CHAPTER 6 – LUBRICATION / FILTERS / FLUIDS

6-28

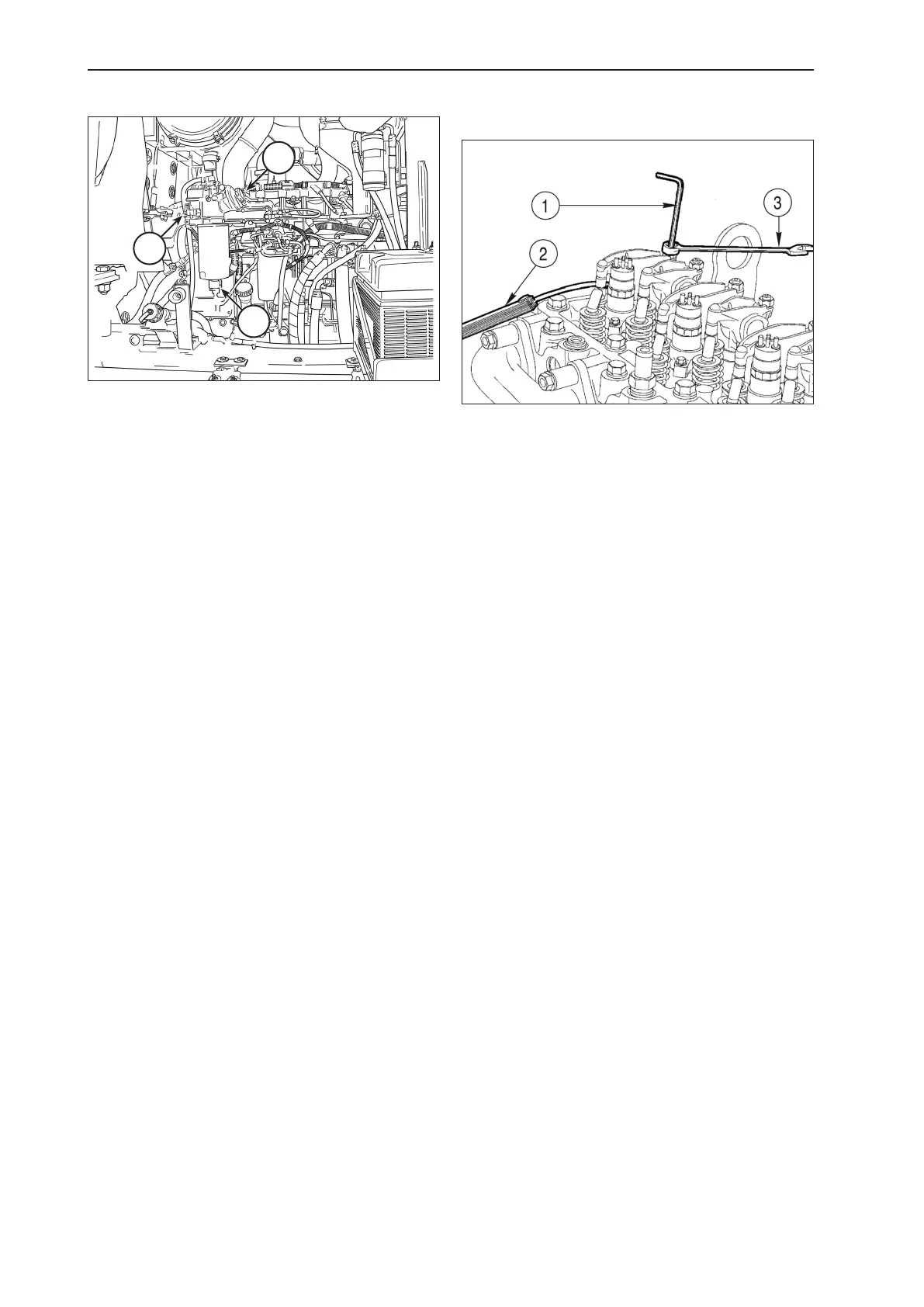

Adjusting Engine Valves

Verify each 1000 hours

VALVE CLEARANCE

Adjust the clearance between the rockers and valves

using a Allen tools kit (1), a wrench tool (3) and a feeler

gauge (2).

Always adjust the valve clearance with engine cold, that

is, with engine coolant temperature below 140ºF (60°C).

First determine the top dead center (TDC) on engine nº 1

cylinder. To perform so, rotate the crankshaft slowly, using

the adapter and gear of the manual rotating tool. Install

the synchronizing pin and adjust the following valves: 1A,

1E, 2A, 3E, 4A, 5E. Remove the synchronizing pin, rotate

the crankshaft 360° and install again the synchronizing

pin. Perform the adjustment of the following valves: 2E,

3A, 4E, 5A, 6A, 6E. Clearance of valves must meet the

specications of table below

Valve clearance with engine cold:

Intake ........................ 0.20 – 0.30 mm (0.008 – 0.012 in)

Exhaust ..................... 0.46 – 0.56 mm (0.018 – 0.022 in)

NOTE: The clearance will be correct when the feeler gau-

ge is passed between the valve rod and the rocker, with

a little resistance.

Fuel System Air Bleed

1

2

3

BLEEDER SCREW1.

DRAIN BOLT2.

PUMPING KNOB3.

Clean the area around the separator lter head to 1.

avoid contamination.

Completely loose the aluminum bleeder screw (1) lo-2.

cated on the lter head.

Be sure that the drain bolt (2) on the lower part of the 3.

lter is completely tight.

Prime the knob (3) until the Diesel fuel comes out 4.

through the bleeder screw (1).

Tight the bleeding bolt (1).5.

Loading...

Loading...