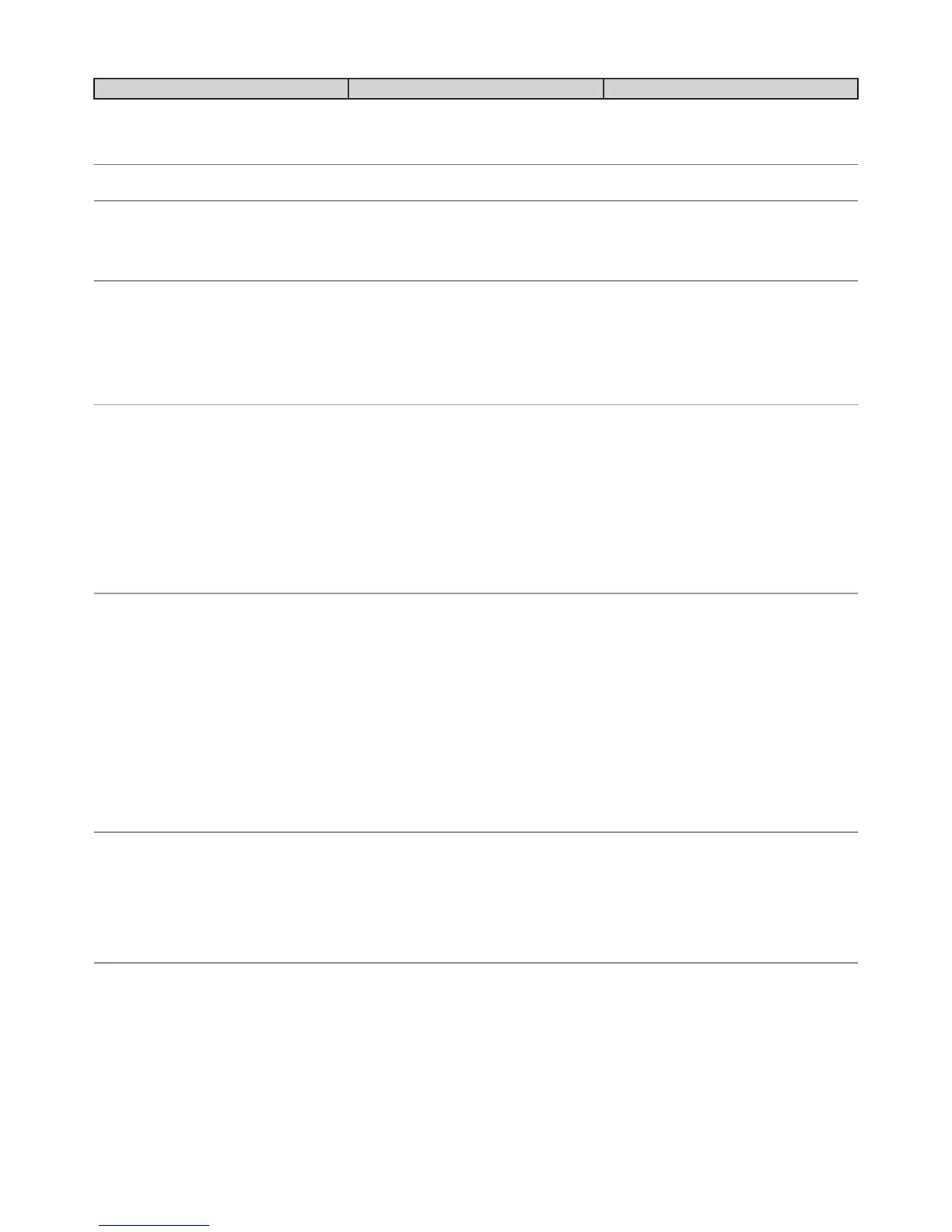

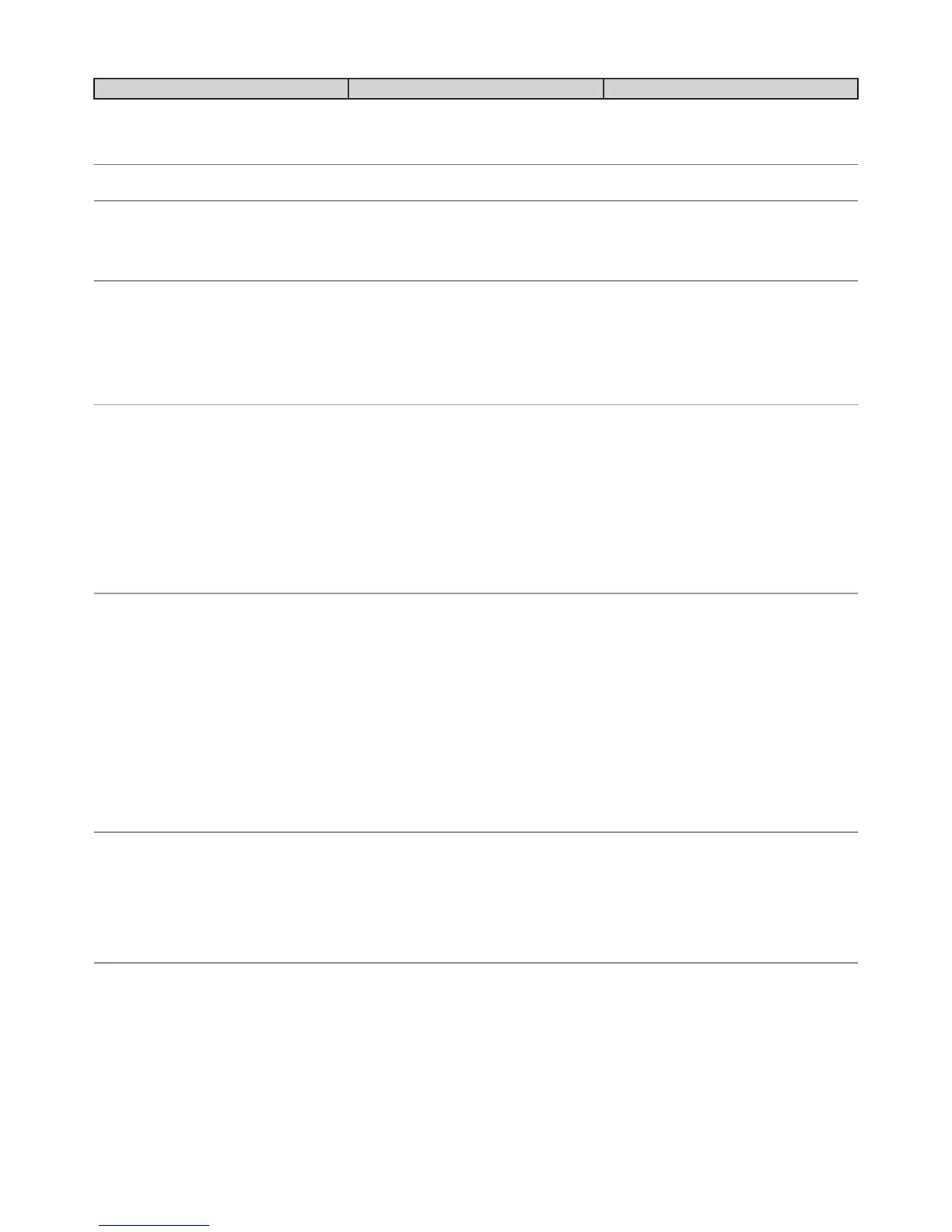

Problem – Runs on electric heating element

Cause Troubleshooting Remedy

1. Operating mode ADD.HEAT is selected. If this operating mode is selected, the aux-

iliary heater is used for heating and hot

water production, not the compressor.

If ADD.HEAT mode is selected and you no

longer want it, change to AUTO, the heat

pump then controls both the compressor

and auxiliary heater.

2. The compressor cannot run due to an

alarm.

Check the alarm that is indicated in the

display.

Rectify the problem and rest the alarm. See

the Operational problem – Alarm, section.

3. The integral value has reached the start

level for the auxiliary heater.

Check what the integral value is in the con-

trol computer.

If the auxiliary heater is in operation

because the integral value has counted

down to the start value, the computer

reacts as it should, see the Heat pump for

further information.

4. Peak heat operation (legionella function)

is running.

Check if the heat pump runs peak heat. See

the instructions for the relevant model.

Peak heat operation occurs in connection

with hot water production with the set

interval. The compressor should then start

to produce hot water and 2 minutes later

the auxiliary heater starts, the compressor

should then stop and the stop temperature

is reached with only the auxiliary heater

connected. Take no corrective action.

5. The heat pump has stopped on HIGH

RETURN.

•CheckwhattheMAXRETURNvalueisset

at in the heat pump’s control computer. It

must be adjusted to the unit’s maximum

supply temperature and the system’s delta

temperature so that it does not cut at too

high a return temperature when the highest

supply temperature is transmitted.

•Checkwhatthereturnlinesensorshows,

is it a plausible/actual value? If not, take

a resistance reading from the sensors

and check against the ohm table in the

Measurement points section.

If the MAX RETURN value is not adjusted for

the system according to the troubleshoot-

ing window, adjust it.

If the sensor is defective, replace it.

6. The compressor runs backwards. The

incoming phases have the incorrect

sequence (only applies to 3-phase heat

pumps).

If the compressor runs backwards, it will

not cope with compressing the refrigerant

and therefore does not produce the correct

power, which leads to the control computer

requesting auxiliary heating.

•IfthetextERRPHASESEQappearsinthe

display when the heat pump is powered,

(only appears in the first 10 minutes) this

means that the phases have the incorrect

sequence.

•Whenthecompressorisrunning,check

the delivery pipe temperature by feeling

the delivery pipe that should be hot (not

just warm) even a little distance from the

compressor if the phases are correctly

sequenced.

•Whenthecompressorrunswiththephas-

es incorrectly sequenced a strange noise

may be heard (loud, rattling) when the

compressor runs backwards.

If the phases are in the incorrect order,

switch two incoming phases at the main

terminal block and recheck according to the

troubleshooting window.

7. Changed conditions. Have you increased

your heating and/or hot water demand?

•Iftheheatpumphasbeendimensioned

for a certain demand and this demand is

increased, the heat pump might not be able

to maintain the desired room temperature.

•Ifhotwaterconsumptionincreases,a

larger proportion of time is used to produce

hot water, which means less time for heat

production (only applies to VL-systems).

If the heat pump cannot cope with the

demand, replace it with one with a higher

output or supplement it with a higher out-

put auxiliary heater.

Loading...

Loading...