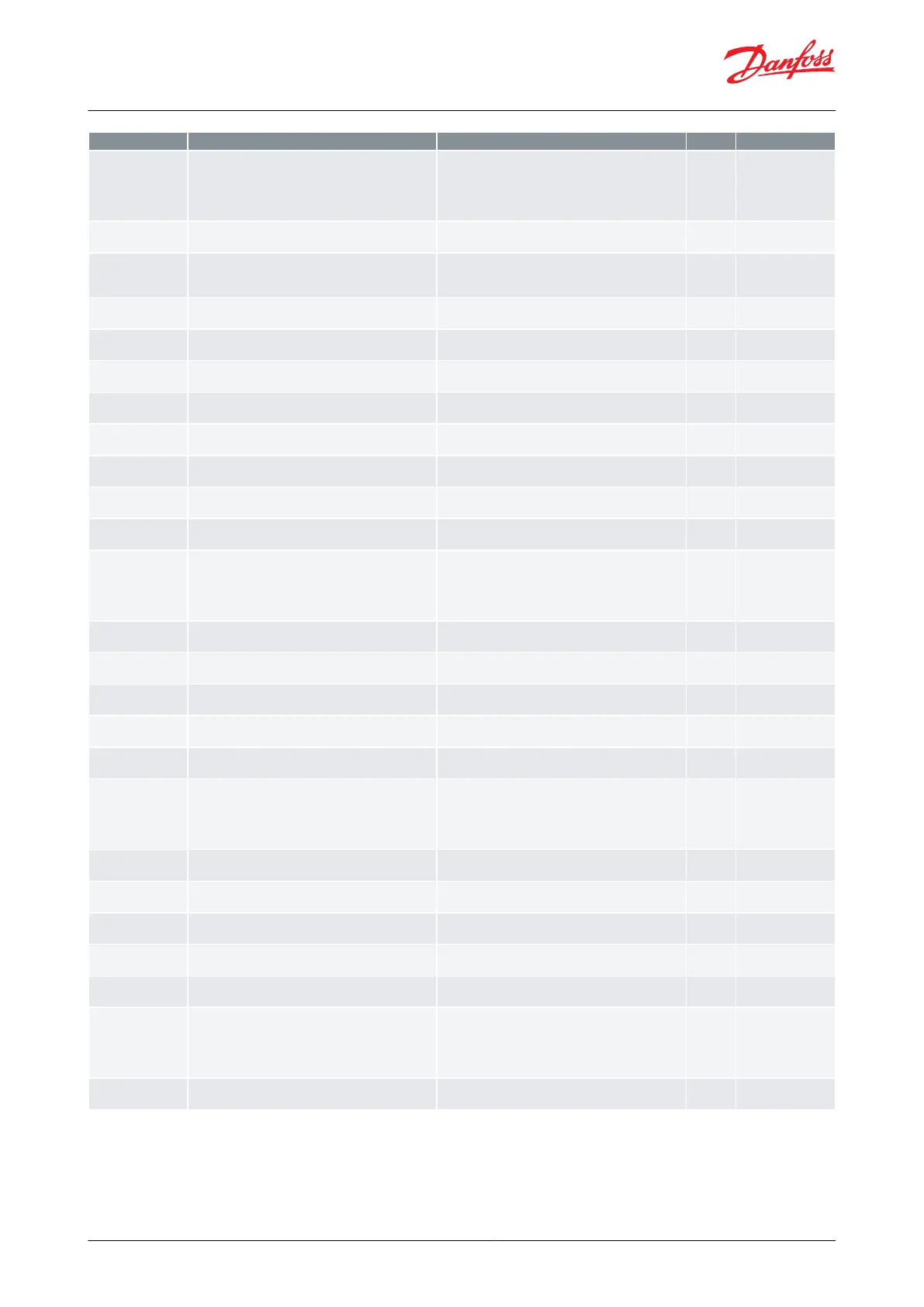

Setting of required stability of S2 gas outlet tempera-

ture before the superheat reference is reduced (Ex-

pert setting)A higher value will allow more instabillity

in S2 signalA lower value will allow less instabillity in

S2 signal

Expert injection setting - contact Danfoss for further

information

Gain factor for feedback of evaporating temperature

signal Te to the PI controller controlling the superheat

(expert setting)

Amplication factor for modulating temperature con-

trol (Expert setting)

Integration time for modulating temperature control

(Expert setting)

Expert injection setting - contact Danfoss for further

information

Expert injection setting - contact Danfoss for further

information

Expert setting - contact Danfoss for further informa-

tion

Expert readout - contact Danfoss for further informa-

tion

Expert setting - contact Danfoss for further informa-

tion

Calculated maximum opening degree of the injection

valve (expert readout)

Readout showing which part of the injection function

that is in control of the valve opening degree

Values must be changed as per below:

0=Adaptive SH control

1=MOP

2=Superheat close

3=MTR

Expert injection setting - contact Danfoss for further

information

Expert readout - contact Danfoss for further informa-

tion

Expert setting - contact Danfoss for further informa-

tion

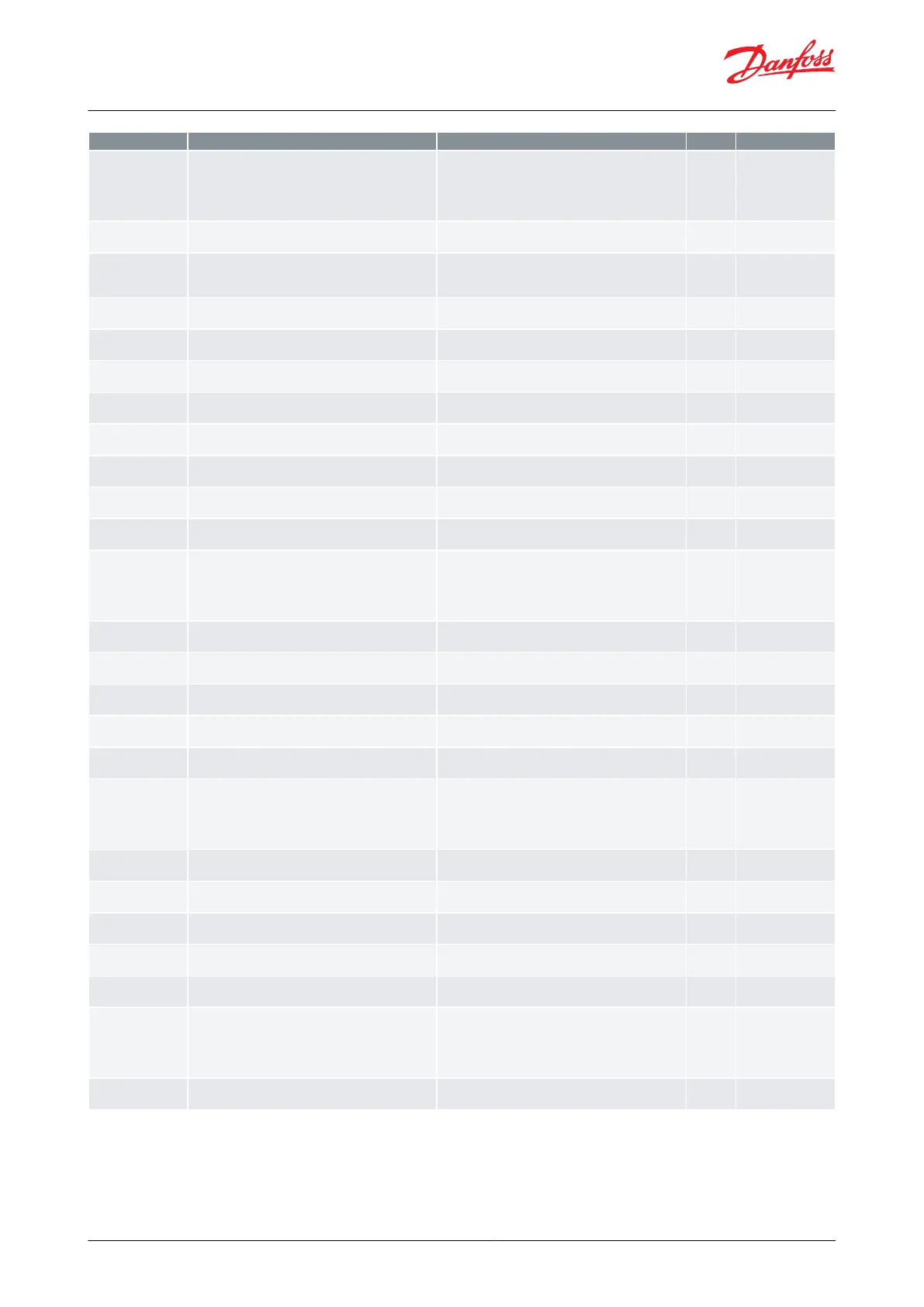

Expert injection setting - contact Danfoss for further

information

Calculated maximum opening degree of the injection

valve (expert readout)

Readout showing which part of the injection function

that is in control of the valve opening degree

Values must be changed as per below:

0=Adaptive SH control

1=MOP

2=Superheat close

3=MTR

Expert injection setting - contact Danfoss for further

information

Expert readout - contact Danfoss for further informa-

tion

Expert setting - contact Danfoss for further informa-

tion

Expert injection setting - contact Danfoss for further

information

Calculated maximum opening degree of the injection

valve (expert readout)

Readout showing which part of the injection function

that is in control of the valve opening degree

Values must be changed as per below:

0=Adaptive SH control

1=MOP

2=Superheat close

3=MTR

Expert injection setting - contact Danfoss for further

information

AK-CC55 Multi Coil

© Danfoss | Climate Solutions | 2022.08 BC365022028193en-000201 | 56

Loading...

Loading...