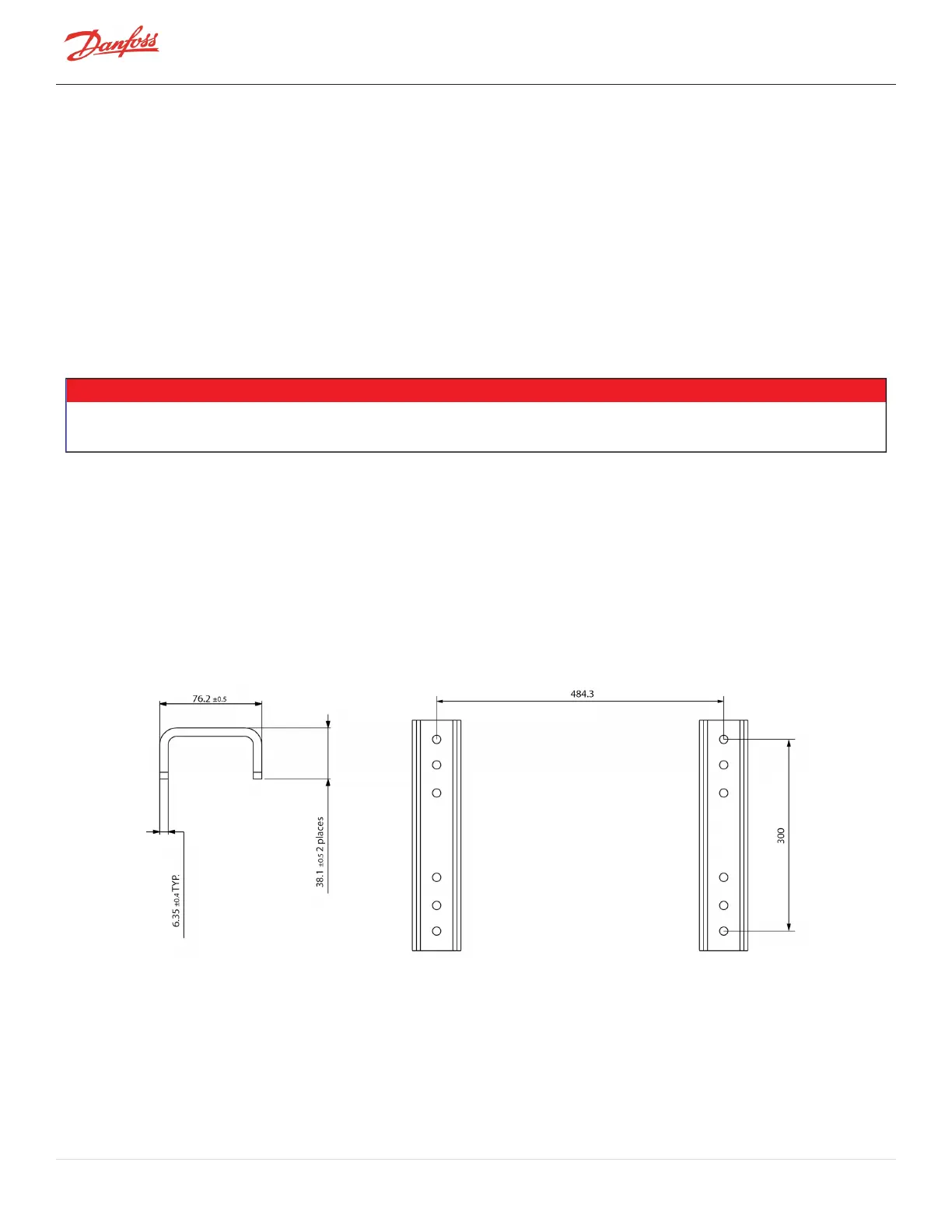

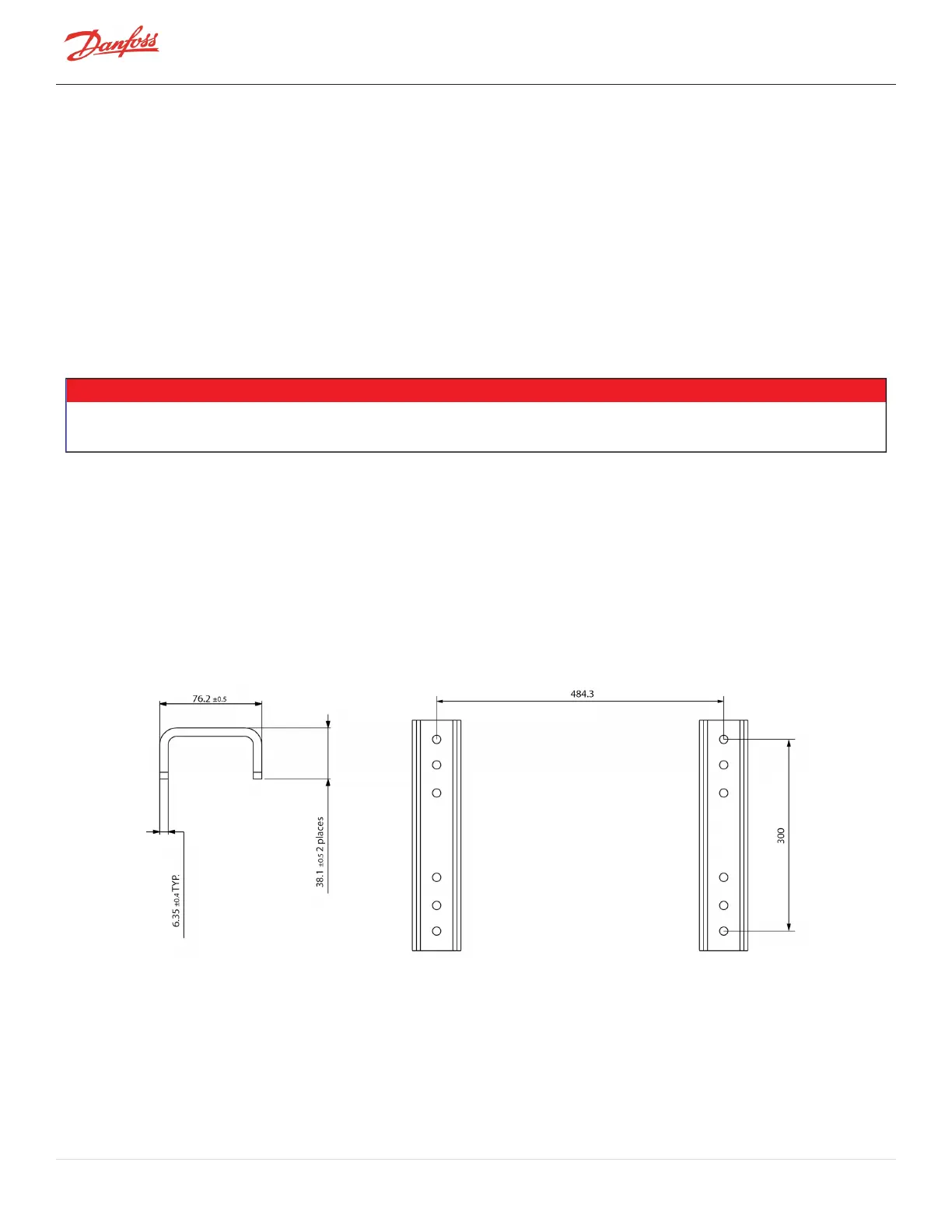

20.4 Mounting Base

The compressor must be mounted on a rigid surface of sufficient structural integrity to support the weight of the

compressor and valves. Refer to the following figures and table for further details.

l Figure 16-10 TTH/TGH Center of Gravity Capacitor Side View

l Figure 1-9 Center of Gravity Top View (Excluding TTH/TGH Compressors

l Figure 16-10 TTH/TGH Center of Gravity Capacitor Side View

l Figure 1-11 TTH/TGH Center of Gravity Top View

l Table 1-2 Center of Gravity X-Y Coordinates

A mounting kit is available to isolate the compressor from the supporting structure and to minimize vibration from

other rotating equipment. The compressor mounting rails should be level ± 3/16” (5 mm) in the lateral and

longitudinal planes.

NOTE

If isolation pads are used at the four mounting base points, the overall height of the compressor will change. Be sure to measure

accordingly based on the insulator used.

1. If isolation pads are used, install four pads in accordance with the footprint dimensions given in Figure

20-2 Mounting Base (TTS/TGS/TTH/TGH) Series.

2. Mount the compressor onto the isolation pads. Ensure the compressor mounting rails are properly

isolated from the base frame once the attaching hardware is secured; for example, the screw should

not extend from the compressor mounting rails to the base frame Figure 20-3 Incorrect Compressor

Mounting Pad Installation and Figure 20-4 Correct Compressor Mounting Pad Installation.

3. Check that the compressor mounting rails are level ± 5 mm (3/16”) in the lateral and longitudinal

planes.

Figure 20-2 Mounting Base (TTS/TGS/TTH/TGH) Series

Page 116 of 136 - M-AP-001-EN Rev. S 9/8/2021

Loading...

Loading...