Helix Operator’s Manual

© 2012-2014,Cornelius Inc. All Rights Reserved - 9 - Publication Number: 621058497OPR

OPERATION

INITIAL SYSTEM PREPARATION

Pressurizing the CO2/Compressed Air System

The Helix unit is designed to operate on a CO2/compressed air input pressure of

0.48-0.83 MPa (70-120 psig). A shutoff valve must be installed in the line to the

Helix unit. Perform the procedure in Table 1 to pressurize the CO

2/compressed air

system.

Pressurizing the Water System

The Helix unit is designed to operate with a water inlet pressure of 0.48-0.83 MPa

(70-120 psig)

Perform the procedure in Ta bl e 2 to verify the water connection to the unit.

The unit must only be connected to a clean, potable water supply.

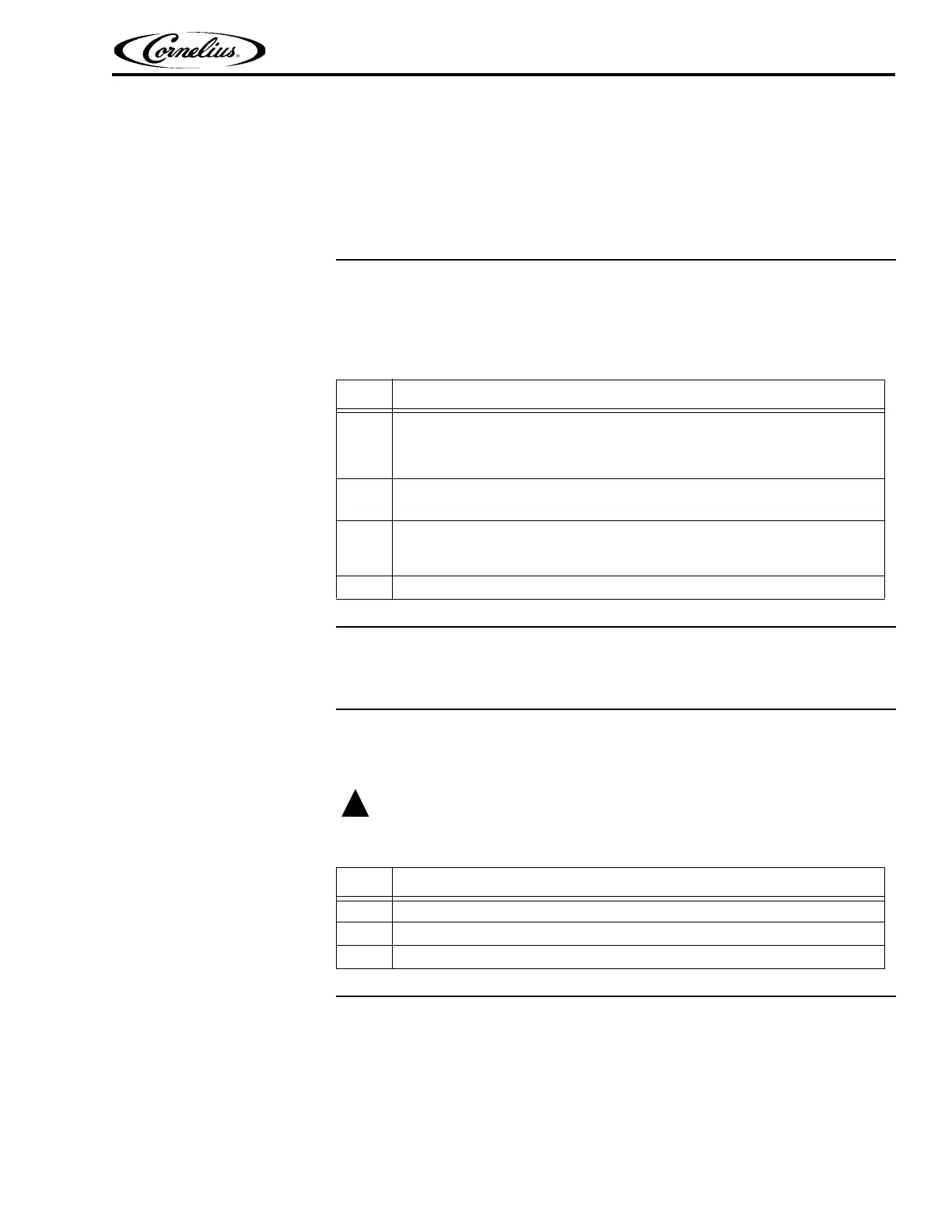

Table 1.

Step Action

1

Open the

CO2/compressed air cylinder valve slightly to allow lines to slowly fill

with gas. When lines are fully pressurized, listen and check for leaks. Open the

CO2/compressed air cylinder valve all the way until it back-seats itself (this pre-

vents leaks from the valve).

2

Adjust the CO2/compressed air cylinder regulator for the unit to between 0.48-

0.83 MPa (70-120 psig) at the unit.

3

Check for

CO2/compressed air leaks by turning off the CO2/compressed air

supply to the unit and listening for leaks. Wait at least 3 minutes and check the

CO2/compressed air cylinder gauge to see if the pressure has dropped.

4 The system is now ready for operation.

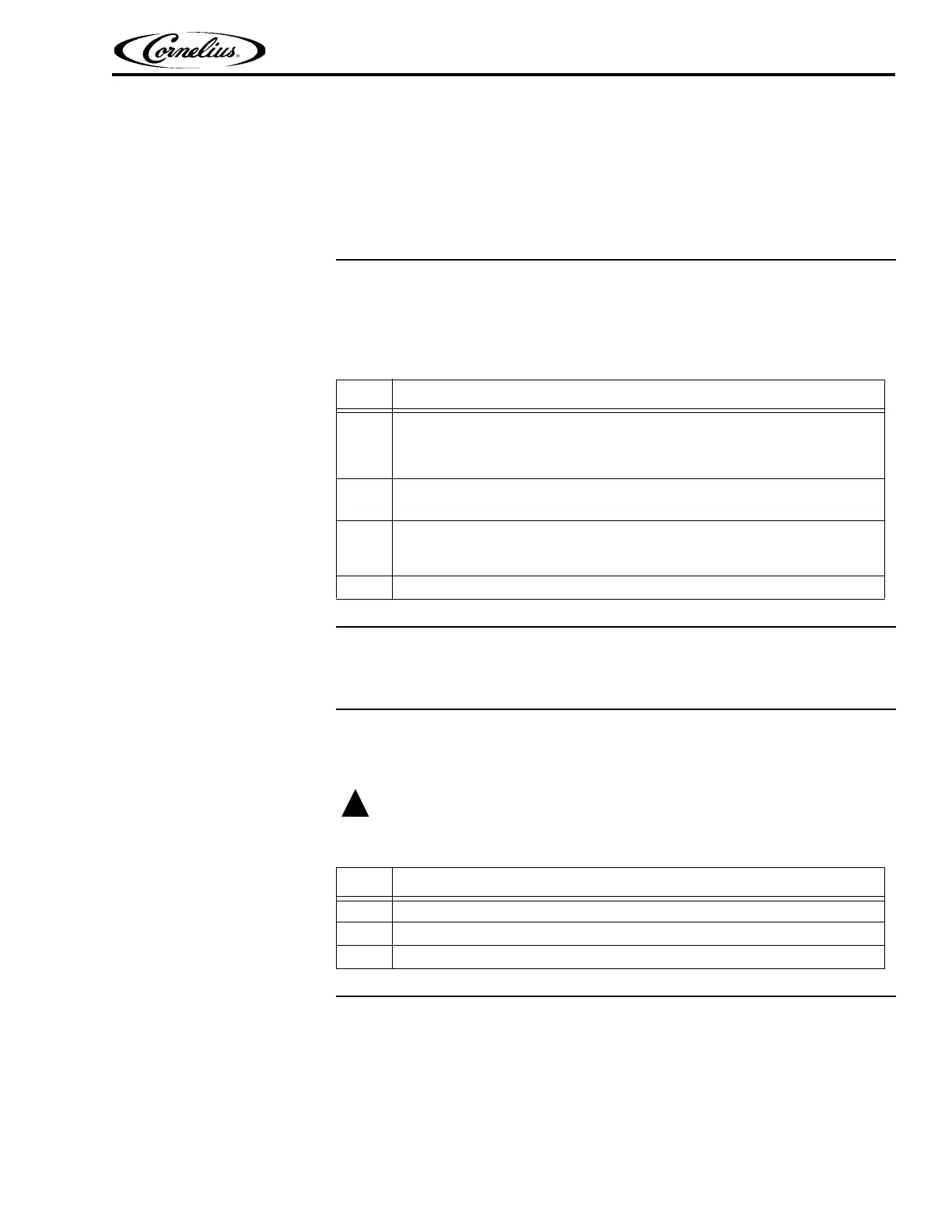

Table 2.

Step Action

1 Turn on the water supply to the unit.

2 Check the system for leaks.

3 The water system is now ready for operation.

Loading...

Loading...