11

Models C708/C709/C716/C717

Introduction

Running Specifications

Pressures/Temperatures

The following are the Taylor Company

recommended settings for various components

within these models. The freezers in this manual use

refrigerant R404A.

Note: These settings apply to both sides of the

C716 and C717.

EPR Valve = 60 psi (414 kPa)

DBV Valve = 10 - 11 psi (69 - 76 kPa)

OPR Valve = 40 psi (276 kPa)

Expansion Valve (AXV)

Air Cooled - 21 psi (145 kPa)

Water Cooled - 21 psi (145 kPa)

for a normal product of 16° to 18°F (-8.8° to -7.7°C).

Expansion Valve Adjustment (AXV)

Place your gauge on the access valve on the suction

line (located at the compressor).

Adjust higher or lower by turning the adjustment

screw. Clockwise turns raise the pressure and

counterclockwise lower the pressure.

Note: Make expansion valve adjustments with mix

in the cylinder and the freezer in the AUTO mode.

Be sure to allow adequate time for the pressure to

stabilize.

Low Side (Suction)

Suction pressure equals expansion valve setting.

High Side (Discharge)

High side pressure varies for air cooled units,

depending on the ambient temperature.

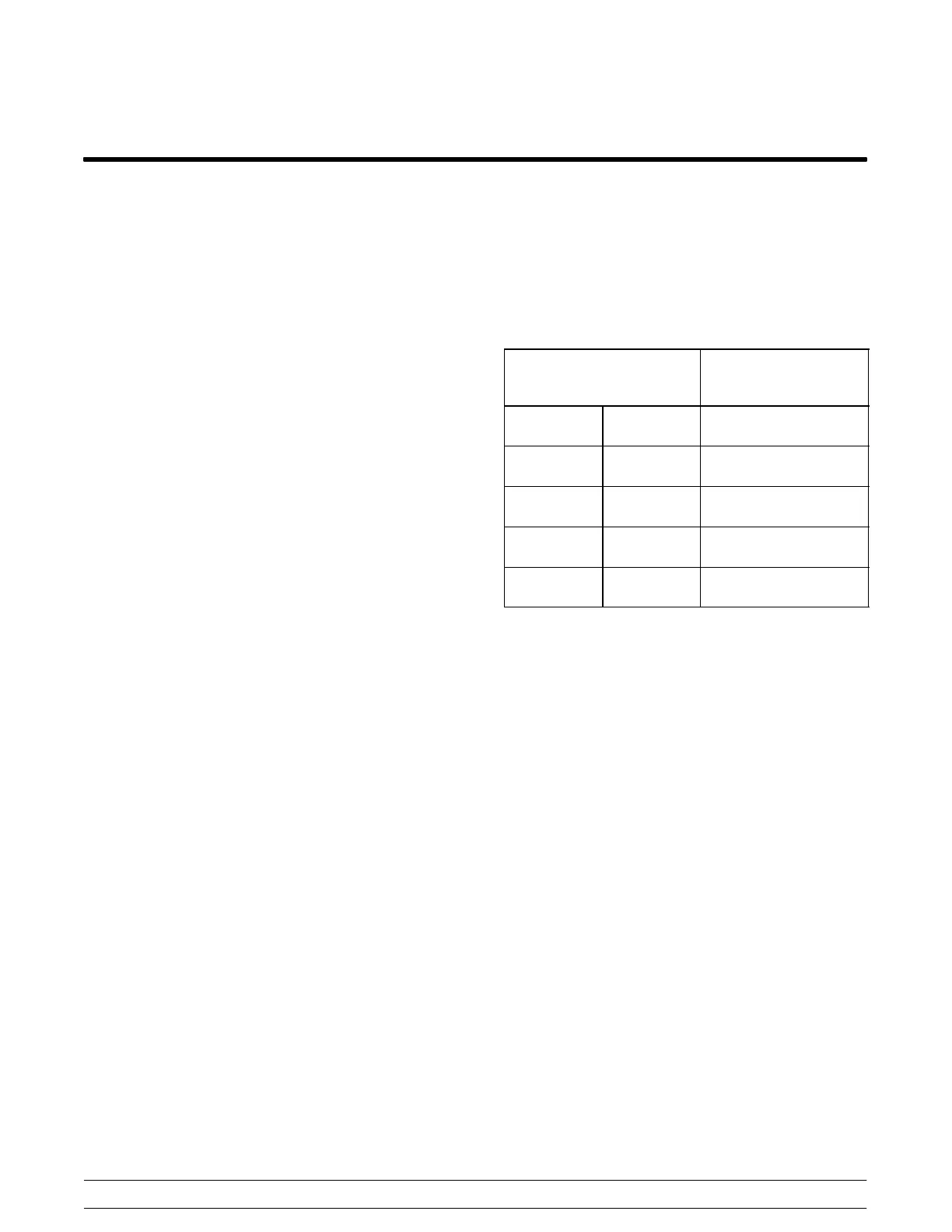

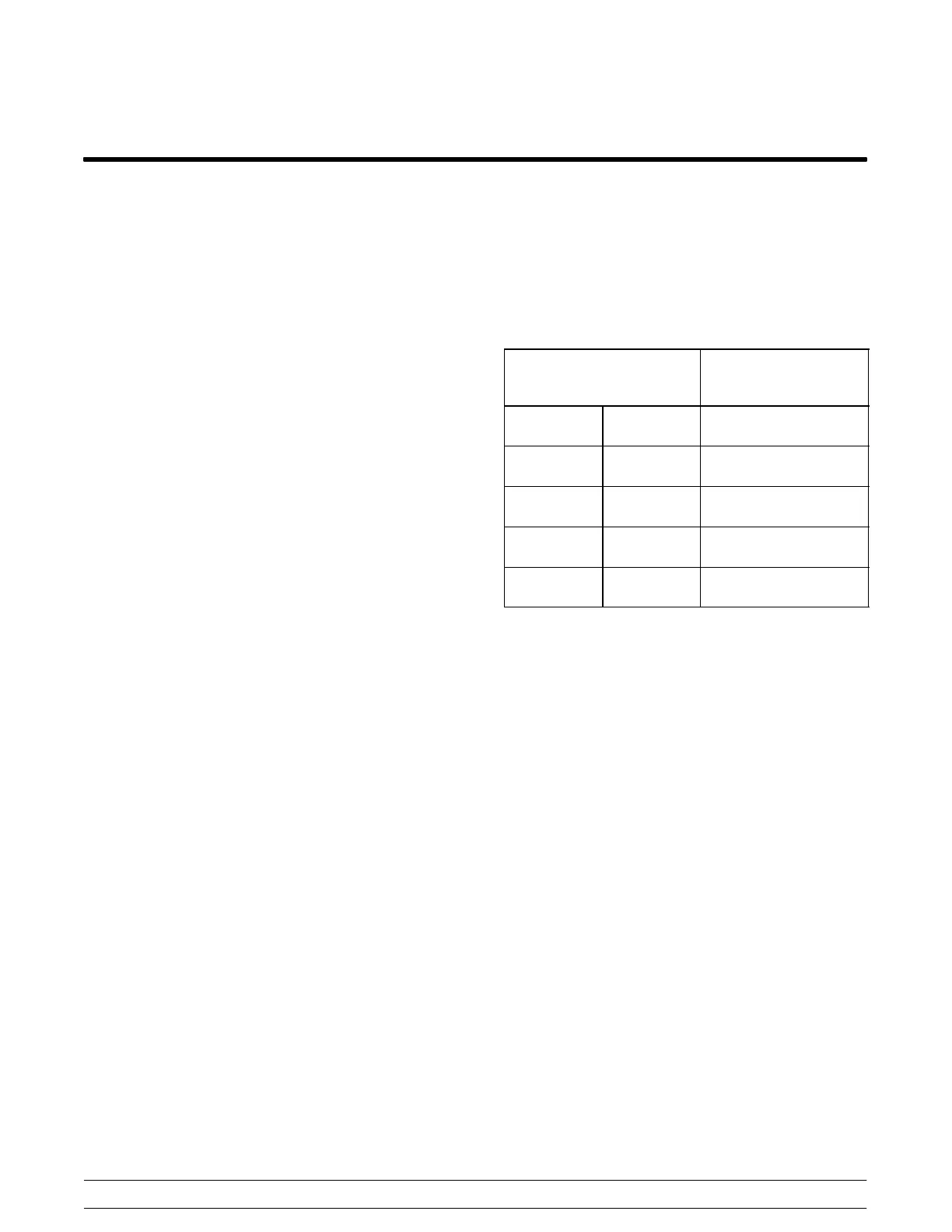

Ambient Temperature Normal Operating Head

Pressures

F C PSI

70° 21.1° 240 - 270

(1,655 - 1,862 kPa)

80° 26.7° 270 - 300

(1,862 - 2,069 kPa)

90° 32.2° 300 - 340

(2,069 - 2,344 kPa)

100° 37.8° 340 - 380

(2,344 - 2,620 kPa)

Water Valve

On a water cooled unit, the water valve should be

set to maintain a compressor head pressure of 255

PSI (1,758 kPa).

Water Valve Adjustment

Place your gauge on the high side access port of the

compressor. Turning the adjustment stem on the

water valve clockwise will lower the pressure.

Note: Make this adjustment with mix in the cylinder

and the freezer in the AUTO mode. Be sure to allow

adequate time for pressure to stabilize.

Loading...

Loading...