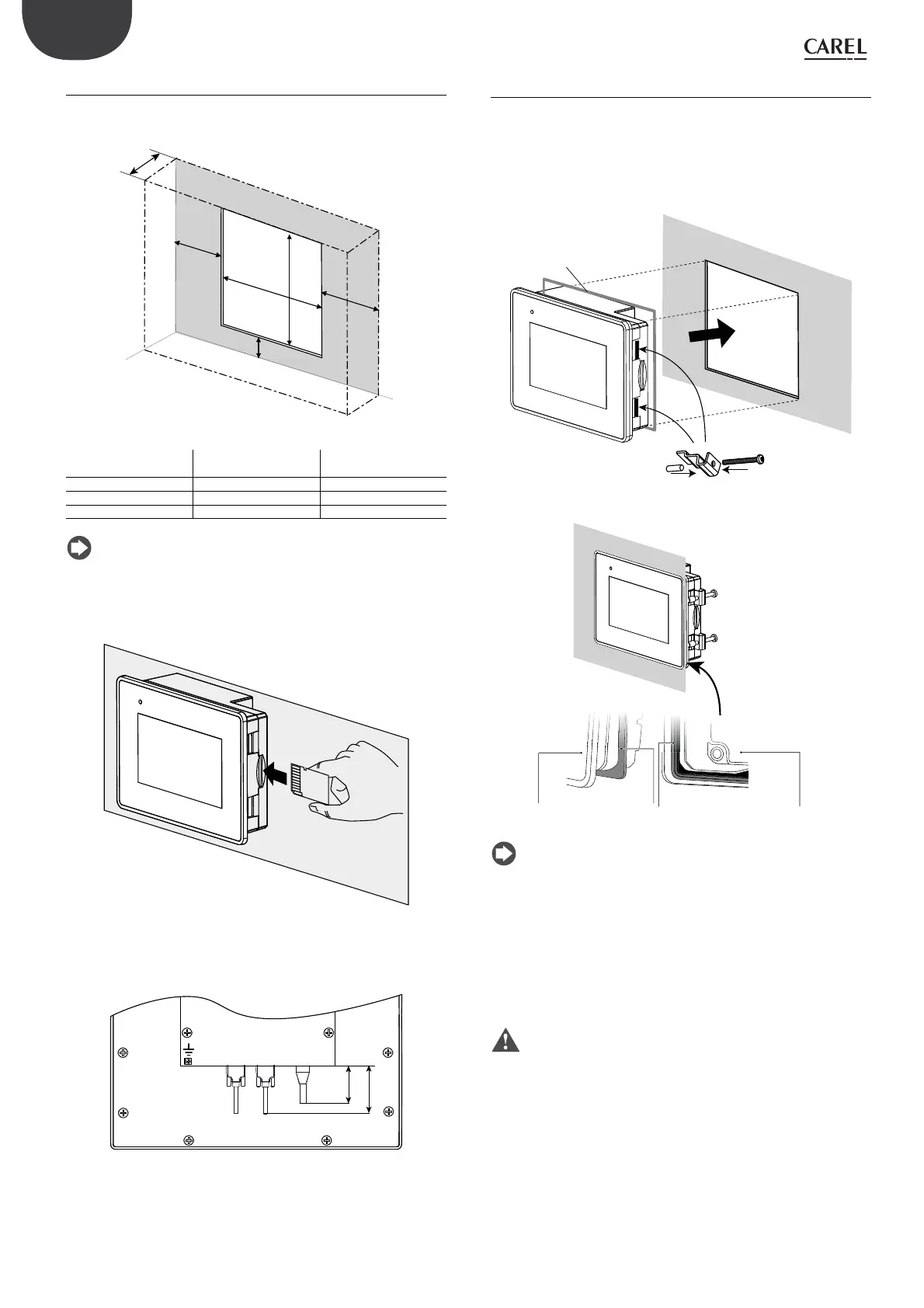

4.3.3 Drilling template and minimum distances

The drilling template used for assembly must have the dimensions

shown in the figure.

w

z

a

b

c

d

Fig. 4.b

Size w (mm) z (mm)

4,3” 136 96

7” 176 136

10” 276 (10.86”) 221 (8.7”)

13” 326 (12.83”) 256 (10.07”)

Tab. 4.c

Note: leave minimum clearance around the terminal (a, b, c, d) so

as to:

1. allow ventilation;

2. temporarily access the device to insert and remove a USB pendrive

or SD card;

Fig. 4.c

3. keep in mind the space occupied by cables and connectors

(distances in mm)

AUX

PLC PC/PRINTER ETHERNET USB

40

100

Fig. 4.d

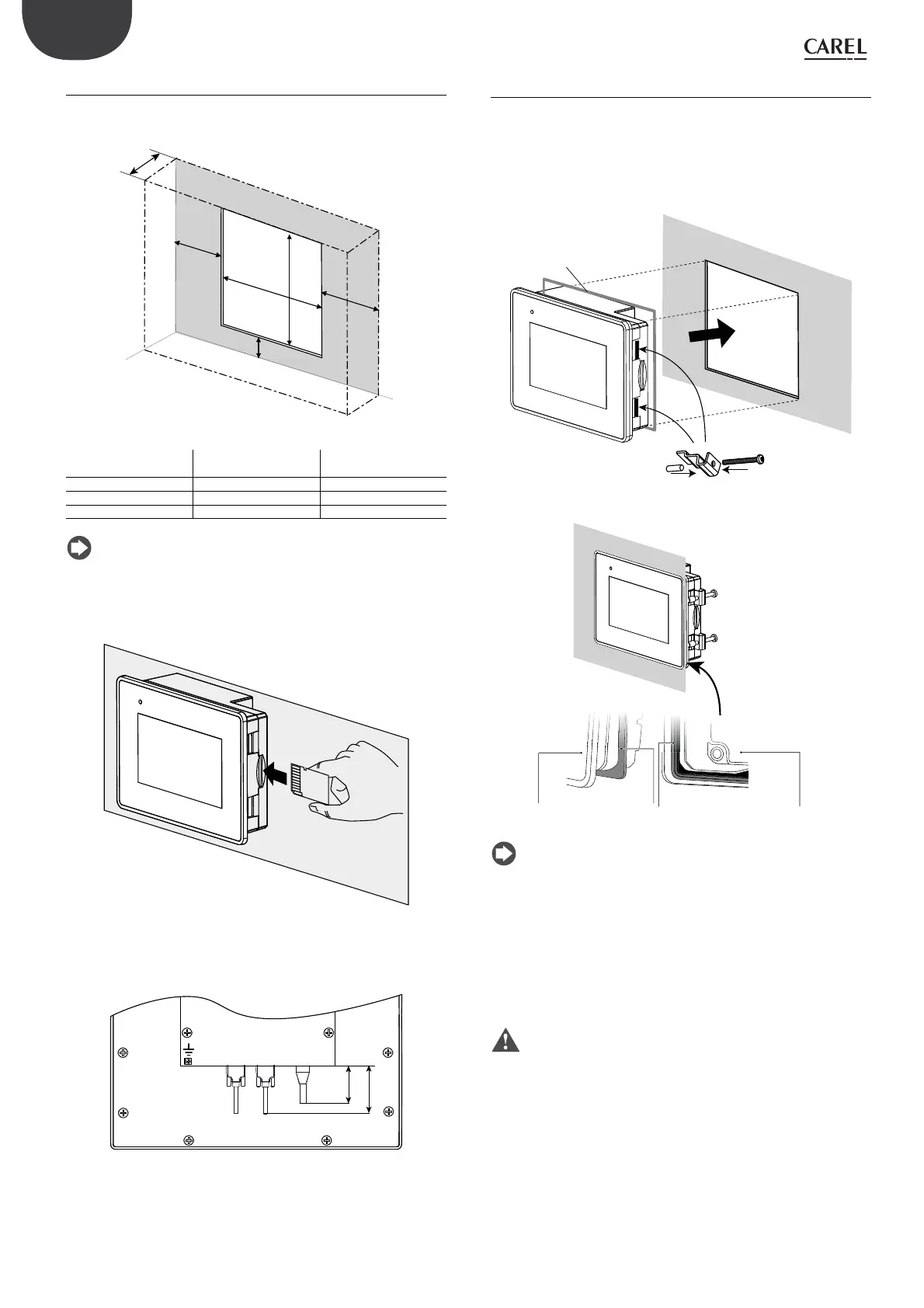

4.4 Assembly

Make a rectangular opening as shown in the previous paragraph.

Procedure:

1. insert the gasket (see the figure for the 4.3” and 7” models);

2. place the terminal in the opening;

3. tighten all the screws on the fastening clips until the end of the nut

touches the panel.

1

3

2

Fig. 4.e

display

guarnizione lato liscio

flat side gasket

guarnizione lato a righe

striped side gasket

retro display

rear display

Fig. 4.f

Note:

• the thickness of the electrical panel sheet metal (or other material)

must be suitable to ensure safe and stable terminal assembly;

• the pressure exerted by the fastening clips must not deform the sheet

metal, so as to ensure the protection rating (IP) shown in the table of

technical specifications;

• insert the fastening clips so as to ensure uniform pressure of the

terminal on the panel and consequently the specified protection

rating (IP).

Important: front IP65 protection rating is only guaranteed if are

the following conditions have been met:

1. maximum deviation of the drilling template from the flat surface: ≤

0.5 mm;

2. electrical panel sheet metal thickness: 1.5 to 6 mm;

3. maximum roughness of the surface where the gasket is applied: ≤

120 μm.

Loading...

Loading...