Helix Operator’s Manual

Publication Number: 621058497OPR - 34 - © 2012-2014, Cornelius Inc. All Rights Reserved

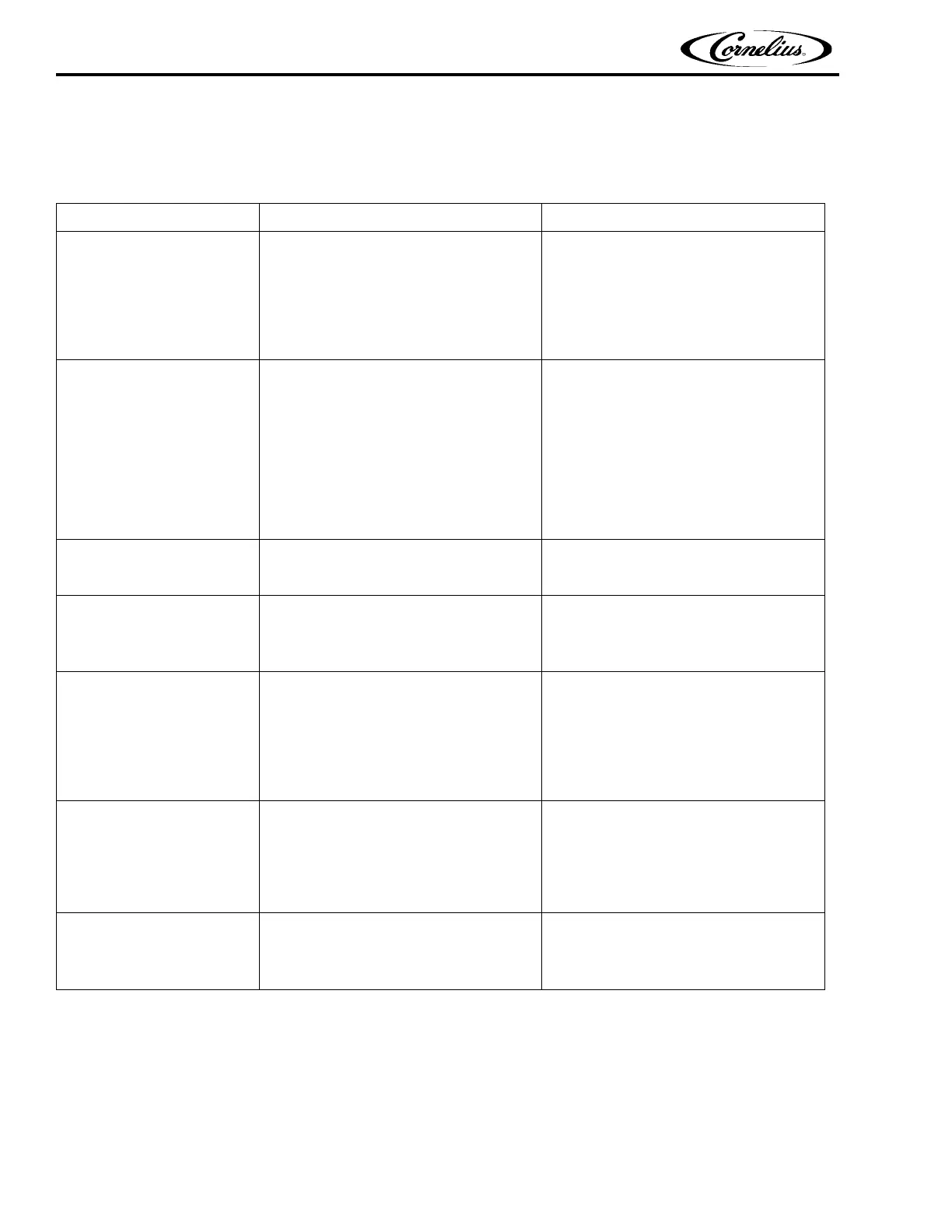

TROUBLESHOOTING

TROUBLESHOOTING - CONTROLS

Problem Probable Cause Remedy

No activity at all

A. Unit unplugged / cable disconnected

B. No power to branch circuit.

C. Keypad bad or disconnected.

D. Control Board bad.

A. Make sure unit is plugged in and cord is

connected in E-box

B. Make sure fuse is good/installed or

breaker is switched to “ON”.

C. Check for proper connection/replace

keypad

D. Replace Control Board

Front panel LEDs indicate

unit on but no motor activ-

ity/will not respond

A. Software detected error condition

B. 24VAC missing

C. Bad or missing cable connection

D. Control Board bad

A. See error table .

B. Check that faceplate is in proper

mounted position and adjust as needed

Check for excessive refrigeration pres-

sure and correct

Check connections and transformer in

E-box and correct

C. Connect or replace cable.

D. Replace Control Board

No condenser fan or com-

pressor

A. Software detected error condition

B. Bad contactor or connections

A. See error table document

B. Check connections, contactor and

transformer in E-box and correct

No condenser fan but com-

pressor runs

A. Bad connections

B. Bad condenser fan

C. Bad contactor

A. Check connections at contactor and fan

and correct

B. Replace

C. Replace

No compressor but con-

denser fan runs

A. Bad connections

B. Bad start relay

C. Bad capacitor(s)

D. Bad compressor

E. Bad contactor

A. Check connections at contactor, capac-

itors, start relay and compressor and

correct

B. Replace

C. Replace

D. Replace

E. Replace

Product Bowl blades do not

turn

A. Blades uncoupled from drive

B. Bad / missing connections to hopper

motor

C. Control Board bad

D. Bad Product Bowl motor

A. Check that hopper product viscosity is

within limits & correct as necessary

B. Check connections & correct as neces-

sary

C. Replace Control Board

D. Replace motor

Product does not dispense

A. Motor does not turn

B. Bad connections to dispense switch

C. Dispense switch bad or mis-located

D. Control Board bad

A. See next section

B. Check connections / correct as needed

C. Adjust/replace as needed

D. Replace board

Loading...

Loading...