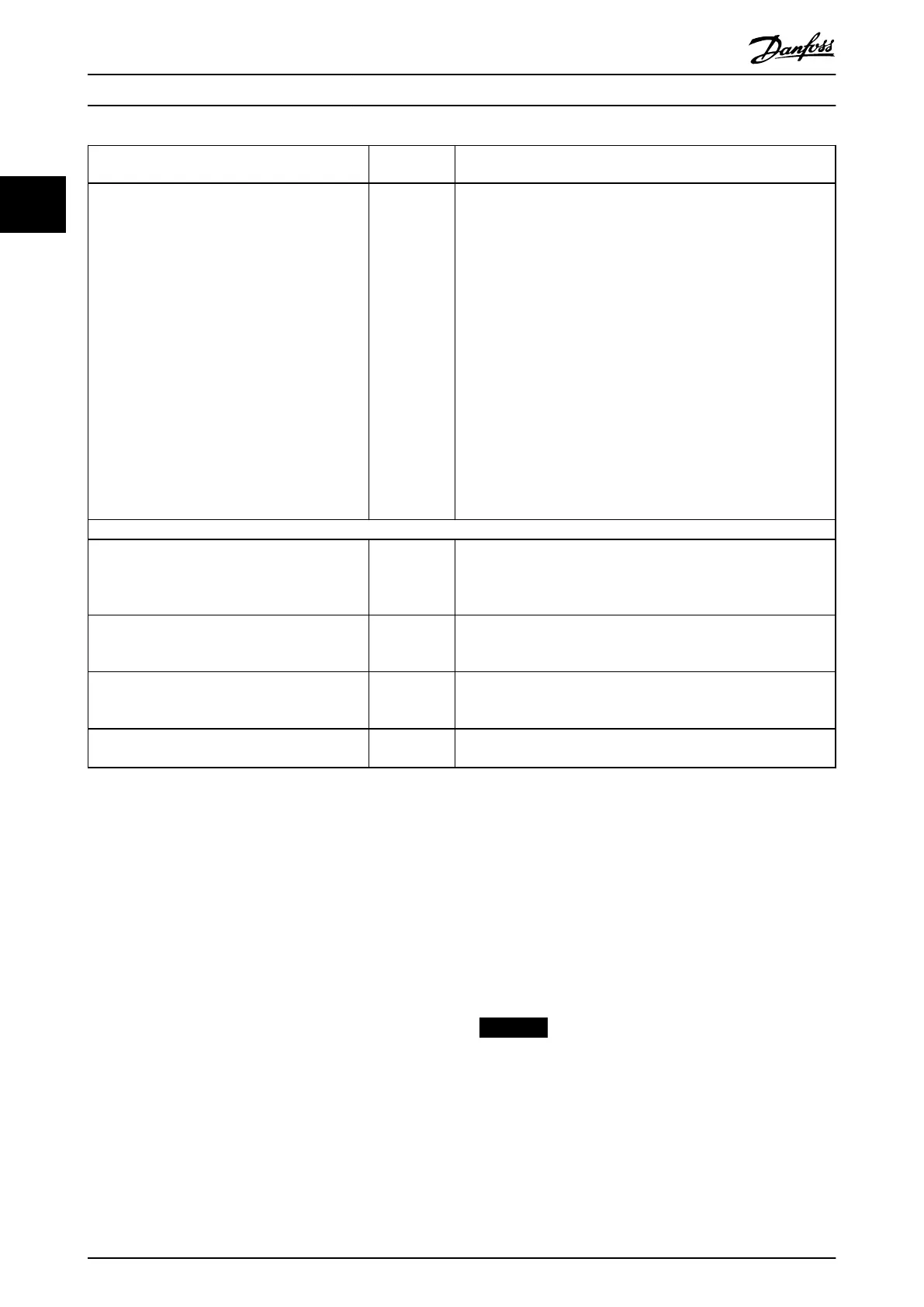

Function Parameter

number

Setting

Set terminal 53 low voltage.

Set terminal 53 high voltage.

Set terminal 54 low feedback value.

Set terminal 54 high feedback value.

Set feedback source.

Parameter 6-10

Terminal 53

Low Voltage

Parameter 6-11

Terminal 53

High Voltage

Parameter 6-24

Terminal 54

Low Ref./Feedb.

Value

Parameter 6-25

Terminal 54

High Ref./

Feedb. Value

Parameter 7-20

Process CL

Feedback 1

Resource

0 V

10 V

-5 °C (23 °F)

35 °C (95 °F)

[2] Analog input 54

6) Basic PID settings:

Process PID normal/inverse. Parameter 7-30

Process PID

Normal/

Inverse Control

[0] Normal

Process PID anti wind-up. Parameter 7-31

Process PID

Anti Windup

[1] On

Process PID start speed. Parameter 7-32

Process PID

Start Speed

300 RPM

Save parameters to LCP. Parameter 0-50

LCP Copy

[1] All to LCP

Table 2.10 Example of Process PID Control Set-up

2.5.5 Process Controller Optimization

After conguring the basic settings as described in

chapter 2.5.5 Programming Order, optimize the proportional

gain, the integration time, and the dierentiation time

(parameter 7-33 Process PID Proportional Gain,

parameter 7-34 Process PID Integral Time, and

parameter 7-35 Process PID Dierentiation Time). In most

processes, complete the following procedure:

1. Start the motor.

2. Set parameter 7-33 Process PID Proportional Gain

to 0.3 and increase it until the feedback signal

again begins to vary continuously. Reduce the

value until the feedback signal has stabilized.

Lower the proportional gain by 40–60%.

3. Set parameter 7-34 Process PID Integral Time to 20

s and reduce the value until the feedback signal

again begins to vary continuously. Increase the

integration time until the feedback signal

stabilizes, followed by an increase of 15–50%.

4. Only use parameter 7-35 Process PID Dierentiation

Time for fast-acting systems (dierentiation time).

The typical value is 4 times the set integration

time. Use the dierentiator when the setting of

the proportional gain and the integration time

has been fully optimized. Make sure that the

lowpass lter dampens the oscillations on the

feedback signal suciently.

NOTICE

If necessary, start/stop can be activated several times to

provoke a variation of the feedback signal.

Product Overview

VLT

®

Midi Drive FC 280

34 Danfoss A/S © 03/2016 All rights reserved. MG07B102

22

Loading...

Loading...