5-9

FUEL SYSTEM

PILOT SCREW ADJUSTMENT

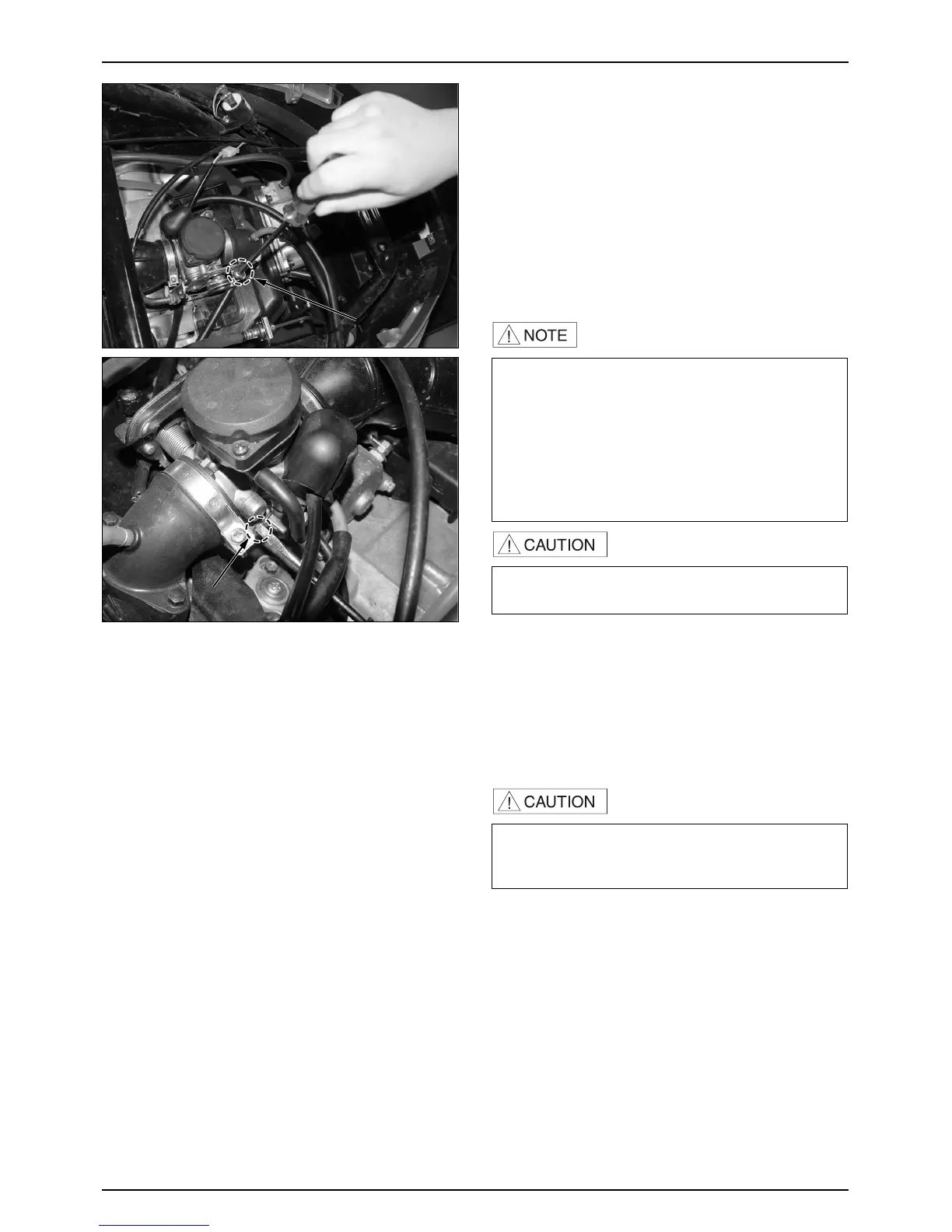

● Remove the carburetor maintenance cover. (⇨3-3)

① Turn the pilot screw clockwise until it seats lightly, then

back it out to the specification given (1½).

② Warm up the engine to operating temperature (60℃).

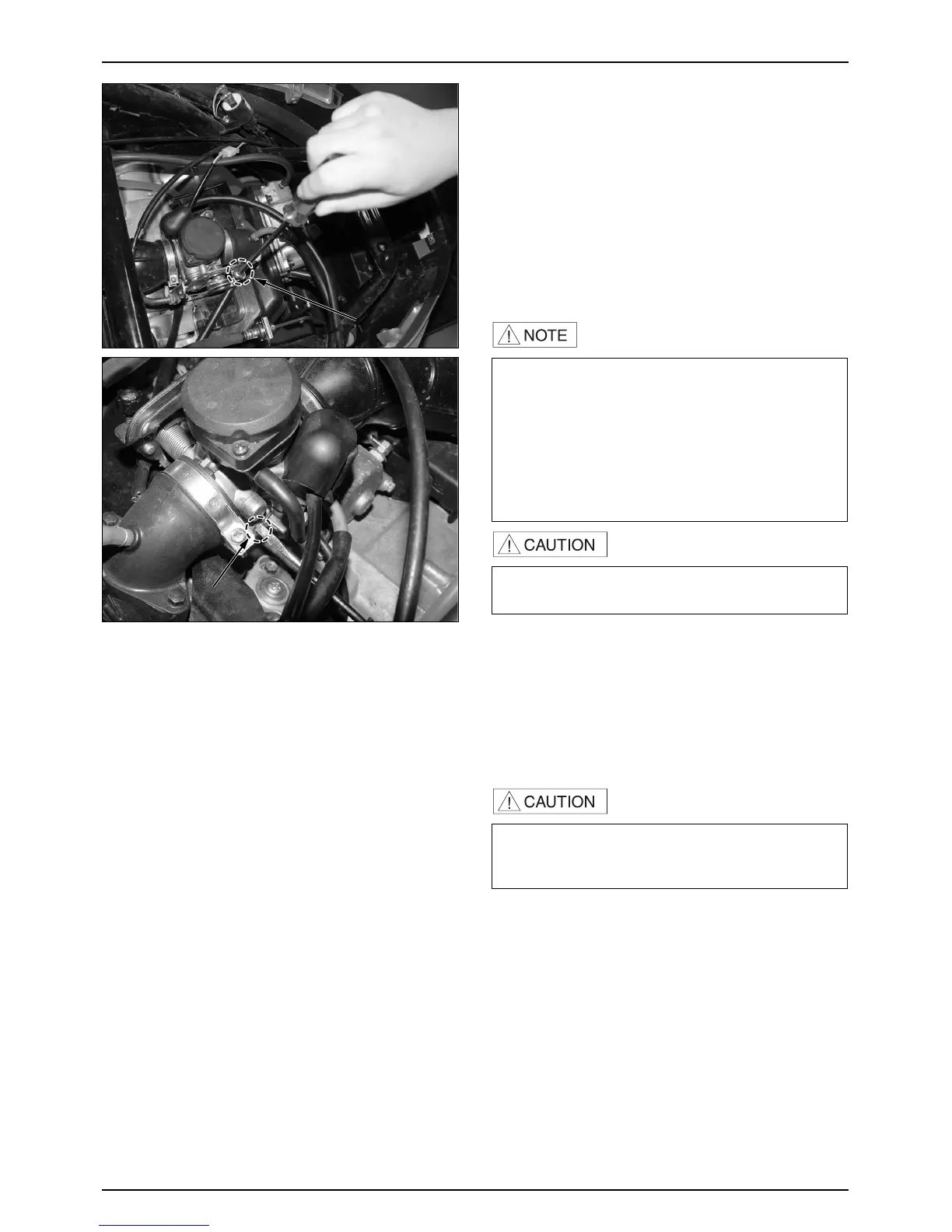

③ Adjust the idle speed with the throttle stop screw.

IDLE SPEED : 1,700

±

100 rpm

④ Rev the engine up slightly from the idle speed and

make sure that engine speed rises and returns smoothly.

⑤ When turning the throttle stop screw in gradually until

the engine speed drops 1,000rpm, make sure that the

engine does not run.

Adjust by turning the pilot screw with a ⅛ turn and

repeat steps ④ and ⑤

⑥ Readjust the idle speed with the throttle stop screw.

● Install the carburetor maintenance cover.

•The pilot screw is factory pre-set. Adjustment is not

necessary unless the caburetor is overhauled or a

new pilot screw is installed.

•Before adjusting the pilot screw, check the following

items.

-Fuel system, electrical system for troubling.

-Spark plug for cleaning and gap adjusting.

-Valve clearance for adjusting.

•Tightening the pilot screw against its seat will

damage the seat.

•If the engine cannot be adjusted by turning the pilot

screw within a ¼ turn, check for other engine

problems.

THROTTLE STOP SCREW

THROTTLE STOP SCREW

THROTTLE STOP SCREW

THROTTLE STOP SCREW

THROTTLE STOP SCREW

THROTTLE STOP SCREW

THROTTLE STOP SCREW

THROTTLE STOP SCREW

THROTTLE STOP SCREW

THROTTLE STOP SCREW

THROTTLE STOP SCREW

THROTTLE STOP SCREW

THROTTLE STOP SCREW

THROTTLE STOP SCREW

THROTTLE STOP SCREW

THROTTLE STOP SCREW

THROTTLE STOP SCREW

THROTTLE STOP SCREW

PILOT SCREW

PILOT SCREW

PILOT SCREW

PILOT SCREW

PILOT SCREW

PILOT SCREW

PILOT SCREW

PILOT SCREW

PILOT SCREW

PILOT SCREW

PILOT SCREW

PILOT SCREW

PILOT SCREW

PILOT SCREW

PILOT SCREW

PILOT SCREW

PILOT SCREW

PILOT SCREW

Loading...

Loading...