5

VMBMA602

1

1

2

3

4

5

6

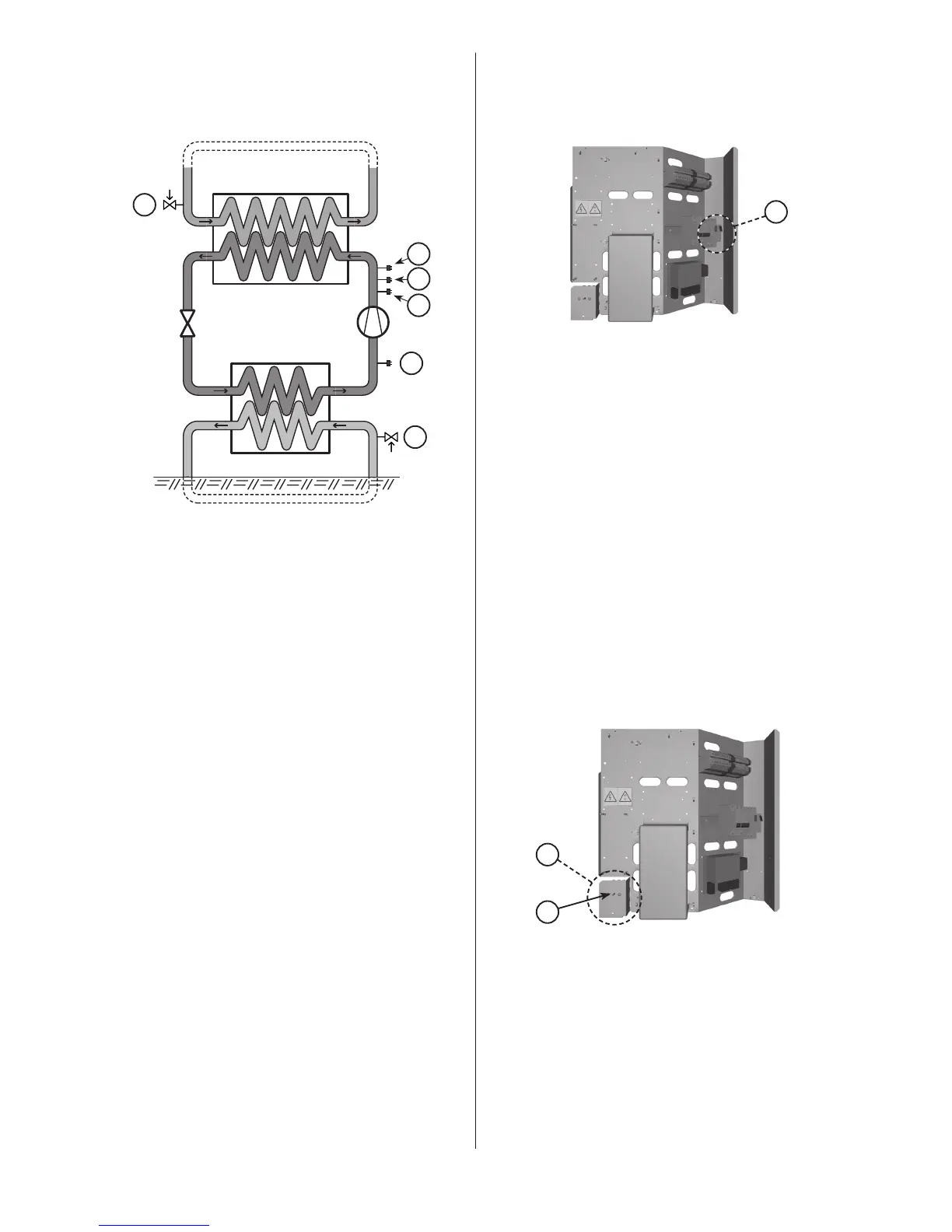

Heat transfer circuit

Refrigerant circuit

Brine circuit

1.4 Control and safety devices

To ensure a correct function of the heat pump there are a number

of control and safety devices.

The figure below shows the heat pump’s three liquid circuits with

respective safety function.

Control and safety devices.Figure 1:

Position Name

1 Safety valve, heat transfer circuit, external mounted.

2 Pressure switch, operation, 2,65 MPa

3 Pressure switch, operation, 2,85 MPa

4 Pressure switch, high pressure, 3,10 MPa

5 Pressure switch, low pressure, 0,08 Mpa

6 Safety valve, brine circuit, external mounted.

Heat transfer circuit

If the pressure in this circuit exceeds the opening pressure of the

safety valve (1), the valve opens to release the overflow and then

shuts again. The safety valve overflow pipe must have an open con-

nection to the drain and visibly flow into this in a frost-free environ-

ment.

Refrigerant circuit

The refrigerant circuit’s high pressure side is equipped with a high

pressure switch (4) and two operational pressure switches (2,3)

(only one is connected). The connected operational pressure switch

stops the compressor when the switching point is reached, that is,

when sufficient amount of heat is produced.

If the operational pressure switch should fail and the pressure

continue to rise, the compressor is stopped by the high pressure

switch when its switching point is reached. The operation of the

heat pump is blocked. When the problem with the abnormally high

pressure is solved, the pressure switch is automatically reset.

If the high pressure switch is tripped the alarm indicator on the

front panel is flashing and an alarm text is displayed. Restart the

heat pump by first setting the operational mode to OFF and then

back to previous mode (AUTO/HEATPUMP/ADD.HEAT/HOT WATER).

The low pressure switch (5) stops the compressor if the pressure is

too low on the low pressure side. The operation of the heat pump

is blocked. When the problem with the abnormally low pressure is

solved, the pressure switch is automatically reset.

If the low pressure switch is tripped the alarm indicator on the front

panel is flashing and an alarm text is displayed. Restart the heat

pump by first setting the operational mode to OFF and then back

to previous mode (AUTO/HEATPUMP/ADD.HEAT/HOT WATER).

Brine circuit

If the pressure in this circuit exceeds the opening pressure of the

safety valve (6), the valve opens to release the overflow and then

shuts again. The safety valve overflow pipe must have an open con-

nection to the drain and visibly flow into this in a frost-free environ-

ment.

Compressor

The compressor is equipped with a thermal overload relay which

protects the compressor from over current.

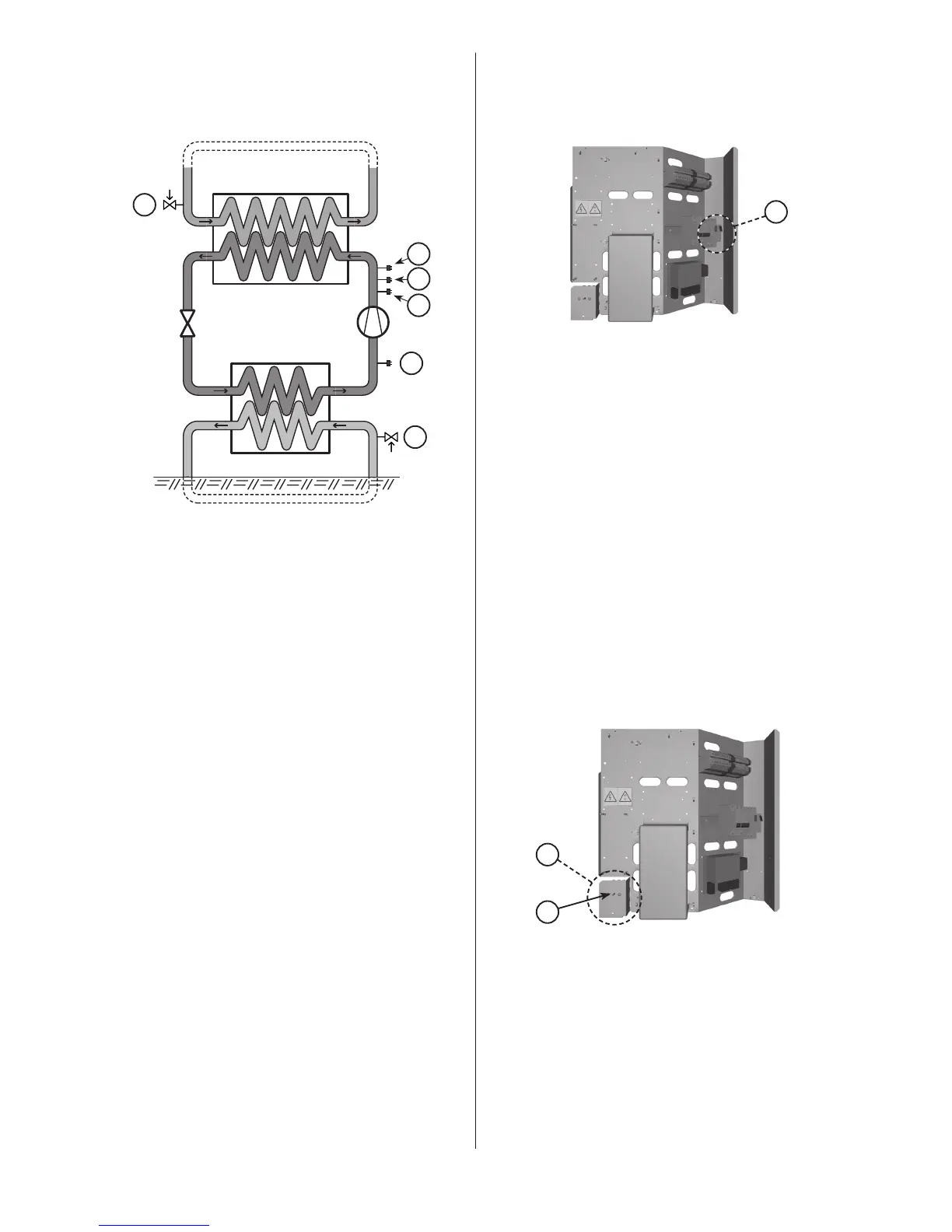

The thermal overload relay on the electrical panel.Figure 2:

Position Name

1 Thermal overload relay (F11)

If the thermal overload relay is tripped the alarm indicator on the

front panel is flashing and an alarm text is displayed.

The thermal overload relay must cool down and it is automatically

reset. The alarm is acknowledged by setting the operational mode

to OFF and then back to previous mode (AUTO/HEATPUMP/ADD.

HEAT/HOT WATER).

The compressor is also equipped with an internal protection which

stops the compressor’s operation if it risks being overheated. The

internal protection cannot be reset manually, the compressor must

cool down before it can start operation.

Circulation pumps

A circulation pump has an internal overload protection. It is reset

automatically when the pump has cooled down.

However, a pump in a 10 to 16kW heat pump (air 8-12kW) has an

internal overload relay that trips the motor protection alarm. The

indication and reset are the same as for the compressor.

Auxiliary heat

The auxiliary heater is made up of an electric heating element on

the supply line. It is equipped with a temperature guard which

stops the heating element’s operation if it risks being overheated.

The temperature guard is placed on the electrical panel.

The temperature guard on the electrical panel.Figure 3:

Position Name

1 Temperature guard

2 Reset button

If the temperature guard is tripped the alarm indicator on the front

panel is flashing and an alarm text is displayed.

The temperature guard is reset by pushing the reset button (2).

⚠

The temperature guard must be reset by authorised person-

nel only.

Specifications

Please see the technical data tables at the end of this manual for

detailed specifications.

1

2

Loading...

Loading...