CHAPTER 8 – ELECTRICAL SYSTEM

8-7

845B / 865B / 885B with FUNK Transmission

Before performing any welding work on the machine, turn

off the ignition switch, making sure to place it to the “OFF”

position. Connect the ground cable of the welding equip-

ment to a maximum distance of 0,6 m (2 ft) from the part

being welded.

For a safe welding procedure performance, some electro-

nic component connectors must be disconnected. Make

sure to disconnect the connectors listed below:

X23

X24

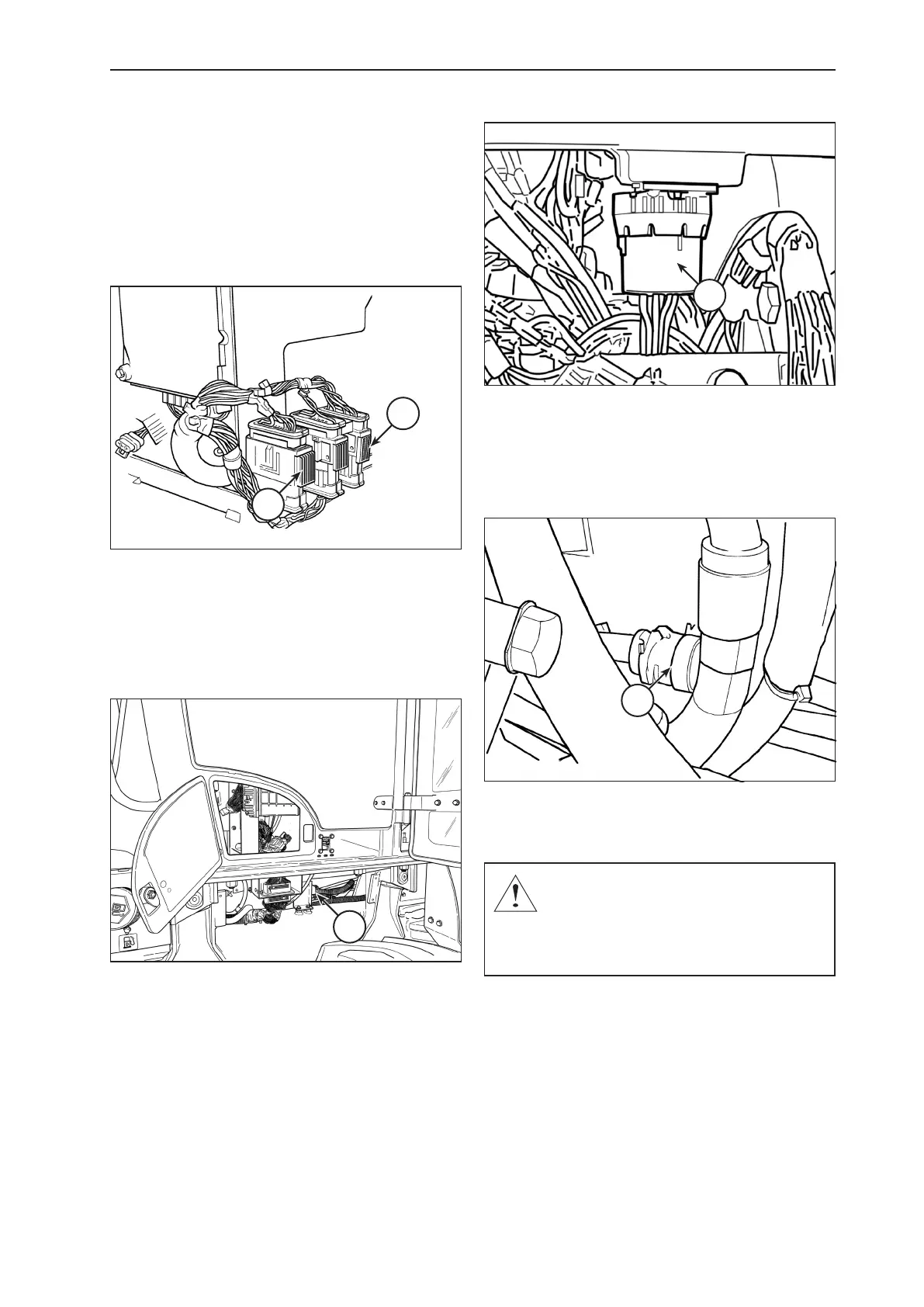

X23 – TCU GRAY CONNECTOR

X24 – TCU BLACK CONNECTOR

Transmission control module (TCU) – On the right

side of the operator cabin, 3 transmission control module

connectors are located. Make sure to disconnect the X24

black connector and the X23 gray connector.

X6

X6 – LATERAL PANEL CONNECTOR

Front panel – Disconnect the 70-pin X6 connector from

the front panel, located on the right hand-side of the rear

chassis, between the cabin mounting brackets. To discon-

nect, loosen the center screw on the connector using a 4

mm Allen wrench.

J4

J4 – FUNK TRANSMISSION SELECTOR LEVER CONNECTOR

Transmission selector lever – Disconnect the J4 con-

nector from the selector lever, located on the right side

console, above the fuse boxes and below the transmis-

sion gearshift selector lever itself.

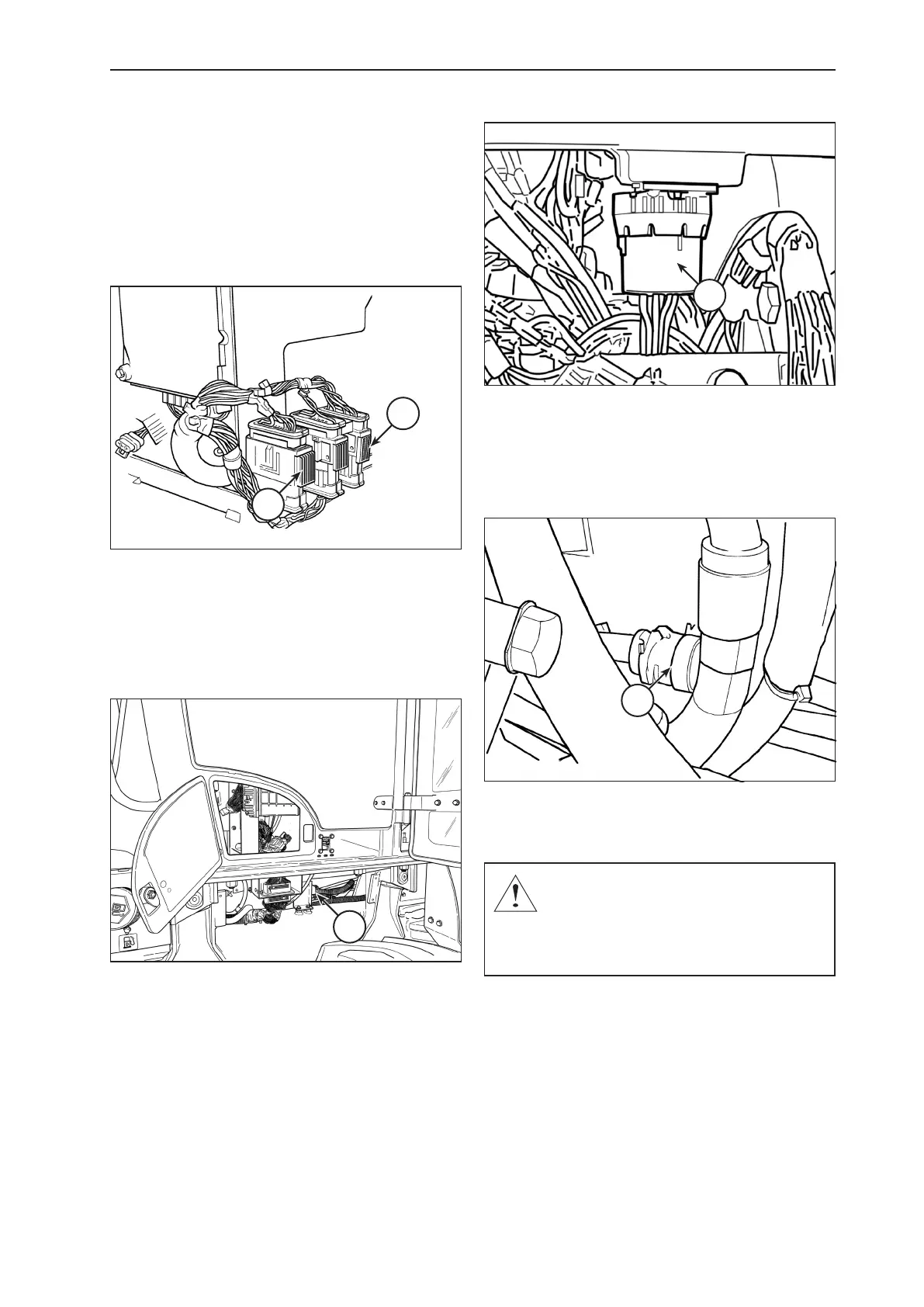

J6

Transmission – Disconnect the J6 connector , located

on the left hand-side of the machine, next to the trans-

mission.

CAUTION: If a welding work is performed wi-

thout disconnecting the above described con-

nectors, irreparable damages may occur to the

control module, to the transmission and to the

front panel of the machine.

Loading...

Loading...