Installation

2-8

750-382

CBT

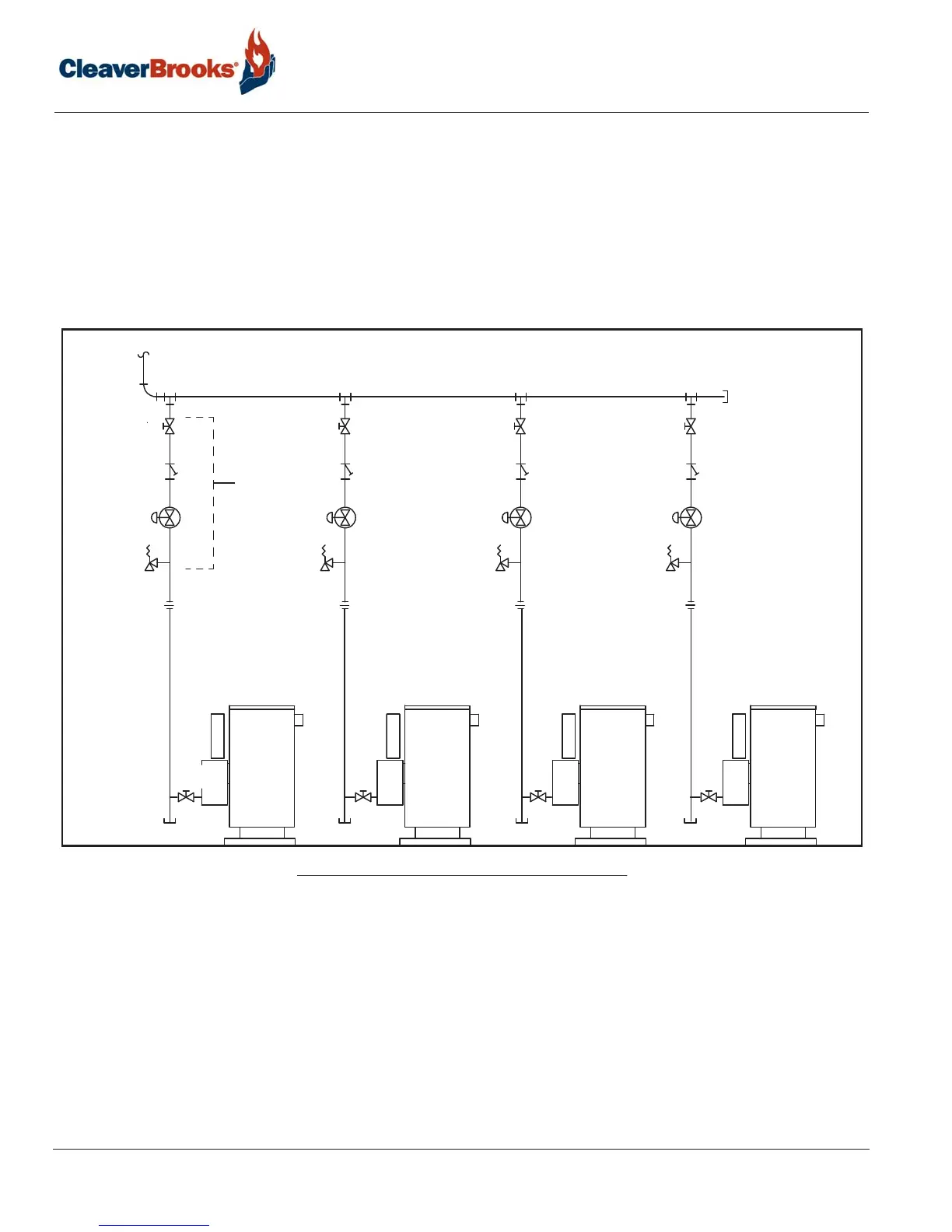

Gas header - For multiple unit installations, a single common gas header is recommended with individual

takeoffs for each boiler (See Figure 2-4). Boiler gas manifold piping should be sized based on volume

requirements and lengths between each boiler and the fuel main header. Tables 2-6 through 2-10 indicate the

proper sizing for multiple units of equal size, placed on the factory standard center with the indicated take off

size. For installations with a mixed sized use, determine the flow of each unit and total the input. With the total

input, find length of run from the source and determine what size header will be needed for the flow of all units

firing. Pipe sizes are based on Table 2-4 with boiler gas line take-off at 20 feet from the header. If pipe runs are

greater or if gas pressure is different, refer to Tables 2-4 and 2-5 for pipe sizing. Main fuel supply header should

be sized for <4" w.c. pressure drop with all equipment operating at 100% capacity.

FIGURE 2-4. Typical gas piping - Example 1

MANUAL

SHUTOFF

DRIP LEG

MANUAL SHUTOFF

GAS STRAINER

REGULATOR

SEE NOTE 1

RELIEF VALVE

SEE NOTE 5

OPTIONAL

FROM METER

HEADER PIPE

NOTES:

1. Step-down regulator required

if supply pressure >1/2 psig.

2. Refer to local fuel gas codes when

applicable.

3. Header to be sized for room

capacity.

4. Provision required for measuring

gas supply pressure at boiler.

5. Relief valve required if gas supply

pressure >1 psig.

Loading...

Loading...