Chapter 6.0 Electrical Specifications

6.1 Supply Voltage and Frequency

Turbocor compressors are designed to operate with a power supply that is within an acceptable tolerance for each

nominally rated voltage and frequency. The tables below specify the acceptable supply voltage and frequency

ranges. Using a supply voltage/frequency at or beyond the range limit will cause the compressor to shut down.

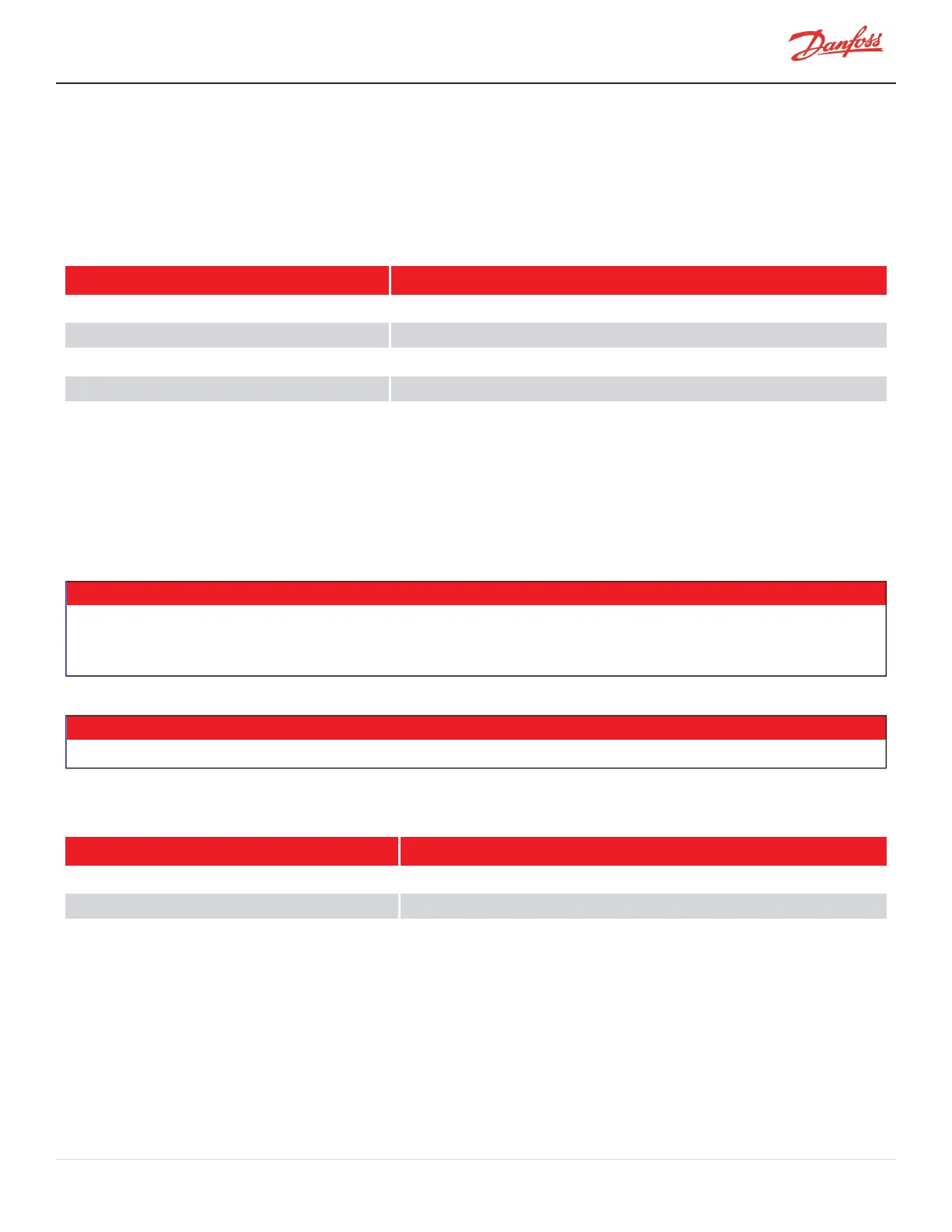

Table 6-1 Acceptable AC Voltage Range

Nominal Voltage Acceptable Voltage Range

380V 342 - 418 VAC

400V 360 - 440 VAC

460V 414 - 506 VAC

575V 518 - 635 VAC

6.2 Voltage Sag Immunity

Danfoss TTS/TGS Series Turbocor Compressors comply with SEMI F47-0706 and have been certified by a 3rd party

testing agency tested in accordance with IEC 61000-4-34. Turbocor compressors meet the criteria of SEMI F47 based

on 7.8.2 section (c) which allows for equipment that is a subsystem and/or component to pass by recovery without

operator interface. In the event of a compressor fault, Turbocor compressors are able to be reset/run remotely via

the OEMs' chiller controllers upon clearing of any active fault.

• • • CAUTION • • •

Application of a compressor to any voltage which is outside of the nominal rated voltage defined on the compressor nameplate will result

in voiding of the compressor warranty from Danfoss LLC, unless otherwise stated by Danfoss LLC. This includes any application of a 400V

compressor in a 380V application without the use of a transformer to correct the voltage going into the compressor.

NOTE

Refer to the TTS/TGS Compressor Nomenclature section of this manual for details on the compressor voltage availability.

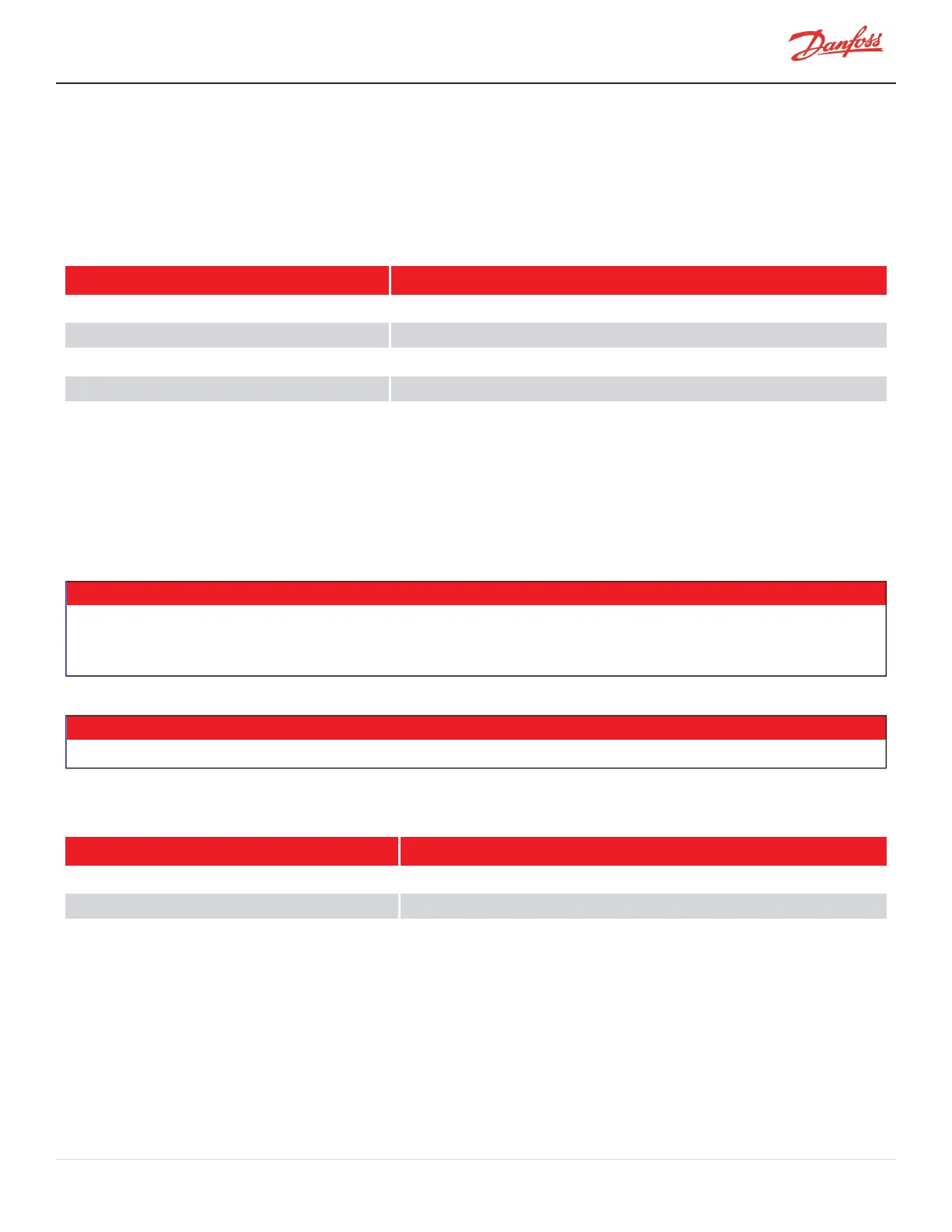

Table 6-2 Acceptable Frequency Range

Nominal Frequency Acceptable Frequency Range

50Hz 50Hz ±5% (47Hz-53Hz)

60Hz 60Hz ±5% (57Hz-63Hz)

6.3 Compressor Current Limit and Operating Range Settings

The new compressor controller (version 3.0.0 and above; Table 1-1 Application Manual Applicability Scope) is

designed to allow a user to configure the current setting based on the intended application. The compressor defines

the Full Load Ampere (FLA) and Locked Rotor Ampere (LRA) as a range on the nameplate. The settings for the FLA

and LRA are adjustable using the Service Monitoring Tool (SMT) or directly from the customer controller application.

The 3-Phase Over Current Alarm FLA cannot be set higher than the 3-Phase Over-Current Fault limit LRA. The

maximum fault limit and alarm limit settings are dependent upon the Voltage and Model. The Model type defines

the range for the FLA and LRA values.

M-AP-001-EN Rev. S-9/8/2021 Page 45 of 136

Loading...

Loading...