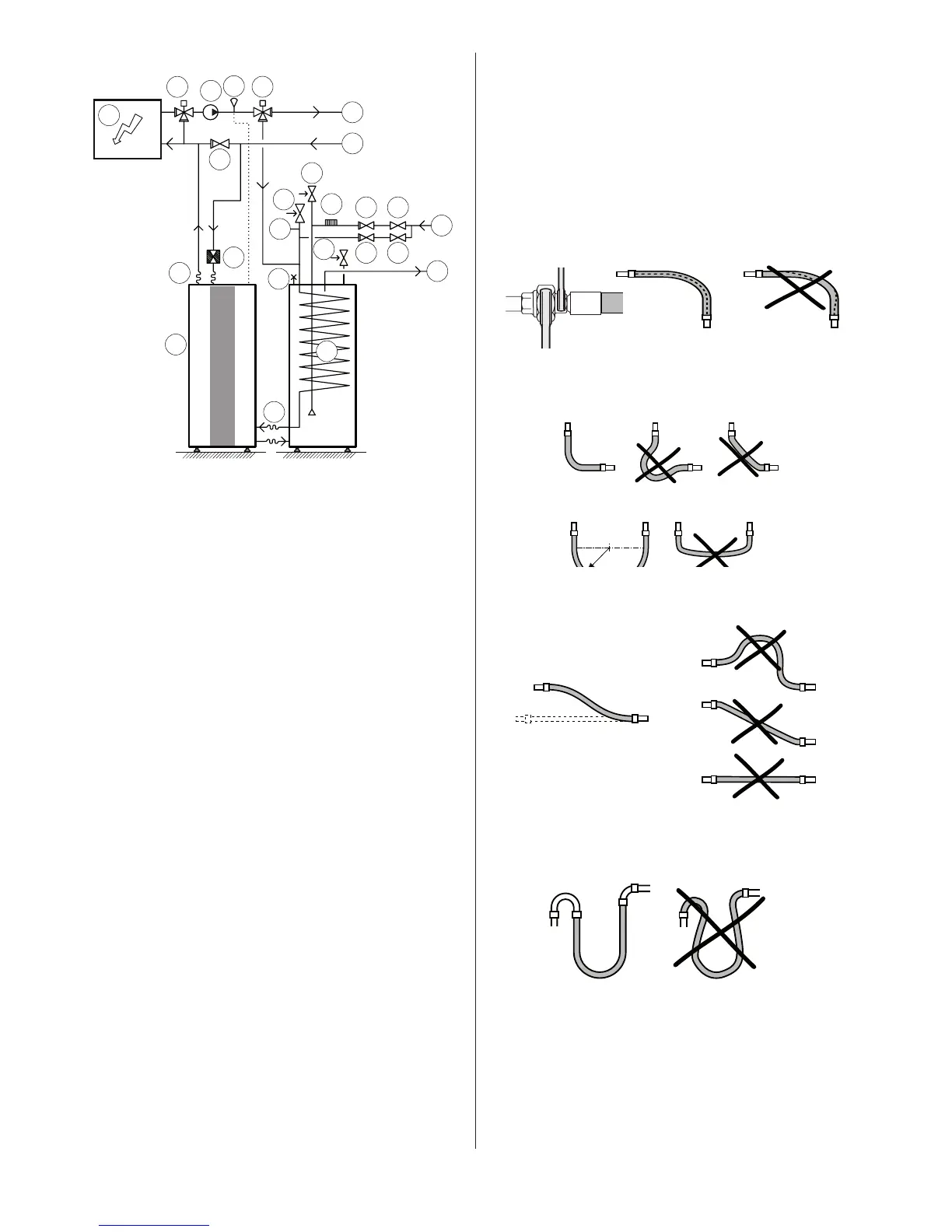

DHP-AL, connection diagram VLD

General connection diagram DHP-AL, system VLD.Figure 49:

Position Name

1 Heat pump (part of the delivery)

2 Supply line

3 Return line

4 Safety valve

5 Expansion tank

6 Strainer (part of the delivery)

7 Flexible hoses (part of the delivery)

8 -

9 Mixer valve

10 Exchange valve

11 Safety valve (9 bar) (included in delivery)

12 Vacuum valve

13 Non-return valve

14 Shut-off valve

15 Cold water

16 Hot water

17 Water heater (part of the delivery)

18 Bleed valve at stainless steel water heater

19 External auxiliary heater

20 Circulation pump

21 Non-return valve

22 Moved supply line sensor (included in heat pump)

23 Auxiliary shunt

24 Safety valve for temperature and pressure (mounted only on cer-

tain models, see chapter 6)

6.4 Safety valves

⚠

Radiator systems with a closed expansion tank must also be

equipped with an approved pressure gauge and safety valve,

minimum DN 20, for a maximum 1.5 bar opening pressure, or

according to country specific requirements.

⚠

Cold and hot water pipes as well as overflow pipes from

safety valves must be made of heat resistant and corrosion-

resistant material, e.g. copper. The safety valve overflow pipes

must have an open connection to the drain and visibly flow

into this in a frost-free environment.

⚠

The connecting pipe between the expansion tank and the

safety valve must slope continuously upwards. A continuous

upwards slope means that the pipe must not slope down-

wards from the horizontal at any point.

6.5 Connecting cold and hot water pipes

1. Connect the cold water and hot water pipes with all the neces-

sary components according to the connection diagram for the

relevant system.

6.6 Connecting the heating system supply

and return lines

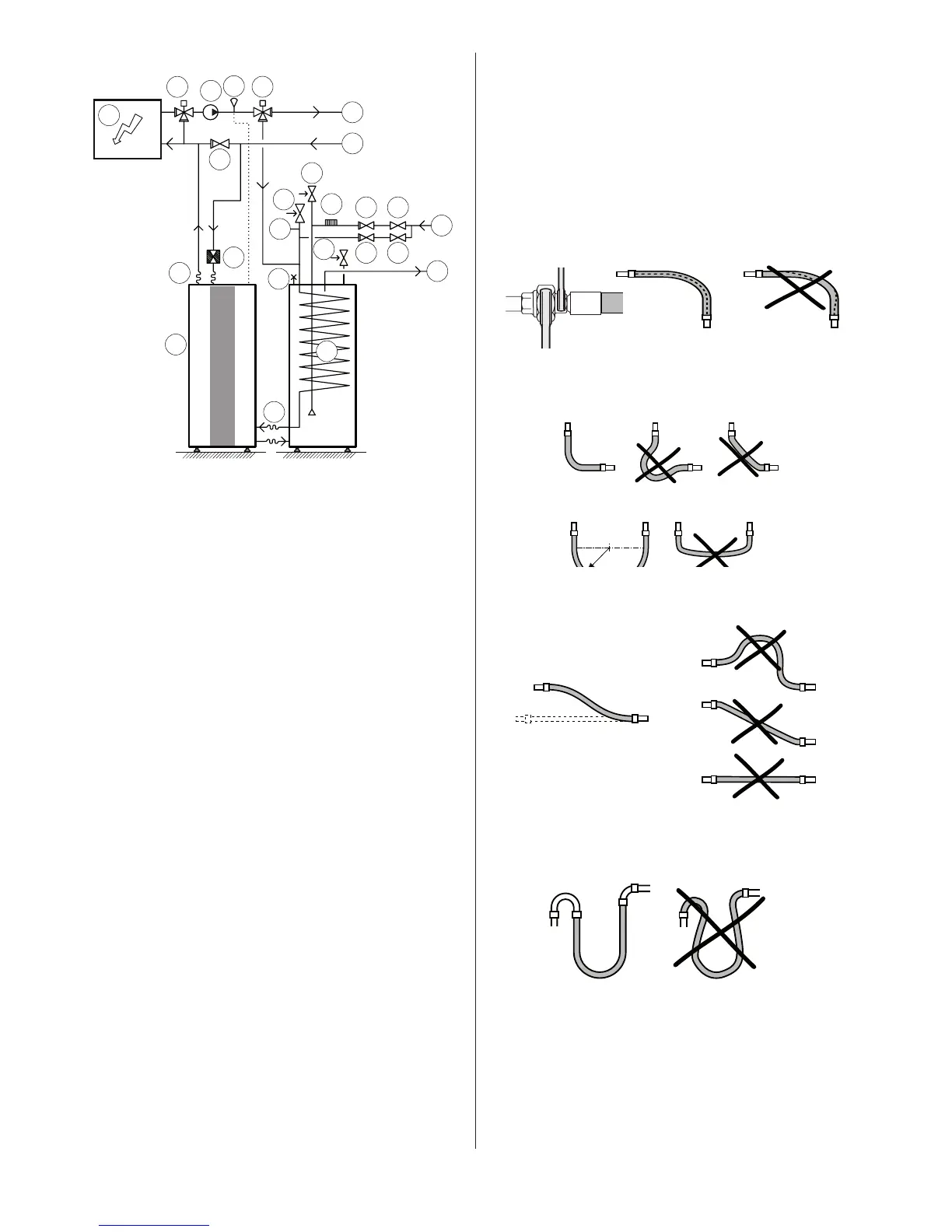

All pipes should be routed in such a way that vibrations cannot be

transmitted from the heat pump through the piping and out into

the building. This also applies to the expansion pipe. To avoid the

transmission of vibrations, we recommend that flexible hoses are

used for the supply line and return line on both the heating system

and brine system sides. Flexible hoses are available to purchase

from Danfoss AS. The figures below show how appropriate and

inappropriate installations look using this type of hose.

To avoid noise caused by pipe mounting, rubber-coated clamps should

be used to prevent the transmission of vibrations. However, installation

should not be too rigid and the clamps must not be too tight.

Do not twist the flexible hoses as they are installed. At Figure 50:

threaded connections, use a counterhold spanner.

Cut the hose to the correct length to avoid excess Figure 51:

bowingout or stretching at bends.

Cut the hose to the correct length to avoid excess bowing- Figure 52:

out or stretching and offset the ends so that the hose is not

installed completely straight.

Use fixed pipe bends to avoid excess stress on bends next to Figure 53:

connections.

1. Connect the supply line with a flexible hose connection and

with all the necessary components.

2. Connect the return line with a flexible hose connection and

with all the necessary components including a filter.

3. Insulate the supply and return lines.

4. Connect the expansion tank to the expansion outlet (22mm Cu)

on the top of the heat pump.

Loading...

Loading...