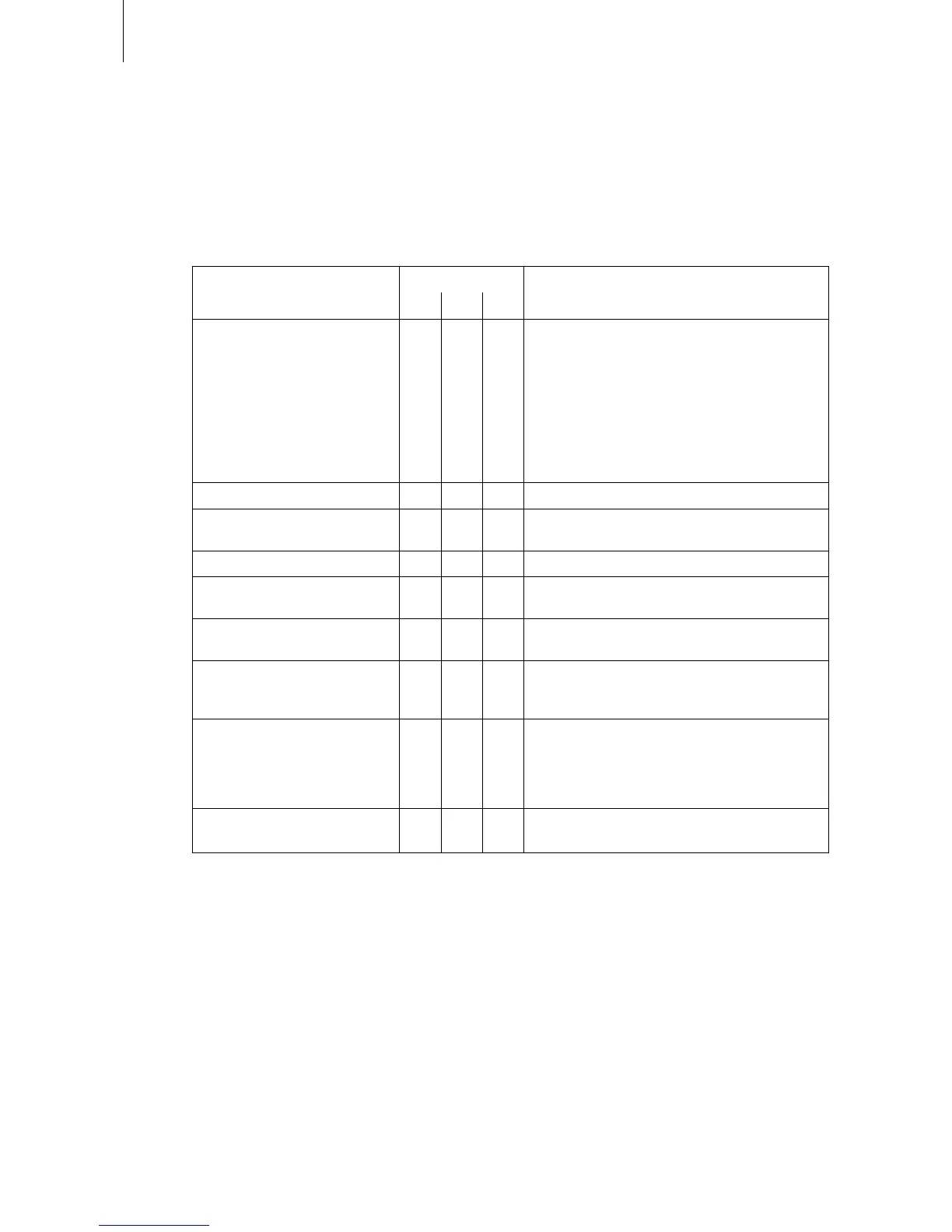

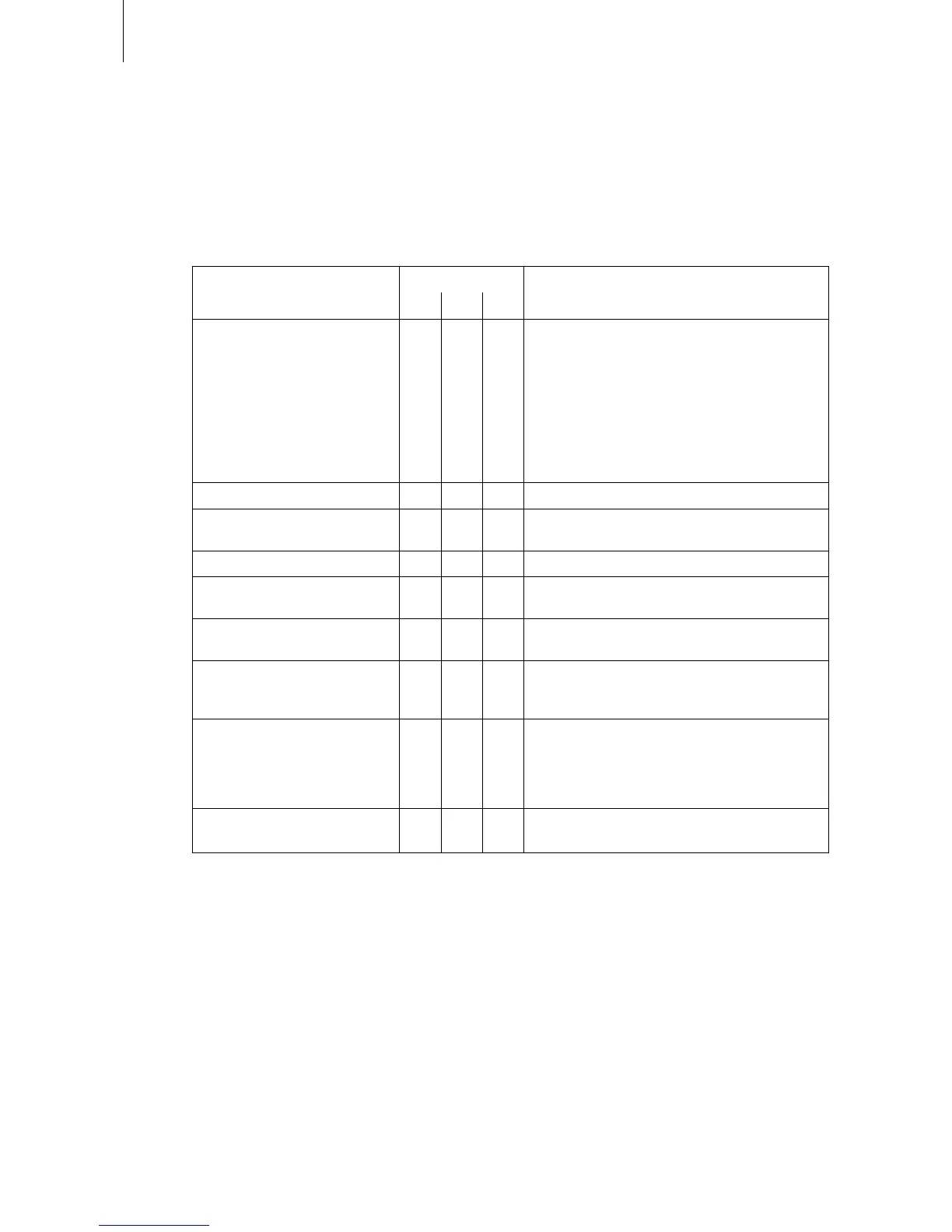

7.2 Maintenance list

TomaintainoperationalsafetytheCondairEL2steamhumidiermustbemaintainedatregularin-

tervals.Thisisdifferentiatedbetweenthefirst maintenance after approx. 500 operating hours (I),

steam cylinder maintenance after the yellow LED lights (II) and annual maintenance (III).

Below you will nd a summary of the work to be carried out for each of the three maintenance

stages.

Components Interval Work to be done

I II III

Cleanable steam cylinder Type

D..

X X X Clean steam cylinder and electrodes and check

fordamage,replaceifnecessary.Note:Thesteam

cylindermustbereplacedafteramaximumoperat-

ingtimeof5,000h.

Electrode plug X X X Checktoseermlypositioned(removecoverand

tighten xing screw with hexagonal head socket

wrench).

Warning! This work should only be carried out by

an electrician.

Replacement steam cyl. type A.. X Remove and replace.

Drainvalve X Remove,disassembleandclean,replaceifneces-

sary.

Steam cylinder receptacle X Inspect,cleanifnecessary.

Inlet valve X Remove and clean lter insert, replace if neces-

sary.

Drainpipeandsiphon X Inspect, clean if necessary (decalcify and rinse

out).

Steam installation X X Inspect steam and condensate hoses for cracks

and to see that they are correctly attached, replace

faultyhoses.

Water installation X X Inspectwater hoses in the unit forcracks and to

seethattheyarecorrectlyattached,replacefaulty

hoses

Checksupplypipeistight,maketightifnecessary.

Cleanwaterlter,

if

available.

Electrical installation X X Checkallcablesintheunitarermlypositionedand

examinestatusofinsulation.

Loading...

Loading...