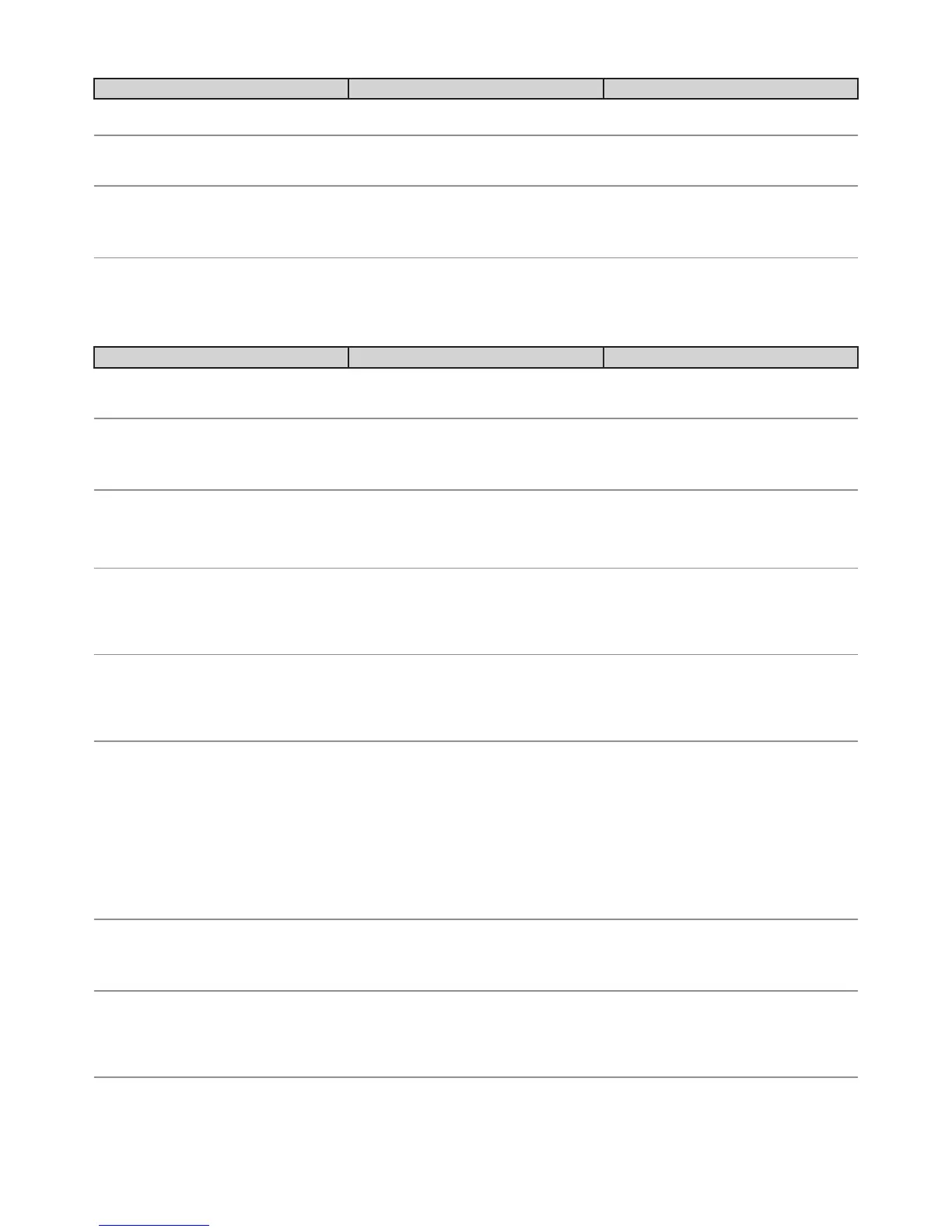

Problem – Noise – miscellaneous

Cause Troubleshooting Remedy

1. Vibrating protective sleeves on the pres-

sure switches.

Establish where the vibration noise is com-

ing from.

Prevent the protection sleeve vibrating by

using insulation tape for example.

2. Vibration noise from the electrical instal-

lation.

Check for electrical steps or similar devices

screwed to the heat pump and wall. These

can cause vibrations and noise.

Carry out according to the installation

instructions.

3. The heat pump is not level. Check that the heat pump is level by using

a spirit level.

Check that the heat pump is supported by

all four feet

If the heat pump is not level, adjust using

the feet.

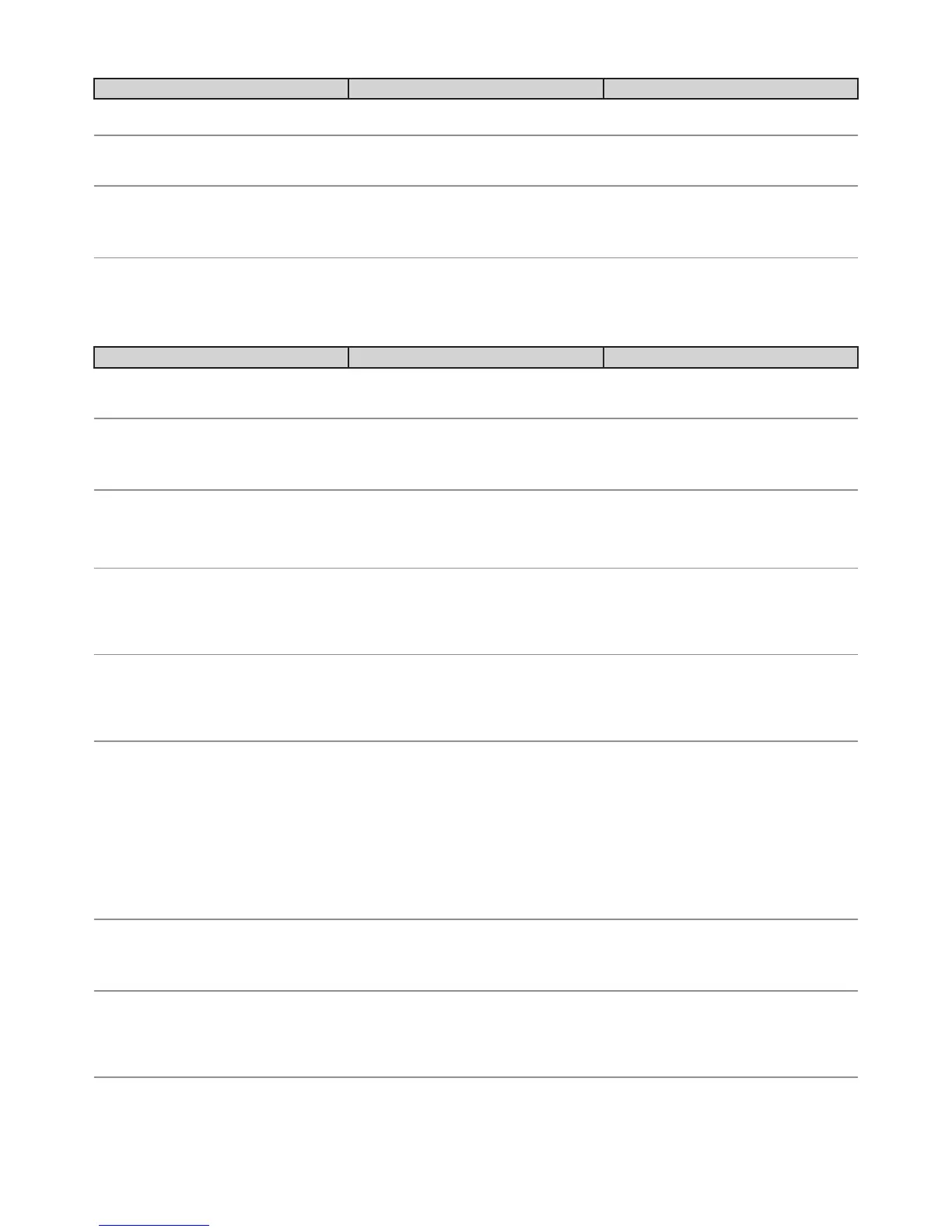

HOT WATER

Problem – Temperature and/or quantity

Cause Troubleshooting Remedy

1. Defective 3-way valve motor. Check the function of the 3-way valve, that

it runs between the end positions by run-

ning a manual test.

If the motor is defective, replace it.

2. Jammed 3-way valve insert.

The valve is not secure and releases hot

water to the radiators during hot water

production.

Detach the motor and test closing and

opening of the valve by pressing the con-

trol arm

If the insert jams, remove and clean it, or

replace it.

3. Air in TWS coil or water outer jacket. During hot water production:

•Listenforair.

•Checkthetemperaturedifference

between supply and return line.

Bleed the system.

A Large temperature difference can indicate

air in the system.

4. Start temperature set too high for hot

water production.

Check that the start temperature is correctly

set. Should not be set above the factory set

value.

•Ifthestartvalueissettoohigh,reduceit

to the factory set value.

•Ifthesystemhasahigh(>+8°C)brinetem-

perature, you may have to reduce the start

value further for a longer running time.

5. Sensor fault, hot water sensor.

Hot water production is started by the hot

water sensor.

Check what the hot water sensor (the start

sensor) shows, is it a plausible/actual value?

Measure the resistance of the sensor, check

against the ohm table in the Measurement

points section.

If the sensor is defective, replace it.

6. Large drain flow (>12l/min). Check how many litres of hot water (approx.

40°C) per minute drains from the tap. Use a

clock and bucket to measure the drain flow.

If the drain water flow is greater than 12l/

min, stratification in the water heater is

affected, which reduces the hot water

capacity.

Suggested corrective actions:

•Installapressurereductionvalveonthe

incoming cold water pipe.

•Changetoamixerwithlowerflow.

•Adjustthedrainflowontheexistingmixer,

do not open the tap fully.

7. Water heater too small in relation to

requirement.

How large is the requirement and what is

the capacity of the heater?

Replace with a larger heater or supplement

with an extra heater.

E.G. supplement with an MBH TWS or an

electric heater.

8. The operating pressure switch opens too

soon (at too low a pressure).

Hot water production ends when the oper-

ating pressure switch opens.

Check the break pressure using manometer

apparatus.

If the pressure switch opens at the incorrect

pressure, replace it.

The replacement pressure switch can be

installed on the service output (Schrader

valve)

Loading...

Loading...