Maintenance

5-26

750-382

CBT

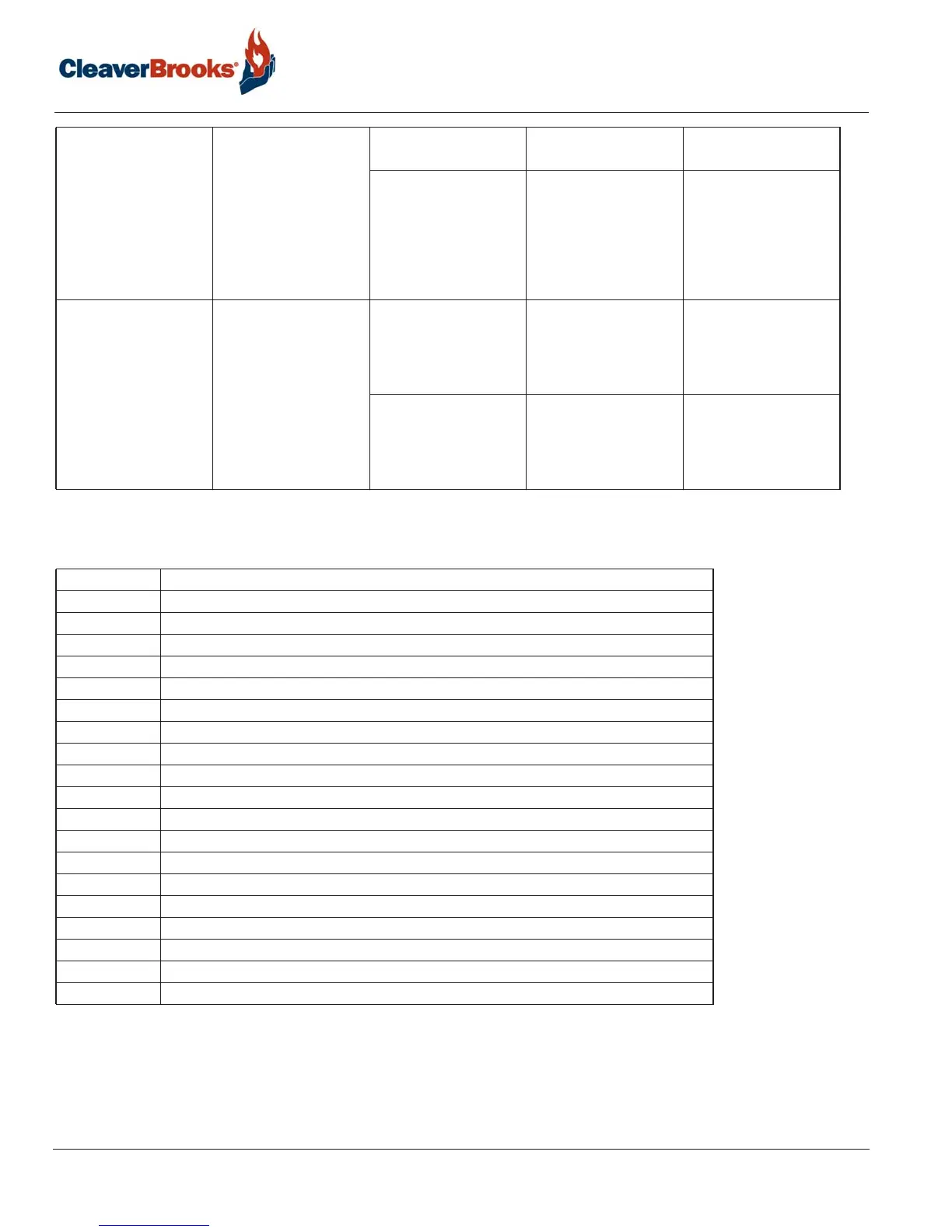

S.2. Anti-short cycle

time is too long

Check anti-short cycle

time

Reduce ant-short cycle

time parameter; set to

0 to disable this func-

tion. Anti-short cycle is

located in the "Steam

Configuration" parame-

ter group.

Boiler cycles on and off

too frequently

T. Demand: Steam

Burner state: Standby

(normal)

T.1. Steam Off hystere-

sis setting is too low

Check Steam Off point

on boiler status screen

Increase the Steam Off

point hysteresis param-

eter setting to allow

boiler to modulate lon-

ger before shutting off.

T.2. PID gains are too

aggressive, or too high

Check P (proportional)

and I (integral) gain

settings.

Reduce the gain values

for both P and I gain.

Observer control of

boiler to meet steam

pressure set point.

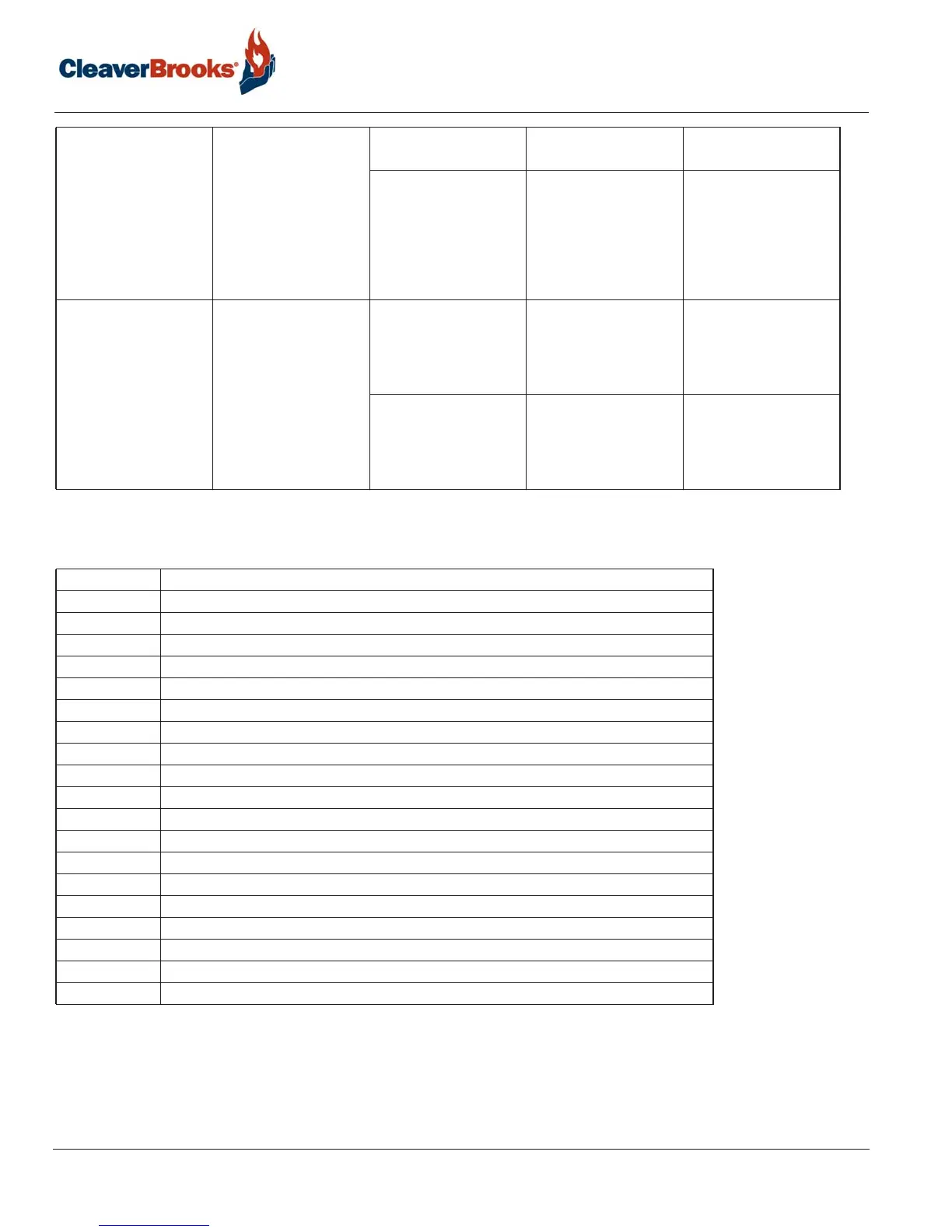

TABLE 5- 2. Common abbreviations

WD Wiring Diagram

ILK Safety InterLock circuit (always require a manual reset)

LCI Limit Control Input circuit (resets automatically)

SP Set Point (steam pressure)

PID Proportional-Integral-Derivative (control method)

SSOV Safety Shut-Off Valve

FW Feed Water

LWCO Low Water Cut-Off

ALWCO Auxiliary Low Water Cut-Off

CAPS Combustion Air Proving Switch

LGPS Low Gas Pressure Switch

HGPS High Gas Pressure Switch

HLC High Limit Control (steam pressure)

OLC Operating Limit Control (steam pressure)

LED Light Emitting Diode (common on solid state controls, such as LWCO)

AC or VAC Alternating Current (electrical power) or Voltage AC

DC or VDC Direct Current (electrical power) or Voltage DC

RPM Revolutions Per Minute (combustion air fan speed or firing rate)

DIN electrical connector type defined by German standards association

UV Ultra-Violet (flame scanner type)

Problem Display Message Possible Cause/Symp-

tom

Diagnostic Check Corrective Measures

Loading...

Loading...